Ductility measures a material's ability to undergo significant plastic deformation before rupture, which is essential in structural applications to prevent sudden failure. Materials with high ductility, such as metals like copper and aluminum, can absorb energy and deform under stress without breaking. Discover how understanding ductility can improve your material selection and ensure safety in engineering projects by reading the rest of the article.

Table of Comparison

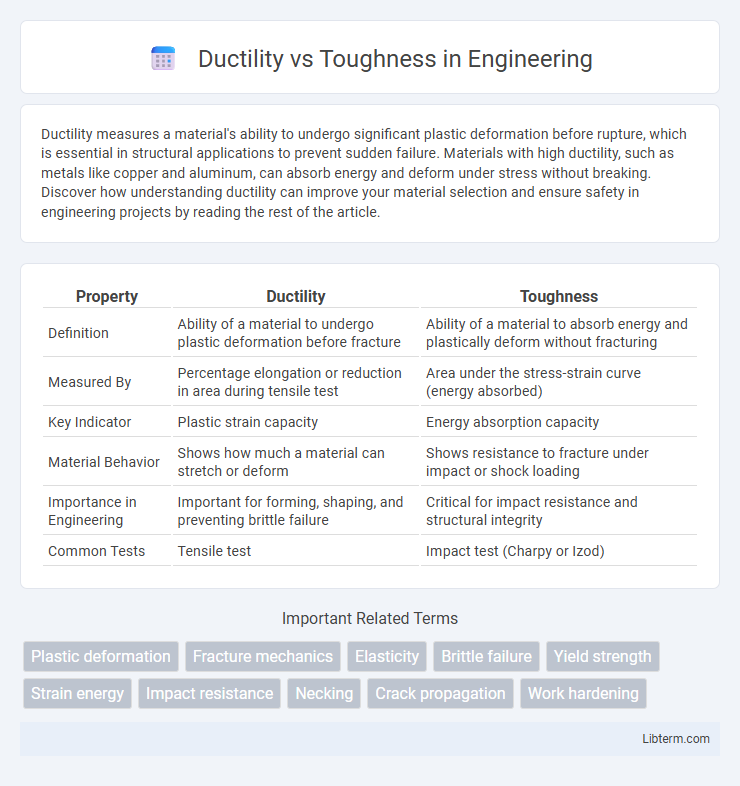

| Property | Ductility | Toughness |

|---|---|---|

| Definition | Ability of a material to undergo plastic deformation before fracture | Ability of a material to absorb energy and plastically deform without fracturing |

| Measured By | Percentage elongation or reduction in area during tensile test | Area under the stress-strain curve (energy absorbed) |

| Key Indicator | Plastic strain capacity | Energy absorption capacity |

| Material Behavior | Shows how much a material can stretch or deform | Shows resistance to fracture under impact or shock loading |

| Importance in Engineering | Important for forming, shaping, and preventing brittle failure | Critical for impact resistance and structural integrity |

| Common Tests | Tensile test | Impact test (Charpy or Izod) |

Understanding Ductility: Definition and Importance

Ductility refers to a material's ability to undergo significant plastic deformation before fracture, allowing it to be stretched into wires or sheets without breaking. It is a critical property in metals such as copper and aluminum, where high ductility ensures flexibility and shapeability during manufacturing processes. Understanding ductility is essential for applications requiring materials that can absorb energy and deform without sudden failure.

Exploring Toughness: What Does It Mean in Materials Science?

Toughness in materials science quantifies a material's ability to absorb energy and plastically deform without fracturing, combining both strength and ductility. It is measured through impact tests like Charpy or Izod, reflecting resistance to crack propagation under sudden loads. Unlike ductility, which indicates how much a material can deform before failure, toughness emphasizes energy absorption capacity, making it crucial for applications requiring impact resistance and durability.

Key Differences: Ductility vs Toughness Explained

Ductility measures a material's ability to undergo significant plastic deformation before fracture, typically indicated by elongation or reduction in area during tensile testing. Toughness quantifies the total energy absorbed by a material up to fracture, reflecting both strength and ductility, often determined by the area under the stress-strain curve or impact tests like Charpy. While ductility emphasizes deformation capacity, toughness represents resistance to fracture under impact or sudden loads, making them distinct but complementary mechanical properties.

Measuring Ductility: Common Tests and Methods

Ductility is commonly measured using tensile tests that determine the material's ability to undergo plastic deformation before fracture, quantified by elongation percentage and reduction in area. Another standard method is the bend test, which evaluates a material's flexibility by measuring its resistance to cracking under bending stress. These tests provide critical data on ductility, distinct from toughness, which encompasses energy absorption and resistance to fracture under impact loading.

Assessing Toughness: How Is It Quantified?

Toughness is quantified through the area under the stress-strain curve obtained from tensile or impact tests, representing a material's ability to absorb energy before fracturing. Charpy and Izod impact tests measure toughness by evaluating energy absorbed during fracture under high strain-rate conditions. Unlike ductility, which only measures deformation before failure, toughness encompasses both strength and ductility, indicating a material's resistance to crack propagation and catastrophic failure.

Factors Influencing Ductility in Materials

Ductility in materials is primarily influenced by factors such as temperature, strain rate, and material composition, where higher temperatures and slower strain rates generally increase ductility. The presence of alloying elements, grain size, and crystal structure also play critical roles in determining a material's ability to undergo plastic deformation without fracturing. Understanding these factors helps in tailoring materials for applications requiring specific deformation behaviors and mechanical performance.

What Affects Material Toughness?

Material toughness is primarily affected by its microstructure, temperature, and strain rate during deformation. Grain size refinement enhances toughness by impeding crack propagation, while higher temperatures generally increase toughness by allowing more plastic deformation before fracture. Strain rate sensitivity also influences toughness, as materials subjected to rapid loading tend to exhibit lower toughness due to limited energy absorption capacity.

Real-World Applications: When to Prioritize Ductility vs Toughness

In construction and automotive industries, ductility is prioritized for materials requiring significant deformation without failure, such as steel used in earthquake-resistant buildings and crash zones in vehicles. Toughness is essential in applications like armor plating and cutting tools, where resistance to impact and fracture is critical. Engineers select ductile materials for flexibility and energy absorption, while tough materials are chosen to withstand sudden forces and prevent catastrophic breakage.

Ductility and Toughness in Engineering Design

Ductility in engineering design refers to a material's ability to undergo significant plastic deformation before fracture, allowing structures to absorb energy and deform without sudden failure. Toughness measures the total energy a material can absorb before fracturing, combining strength and ductility to prevent catastrophic failures in critical components. Engineers prioritize materials with high ductility for applications requiring flexibility and toughness for impact resistance to ensure safety and durability in structural designs.

Summary: Choosing the Right Property for Material Selection

Ductility measures a material's ability to undergo significant plastic deformation before fracture, crucial for applications requiring shaping or bending. Toughness represents the material's capacity to absorb energy and resist fracture under impact, essential for components subjected to dynamic or shock loads. Selecting between ductility and toughness depends on whether the priority is deformability without failure or resistance to sudden fracture during service.

Ductility Infographic

libterm.com

libterm.com