Cascade control enhances process stability by using two controllers where one regulates the primary variable and the other manages a secondary variable as a disturbance or setpoint input. This hierarchical approach minimizes lag and improves system response by addressing disturbances more quickly than single-loop control. Discover how implementing cascade control can optimize your process performance in the full article.

Table of Comparison

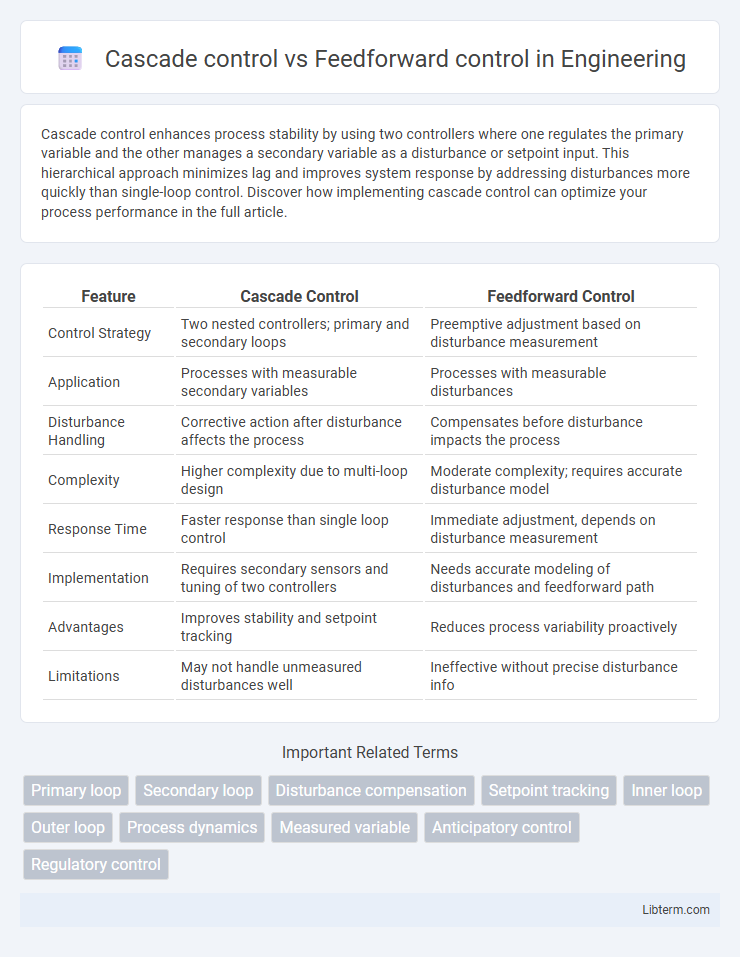

| Feature | Cascade Control | Feedforward Control |

|---|---|---|

| Control Strategy | Two nested controllers; primary and secondary loops | Preemptive adjustment based on disturbance measurement |

| Application | Processes with measurable secondary variables | Processes with measurable disturbances |

| Disturbance Handling | Corrective action after disturbance affects the process | Compensates before disturbance impacts the process |

| Complexity | Higher complexity due to multi-loop design | Moderate complexity; requires accurate disturbance model |

| Response Time | Faster response than single loop control | Immediate adjustment, depends on disturbance measurement |

| Implementation | Requires secondary sensors and tuning of two controllers | Needs accurate modeling of disturbances and feedforward path |

| Advantages | Improves stability and setpoint tracking | Reduces process variability proactively |

| Limitations | May not handle unmeasured disturbances well | Ineffective without precise disturbance info |

Introduction to Control Strategies

Cascade control involves a hierarchical structure where a primary controller regulates the setpoint of a secondary controller, enhancing disturbance rejection and system stability in complex processes. Feedforward control anticipates disturbances by measuring them directly and adjusting the control input proactively, improving response time and reducing errors before they occur. Both strategies optimize process performance but differ in their approach to disturbance management and system dynamics.

Fundamentals of Cascade Control

Cascade control involves two or more controllers arranged hierarchically, where the primary controller sets the setpoint for the secondary controller to improve system response and disturbance rejection. The secondary controller acts on a faster dynamic variable, allowing more precise and stable control of complex processes compared to single-loop control. This hierarchical structure significantly enhances disturbance compensation by addressing disturbances at multiple points within the control loop.

Fundamentals of Feedforward Control

Feedforward control fundamentally anticipates disturbances by measuring them before they affect the process, allowing corrective actions to be applied proactively. Unlike cascade control, which relies on feedback from secondary loops to adjust the primary loop, feedforward control does not depend on deviation signals, enhancing system responsiveness and stability. This approach requires an accurate model of the process and disturbance dynamics to predict and counteract changes effectively, minimizing variability and improving steady-state performance.

Key Differences Between Cascade and Feedforward Control

Cascade control employs two feedback controllers where the primary controller regulates the setpoint of the secondary controller to enhance disturbance rejection and improve system stability, whereas feedforward control anticipates disturbances by measuring them directly and compensating before they affect the process variable. Cascade control is effective for managing interactions between multiple control loops and delays, while feedforward control requires an accurate disturbance model to provide proactive correction. The key difference lies in cascade's hierarchical feedback strategy versus feedforward's disturbance-based corrective action without relying on process output feedback.

Advantages of Cascade Control Systems

Cascade control systems offer superior disturbance rejection by utilizing a secondary controller to manage intermediate variables, resulting in faster response and improved stability compared to single-loop or feedforward control. These systems enhance overall process control accuracy by compensating for measurable disturbances and nonlinearities within the process. Cascade control is particularly beneficial in applications with significant time delays or complex dynamics, ensuring smoother control and reduced overshoot.

Advantages of Feedforward Control Systems

Feedforward control systems offer superior disturbance rejection by anticipating changes and adjusting the process variables before deviations occur, minimizing errors and improving system stability. These systems provide faster response times compared to cascade control, as they do not rely solely on feedback from the output but directly measure disturbances. Enhanced accuracy in maintaining setpoints and reduced energy consumption are key advantages that make feedforward control ideal for processes with measurable disturbances.

Limitations of Cascade Control

Cascade control offers improved disturbance rejection by using a primary and secondary controller, but it faces limitations such as increased complexity and difficulty in tuning multiple controllers simultaneously. The secondary controller must operate faster than the primary one to be effective, which can be challenging in processes with slow secondary dynamics. Moreover, cascade control is less effective when secondary variable sensors are inaccurate or when disturbances are unpredictable, limiting its applicability compared to feedforward control.

Limitations of Feedforward Control

Feedforward control can struggle with model inaccuracies and external disturbances that were not anticipated during the design phase, leading to suboptimal system performance. It requires precise knowledge of the process and disturbances, making it less effective in dynamic environments with unpredictable changes. Unlike cascade control, it lacks corrective feedback, which limits its ability to compensate for real-time variations and unmodeled disturbances.

Applications and Case Studies

Cascade control excels in applications requiring precise temperature regulation in chemical reactors by using a primary controller to set a secondary controller's setpoint, enhancing stability and response time. Feedforward control is highly effective in process industries like wastewater treatment, where disturbances such as inlet flow variations are measured and compensated before affecting the system output, improving disturbance rejection. Case studies in power plants demonstrate cascade control maintaining steam temperature, while feedforward control optimizes ingredient mixing in food processing by adjusting inputs based on raw material variability.

Choosing the Right Control Strategy

Selecting the appropriate control strategy depends on process dynamics and disturbance characteristics; cascade control excels in managing processes with slow primary loops and measurable secondary variables, offering enhanced disturbance rejection through multi-layered feedback. Feedforward control suits processes with measurable disturbances affecting the output, allowing proactive correction before the primary feedback loop responds, improving stability and reducing offset. Combining both strategies can optimize performance in complex systems where disturbance measurement and multi-variable control are critical.

Cascade control Infographic

libterm.com

libterm.com