A cantilever is a rigid structural element anchored at only one end, allowing it to extend horizontally without external bracing. This design efficiently supports loads by transferring forces back to the fixed support, commonly seen in bridges, balconies, and overhanging structures. Explore the article to understand how cantilevers can enhance your construction projects with their unique load-bearing capabilities.

Table of Comparison

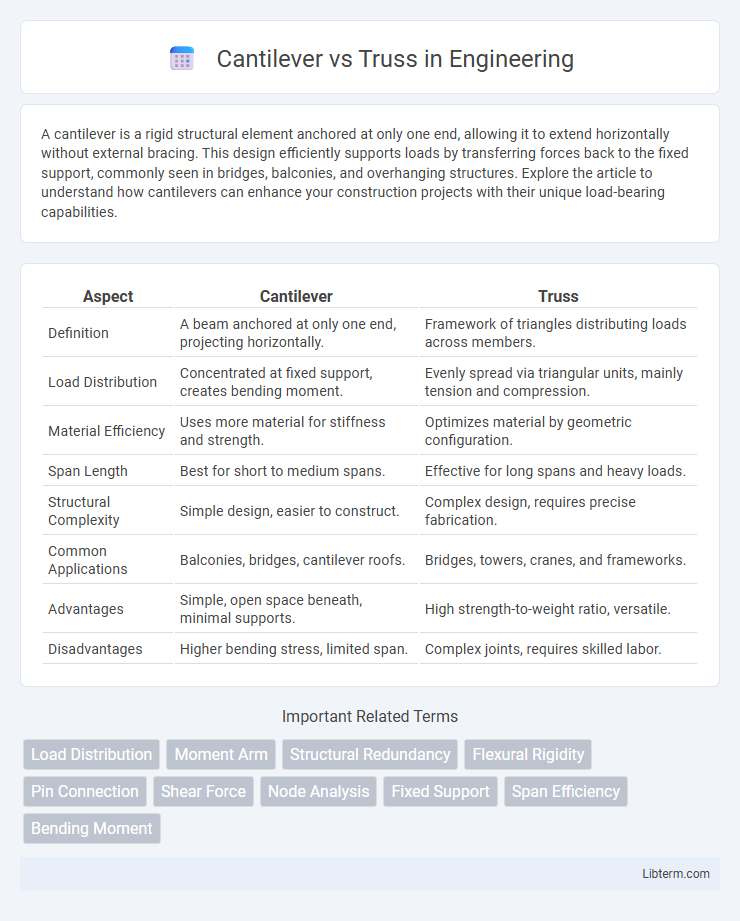

| Aspect | Cantilever | Truss |

|---|---|---|

| Definition | A beam anchored at only one end, projecting horizontally. | Framework of triangles distributing loads across members. |

| Load Distribution | Concentrated at fixed support, creates bending moment. | Evenly spread via triangular units, mainly tension and compression. |

| Material Efficiency | Uses more material for stiffness and strength. | Optimizes material by geometric configuration. |

| Span Length | Best for short to medium spans. | Effective for long spans and heavy loads. |

| Structural Complexity | Simple design, easier to construct. | Complex design, requires precise fabrication. |

| Common Applications | Balconies, bridges, cantilever roofs. | Bridges, towers, cranes, and frameworks. |

| Advantages | Simple, open space beneath, minimal supports. | High strength-to-weight ratio, versatile. |

| Disadvantages | Higher bending stress, limited span. | Complex joints, requires skilled labor. |

Introduction to Cantilever and Truss Structures

Cantilever structures extend horizontally and are supported only at one end, allowing for overhanging designs without additional support. Truss structures consist of interconnected triangles that distribute loads efficiently through tension and compression, providing stability and strength. While cantilevers excel in projects requiring minimal support, trusses are ideal for spanning large distances with reduced material use.

Key Differences Between Cantilever and Truss

Cantilever structures extend horizontally and are supported at only one end, providing significant overhang without additional supports, while truss structures consist of interconnected triangular elements that distribute loads evenly across multiple supports. Cantilevers are frequently used for balconies and bridges requiring projection without obstruction, whereas trusses are common in roof frameworks and large-span bridges for maximizing strength with minimal material. Load distribution in cantilevers relies heavily on bending moments, while trusses primarily handle axial forces, resulting in different design approaches and material efficiencies.

Structural Principles of Cantilevers

Cantilevers rely on fixed support at one end to bear loads, creating moments that induce tension on the upper fibers and compression on the lower fibers of the beam. Their structural principle centers on resisting bending through moment equilibrium and shear forces, enabling overhanging structures without intermediate supports. Unlike trusses that distribute loads through interconnected triangular elements, cantilevers depend on beam stiffness and material strength to maintain structural integrity.

Structural Design of Trusses

Truss structures optimize load distribution by using interconnected triangular units, enhancing stability and minimizing material usage through efficient force transfer. In contrast to cantilever designs that project horizontally and bear loads at one end, trusses distribute weight across multiple connections, reducing bending moments and deflections. Advanced structural analysis of trusses involves calculating axial forces in members to ensure integrity under varying loads, making them ideal for bridges, roofs, and towers.

Material Considerations for Cantilever and Truss

Cantilever structures typically require materials with high tensile strength and stiffness, such as steel or reinforced concrete, to resist bending moments and shear forces effectively. Truss systems benefit from lightweight yet strong materials like aluminum or high-strength steel, optimizing load distribution through triangular units to minimize material usage. Both structures demand careful material selection to balance durability, weight, and cost while ensuring structural integrity under dynamic and static loads.

Load Distribution and Stability Comparison

Cantilever structures transfer loads primarily through bending moments and shear forces concentrated at the fixed support, resulting in significant tension and compression within the beam. Truss systems distribute loads more efficiently by channeling forces through interconnected triangular units, converting bending stresses into axial forces in the members, enhancing stability. The inherent redundancy in truss designs provides greater load distribution and resilience against structural failure compared to the typically singular support system of cantilevers.

Advantages of Cantilever Structures

Cantilever structures offer unmatched flexibility in design due to their ability to extend horizontally without external bracing, making them ideal for bridges, balconies, and overhangs. Their load distribution reduces the need for multiple supports, resulting in less material usage and lower construction costs compared to truss designs. The simplicity of cantilever construction allows for faster installation in challenging environments, enhancing efficiency in urban developments and waterfront projects.

Benefits of Truss Systems

Truss systems provide superior load distribution through interconnected triangular units, enhancing overall structural stability and reducing material usage. Their modular design allows for efficient spanning of long distances with minimal deflection, making them ideal for bridges, roofs, and large buildings. The high strength-to-weight ratio of trusses also facilitates easier transportation and faster construction compared to cantilever alternatives.

Common Applications in Architecture and Engineering

Cantilever structures are commonly used in bridges, balconies, and overhanging roofs due to their ability to support loads without external bracing. Truss systems are prevalent in roof supports, bridges, and towers, offering efficient load distribution through interconnected triangular units. Both structural types optimize material use and stability but are selected based on specific architectural and engineering requirements such as span length and load conditions.

Choosing Between Cantilever and Truss: Decision Factors

Choosing between cantilever and truss structures depends on load distribution, span length, and material efficiency requirements. Cantilever beams are ideal for projects requiring overhanging sections without external support, offering simplicity in design but higher material stress. Truss systems excel in distributing tension and compression forces across interconnected triangles, making them suitable for longer spans and heavy loads with optimized material use.

Cantilever Infographic

libterm.com

libterm.com