Direct drive technology eliminates the need for belts or gears, offering increased efficiency and reduced maintenance in mechanical systems. It delivers smoother operation, enhanced precision, and quieter performance, making it ideal for applications like electric vehicles and industrial machinery. Discover how direct drive can revolutionize your equipment by reading the full article.

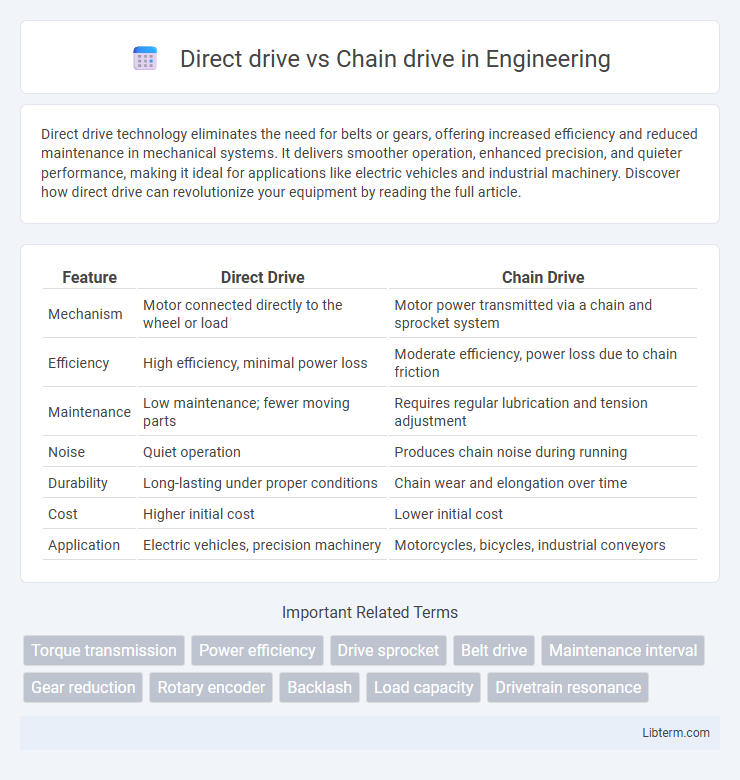

Table of Comparison

| Feature | Direct Drive | Chain Drive |

|---|---|---|

| Mechanism | Motor connected directly to the wheel or load | Motor power transmitted via a chain and sprocket system |

| Efficiency | High efficiency, minimal power loss | Moderate efficiency, power loss due to chain friction |

| Maintenance | Low maintenance; fewer moving parts | Requires regular lubrication and tension adjustment |

| Noise | Quiet operation | Produces chain noise during running |

| Durability | Long-lasting under proper conditions | Chain wear and elongation over time |

| Cost | Higher initial cost | Lower initial cost |

| Application | Electric vehicles, precision machinery | Motorcycles, bicycles, industrial conveyors |

Introduction to Drive Systems

Direct drive systems transfer power from the motor directly to the wheel, enhancing efficiency and reducing maintenance by eliminating intermediary components. Chain drive systems use a chain and sprockets to transmit power, offering flexibility in gear ratios but requiring regular lubrication and tension adjustments. Understanding the fundamental differences in mechanics and maintenance needs is crucial for selecting the optimal drive system for bicycles, motorcycles, or industrial machinery.

What is Direct Drive?

Direct drive systems transfer power directly from the motor to the wheel or load without intermediary components like chains or belts, resulting in higher efficiency and reduced maintenance. They are commonly used in electric bicycles, turntables, and industrial machinery due to their quiet operation and improved torque delivery. This design minimizes energy loss, enhances reliability, and provides smoother performance compared to traditional chain drive mechanisms.

What is Chain Drive?

Chain drive is a mechanical system that transmits power between two rotating shafts using a chain and sprockets, commonly found in bicycles, motorcycles, and industrial machinery. It offers efficient power transfer, durability, and ease of maintenance compared to other drive systems. Chain drives provide a reliable method for motion transfer where high torque and consistent speed ratios are essential.

Key Differences Between Direct Drive and Chain Drive

Direct drive systems transfer power directly from the motor to the wheel, resulting in higher efficiency, lower maintenance, and quieter operation compared to chain drive systems. Chain drive mechanisms use a chain and sprocket to deliver power, offering easier repairability and typically lower initial costs but require regular lubrication and tension adjustments. Key differences include durability, noise levels, maintenance demands, and power transmission efficiency, influencing the choice between direct drive and chain drive in applications like bicycles and electric scooters.

Efficiency Comparison: Direct Drive vs Chain Drive

Direct drive systems provide higher efficiency by minimizing energy loss due to fewer moving parts and the elimination of chain friction and stretching. Chain drive efficiency typically ranges from 85% to 98%, while direct drive systems can achieve efficiency levels above 90%, often closer to 95% or higher under optimal conditions. Maintenance requirements are lower for direct drives, contributing to sustained efficiency over time with less performance degradation.

Maintenance Requirements

Direct drive systems require significantly less maintenance compared to chain drive systems due to the absence of exposed moving parts and lubrication needs. Chain drives demand regular cleaning, lubricating, and tension adjustments to prevent wear and rust, which increases upkeep time and costs. The durability and sealed design of direct drive mechanisms reduce maintenance frequency, enhancing overall reliability and longevity.

Noise and Vibration Levels

Direct drive systems generate significantly lower noise and vibration levels compared to chain drive mechanisms due to the absence of physical links and reduced mechanical friction. The direct coupling of motor and wheel minimizes operational disturbances, resulting in smoother, quieter performance ideal for indoor or noise-sensitive environments. Chain drives often produce louder mechanical noise and vibrations because of chain tension, gear engagement, and wear over time.

Cost Considerations

Direct drive systems generally have higher upfront costs due to advanced engineering and precision components, but they offer lower maintenance expenses over time since they eliminate the need for chain lubrication and tension adjustments. Chain drive setups are more affordable initially, making them popular for budget-conscious buyers, though ongoing costs accumulate from regular chain replacements, stretching, and lubrication requirements. Evaluating total cost of ownership reveals that direct drive may provide better long-term value despite its initial price premium, especially in applications demanding reliability and minimal upkeep.

Ideal Applications for Each Drive System

Direct drive systems excel in applications requiring high precision, low maintenance, and quiet operation, such as turntables, electric vehicles, and high-performance robotics. Chain drive systems are ideal for heavy-duty, high-torque applications like bicycles, motorcycles, and industrial machinery due to their durability and ease of repair. Selecting between direct drive and chain drive depends on factors like torque requirements, maintenance preferences, and noise sensitivity.

Conclusion: Choosing the Right Drive System

Selecting the appropriate drive system depends on specific needs such as maintenance, efficiency, and noise levels. Direct drive systems offer higher energy efficiency, reduced maintenance, and quieter operation, making them ideal for applications demanding precision and longevity. Chain drive systems provide affordability and ease of repair, suited for scenarios where initial cost and simplicity are prioritized.

Direct drive Infographic

libterm.com

libterm.com