Hall effect sensors detect magnetic fields by measuring voltage changes caused by the Hall effect, enabling precise position, speed, and current sensing in various applications like automotive and industrial systems. These sensors offer high reliability, contactless operation, and fast response times, making them essential components in modern electronic devices. Discover how a Hall effect sensor can enhance Your project's performance by exploring the full article.

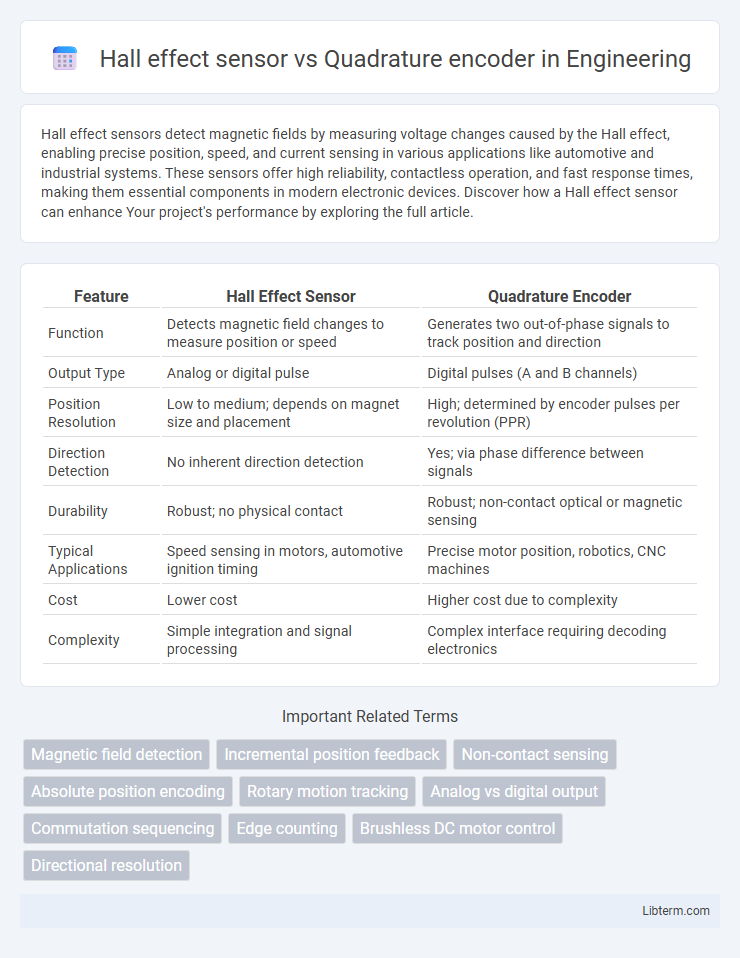

Table of Comparison

| Feature | Hall Effect Sensor | Quadrature Encoder |

|---|---|---|

| Function | Detects magnetic field changes to measure position or speed | Generates two out-of-phase signals to track position and direction |

| Output Type | Analog or digital pulse | Digital pulses (A and B channels) |

| Position Resolution | Low to medium; depends on magnet size and placement | High; determined by encoder pulses per revolution (PPR) |

| Direction Detection | No inherent direction detection | Yes; via phase difference between signals |

| Durability | Robust; no physical contact | Robust; non-contact optical or magnetic sensing |

| Typical Applications | Speed sensing in motors, automotive ignition timing | Precise motor position, robotics, CNC machines |

| Cost | Lower cost | Higher cost due to complexity |

| Complexity | Simple integration and signal processing | Complex interface requiring decoding electronics |

Introduction to Hall Effect Sensors and Quadrature Encoders

Hall effect sensors detect magnetic fields by measuring voltage changes induced by a magnetic flux, providing precise position or speed measurements in various applications. Quadrature encoders generate two output signals in a phase-shifted manner, enabling accurate direction and displacement tracking by decoding pulse sequences. Both devices are essential in motion control systems, with Hall effect sensors offering contactless operation and quadrature encoders delivering high-resolution incremental feedback.

Working Principle: Hall Effect Sensor vs Quadrature Encoder

Hall effect sensors operate by detecting changes in magnetic fields, generating a voltage proportional to the magnetic flux density when a magnetic object passes nearby. Quadrature encoders utilize two output signals with a 90-degree phase difference to determine direction and position through counting pulses generated by optical or magnetic sensing elements. While hall effect sensors measure magnetic field variations directly for speed or position, quadrature encoders provide higher resolution feedback by decoding rotational movement through phase-shifted signals.

Key Differences in Signal Output

Hall effect sensors produce a single digital pulse or analog voltage corresponding to the magnetic field strength, making them ideal for detecting position or speed with simpler output signals. Quadrature encoders generate two out-of-phase digital square wave signals (Channel A and Channel B) enabling precise direction and position tracking by interpreting the phase difference between these signals. The Hall effect sensor's output is often simpler and less detailed, while the quadrature encoder provides higher resolution and directional information critical for complex motion control applications.

Accuracy and Resolution Comparison

Hall effect sensors offer moderate accuracy and resolution, typically suitable for basic position sensing with resolution limits around a few degrees due to their analog or digital output nature. Quadrature encoders provide significantly higher accuracy and resolution, often reaching up to thousands of counts per revolution, enabling precise angular position and speed measurements. This makes quadrature encoders ideal for applications demanding fine motion control and detailed feedback compared to the coarser output inherent in Hall effect sensors.

Typical Applications of Hall Effect Sensors

Hall effect sensors are commonly used in automotive ignition systems, brushless DC motor position sensing, and proximity detection due to their ability to accurately measure magnetic fields without physical contact. They are ideal for speed detection and rotational position sensing in applications such as wheel speed sensors, tachometers, and gear-tooth sensors. Compared to quadrature encoders, Hall effect sensors offer simpler installation and robustness in harsh environments, making them suitable for industrial automation and consumer electronics.

Typical Applications of Quadrature Encoders

Quadrature encoders are widely used in robotics and industrial automation to provide precise position and speed feedback for motor control systems. Their applications include CNC machines, conveyor belt monitoring, and elevator control, where accurate motion detection is critical. Hall effect sensors are more common in low-cost speed sensing and simple position detection tasks but lack the resolution and direction detection capabilities of quadrature encoders.

Environmental Robustness and Durability

Hall effect sensors exhibit superior environmental robustness due to their solid-state design, offering resistance to dust, moisture, and vibration without mechanical wear. Quadrature encoders, especially mechanical optical types, are more susceptible to contamination and physical damage, leading to reduced durability in harsh environments. Magnetic quadrature encoders improve robustness but still generally fall short of the maintenance-free longevity provided by Hall effect sensors in challenging operational conditions.

Cost Considerations and Implementation Complexity

Hall effect sensors generally offer a lower cost solution due to their simpler construction and ease of integration in applications requiring basic rotational position detection. Quadrature encoders, while more expensive, provide higher precision and enable complex motion control, but their implementation requires advanced signal processing and careful alignment. Choosing between the two depends on budget constraints and the desired accuracy level in the application.

Integration and Compatibility with Control Systems

Hall effect sensors offer straightforward integration with control systems due to their simple digital output and compatibility with microcontrollers and PLCs, making them ideal for speed and position sensing in automotive and industrial applications. Quadrature encoders provide detailed rotational position and direction information through two-phase signals, requiring specialized decoder interfaces or microcontrollers with quadrature decoding capabilities, thus offering more precise control in robotics and CNC machines. While Hall effect sensors are generally easier to interface, quadrature encoders deliver higher resolution and improved feedback accuracy suitable for complex motion control systems.

Choosing the Right Technology for Your Project

Hall effect sensors offer reliable, contactless position detection ideal for simple rotation sensing and low-speed applications, utilizing magnetic field variations to generate signal output. Quadrature encoders provide precise, high-resolution feedback for speed and position control by producing two out-of-phase signals, enabling accurate direction and displacement measurement. Selecting between these technologies depends on project requirements for accuracy, speed, environmental conditions, and budget constraints, with Hall sensors favored for cost-effectiveness and durability, while quadrature encoders suit applications demanding detailed motion analysis.

Hall effect sensor Infographic

libterm.com

libterm.com