Stress concentrators are areas within a material where stress is significantly higher than the surrounding regions, often due to geometric discontinuities like holes, notches, or cracks. These localized stress peaks can lead to material failure if not properly addressed in design or maintenance. Discover how understanding stress concentrators can help you improve structural integrity by exploring the rest of the article.

Table of Comparison

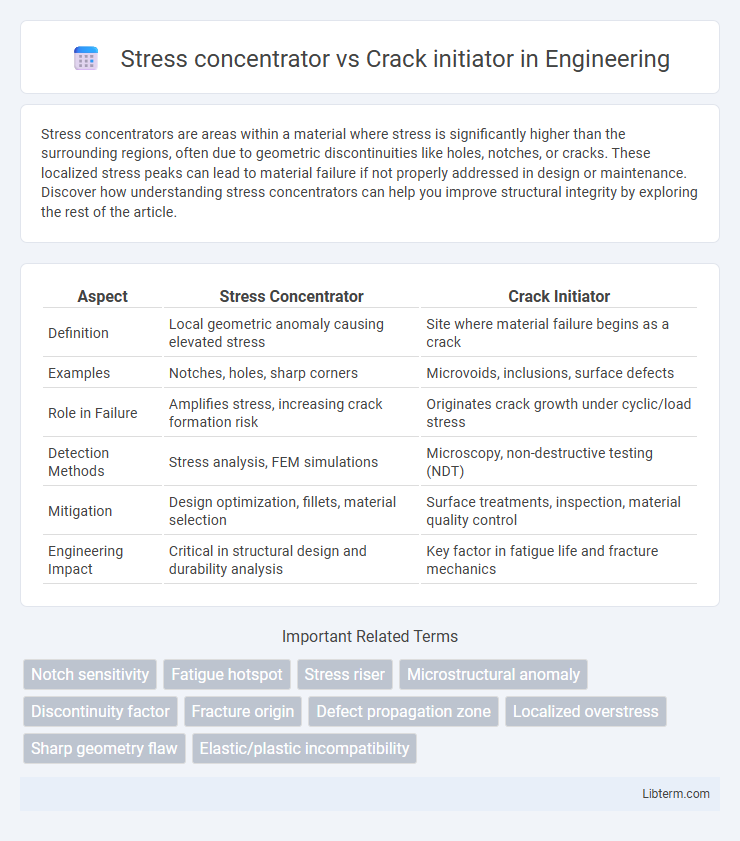

| Aspect | Stress Concentrator | Crack Initiator |

|---|---|---|

| Definition | Local geometric anomaly causing elevated stress | Site where material failure begins as a crack |

| Examples | Notches, holes, sharp corners | Microvoids, inclusions, surface defects |

| Role in Failure | Amplifies stress, increasing crack formation risk | Originates crack growth under cyclic/load stress |

| Detection Methods | Stress analysis, FEM simulations | Microscopy, non-destructive testing (NDT) |

| Mitigation | Design optimization, fillets, material selection | Surface treatments, inspection, material quality control |

| Engineering Impact | Critical in structural design and durability analysis | Key factor in fatigue life and fracture mechanics |

Understanding Stress Concentrators

Stress concentrators are geometric features or material flaws that cause localized increases in stress within a material, often serving as the origin points for crack initiation. Common stress concentrators include notches, holes, sharp corners, and surface scratches, which amplify stress intensity and reduce the overall structural integrity. Understanding the behavior of stress concentrators is crucial for predicting fatigue life and preventing catastrophic failure in engineering components.

Defining Crack Initiators

Crack initiators are microscopic defects or material discontinuities such as inclusions, voids, or surface scratches that serve as the origin points for crack formation under cyclic or static loading. Unlike stress concentrators, which are geometric features like notches or holes that amplify local stress, crack initiators are intrinsic imperfections within the material's microstructure that lead to localized plastic deformation and eventual crack nucleation. Understanding crack initiators is critical for predicting fatigue life and enhancing material durability by controlling manufacturing processes and material quality.

Key Differences Between Stress Concentrators and Crack Initiators

Stress concentrators are geometric features such as notches, holes, or sharp corners that cause localized increases in stress within a material. Crack initiators, often microscopic defects like inclusions, voids, or corrosion pits, serve as the origin points where cracks begin to form under cyclic loading or stress. The key difference lies in their nature: stress concentrators amplify stress but do not always cause cracking, whereas crack initiators are the actual sites where material failure initiates.

Common Examples of Stress Concentrators

Common examples of stress concentrators include sharp corners, notches, holes, and sudden changes in cross-sectional areas that create localized increases in stress. These features disrupt the uniform distribution of stress, leading to elevated stress levels that can act as crack initiators under cyclic or dynamic loading. Understanding the role of these geometric discontinuities is crucial in materials engineering to prevent premature failure.

Origins and Types of Crack Initiators

Stress concentrators, such as notches, sharp corners, and material discontinuities, serve as origins where local stress intensifies, significantly increasing the likelihood of crack initiation. Crack initiators typically arise from microscopic defects like inclusions, voids, grain boundary phases, or surface irregularities, which act as nucleation points under cyclic loading or environmental stress. Understanding the types of crack initiators--including corrosion pits, fatigue striations, and slip bands--helps in predicting fatigue life and improving material design against fracture.

Role in Material Failure

Stress concentrators, such as notches or sharp corners, intensify localized stress in materials, significantly lowering the threshold for crack initiation. Crack initiators emerge from these stress concentrators, where microstructural imperfections or external defects evolve into propagating cracks under cyclic loading. Their combined role accelerates material failure by promoting crack growth that leads to catastrophic fracturing.

Detection and Analysis Techniques

Stress concentrators such as notches or holes create localized increases in stress, detectable using techniques like digital image correlation (DIC) and finite element analysis (FEA) for precise strain mapping. Crack initiators, often microscopic defects or corrosion pits, require advanced methods like scanning electron microscopy (SEM) and acoustic emission testing to identify early-stage crack formation. Combining non-destructive evaluation tools with computational modeling enhances the accuracy of detecting and analyzing both stress concentrators and crack initiators in structural components.

Impact on Structural Integrity

Stress concentrators, such as notches or sharp corners, create localized areas of elevated stress that significantly weaken structural components by promoting the onset of material deformation. Crack initiators originate from these stress concentrators and develop into propagating fractures under cyclic loads or sudden impacts, severely compromising structural integrity. The progression from stress concentrator to crack initiator accelerates failure mechanisms, reducing lifespan and increasing the risk of catastrophic structural collapse.

Material Design Strategies to Minimize Risks

Stress concentrators such as notches or sharp corners create localized regions of high stress that act as potential crack initiators by increasing the likelihood of microvoid formation. Material design strategies to minimize risks include optimizing geometry to avoid abrupt transitions, utilizing composite materials with high fracture toughness, and applying surface treatments like shot peening to induce compressive residual stresses. Incorporating these approaches enhances resistance to crack initiation and propagation, improving the overall durability and lifespan of structural components.

Advances in Monitoring and Prevention Technologies

Stress concentrators are localized areas within materials where stress is significantly amplified, often serving as precursors to crack initiation; advances in monitoring technologies like digital image correlation and acoustic emission sensors have improved early detection of these zones. Crack initiators typically form at these stress concentrators due to material fatigue or defects, and recent prevention technologies such as surface treatments, additive manufacturing with optimized microstructures, and real-time structural health monitoring systems have enhanced material resilience and extended service life. Integration of machine learning algorithms in predictive maintenance enables more accurate identification of critical stress concentrators and crack initiation sites, facilitating timely intervention and reducing failure risks.

Stress concentrator Infographic

libterm.com

libterm.com