A finger joint, also known as a box joint, is a woodworking technique used to join two pieces of wood at right angles with interlocking rectangular "fingers" that increase surface area for strong adhesion. This joint offers excellent mechanical strength and aesthetic appeal, making it popular in cabinetry, drawers, and furniture construction. Explore the detailed benefits and construction methods of finger joints in the rest of this article.

Table of Comparison

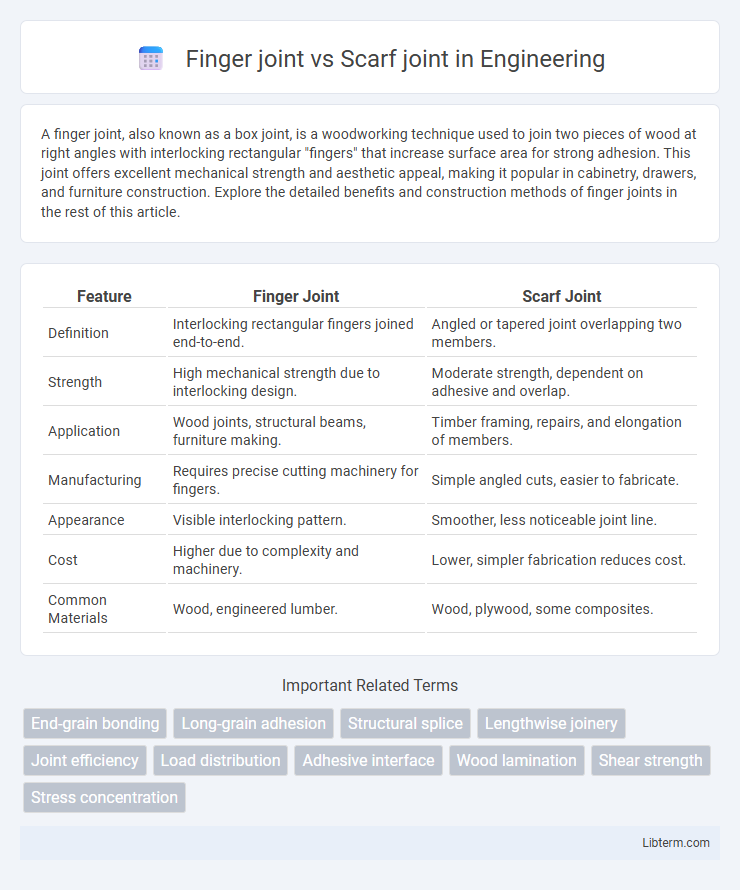

| Feature | Finger Joint | Scarf Joint |

|---|---|---|

| Definition | Interlocking rectangular fingers joined end-to-end. | Angled or tapered joint overlapping two members. |

| Strength | High mechanical strength due to interlocking design. | Moderate strength, dependent on adhesive and overlap. |

| Application | Wood joints, structural beams, furniture making. | Timber framing, repairs, and elongation of members. |

| Manufacturing | Requires precise cutting machinery for fingers. | Simple angled cuts, easier to fabricate. |

| Appearance | Visible interlocking pattern. | Smoother, less noticeable joint line. |

| Cost | Higher due to complexity and machinery. | Lower, simpler fabrication reduces cost. |

| Common Materials | Wood, engineered lumber. | Wood, plywood, some composites. |

Introduction to Finger Joints and Scarf Joints

Finger joints, characterized by interlocking rectangular projections, provide enhanced mechanical strength and increased gluing surface area for wood or metal connections. Scarf joints involve angled cuts that create a long, tapered overlap, maximizing surface contact for adhesive bonding in structural or aesthetic applications. Both joints are essential in woodworking and construction, with finger joints excelling in load-bearing efficiency and scarf joints favored for seamless, elongated joins.

What is a Finger Joint?

A finger joint, also known as a box joint, is a woodworking joint made by cutting a set of complementary, interlocking profiles resembling fingers on the ends of two pieces of wood. This joint provides a large gluing surface area, increasing the bond strength and offering superior resistance to tensile and compressive forces compared to a scarf joint. Commonly used in cabinet making and drawer construction, finger joints enhance structural integrity and aesthetic appeal through precise alignment.

What is a Scarf Joint?

A scarf joint is a woodworking technique used to join two pieces of wood end-to-end by cutting opposing angled surfaces that fit together, creating a longer, continuous piece. This joint provides increased gluing surface area and enhanced structural strength compared to a simple butt joint. Often employed in timber framing and carpentry, scarf joints are ideal for extending beams or repairing damaged sections while maintaining alignment and load-bearing capacity.

Structural Strength Comparison

Finger joints provide superior structural strength compared to scarf joints due to their increased gluing surface area and interlocking design, which distributes stress more evenly across the joint. Scarf joints rely primarily on adhesive strength and precise cutting angles, making them less resistant to tensile and shear forces. In applications requiring high load-bearing capacity and durability, finger joints are preferred for their enhanced mechanical stability and resistance to joint separation.

Aesthetic and Visual Differences

Finger joints exhibit a distinctive interlocking pattern that creates a visually appealing zigzag effect, enhancing the complexity and craftsmanship of woodworking joints. Scarf joints present a smoother, elongated seam designed to blend seamlessly with the grain, offering a more subtle and continuous visual appearance ideal for applications requiring minimal joint visibility. The aesthetic choice between finger and scarf joints depends on whether the design prioritizes decorative contrast or a unified, inconspicuous finish.

Applications in Woodworking and Construction

Finger joints offer superior strength and stability, making them ideal for creating long, straight assemblies like furniture panels, door components, and cabinetry where load-bearing capacity is crucial. Scarf joints are preferred in applications requiring angled repairs or extensions of timber, such as rafters, beams, and moldings, where seamless appearance and lengthening of wood elements are essential. Both joints enhance material efficiency in woodworking and construction, with finger joints excelling in precision and load distribution, while scarf joints provide flexibility in joining wood at various angles.

Ease of Fabrication and Assembly

Finger joints offer easier fabrication due to their repetitive interlocking fingers that can be cut precisely with CNC machines or routers, ensuring consistent alignment and strength. Scarf joints require more precise angled cuts and careful fitting to achieve a seamless connection, making assembly more challenging and time-consuming. The simplicity of finger joints reduces assembly errors and labor costs, while scarf joints demand skilled craftsmanship for optimal results.

Durability and Longevity

Finger joints provide superior durability and longevity due to their large gluing surface area, which ensures a strong mechanical bond that resists stress and wear over time. Scarf joints, while offering a smooth, continuous appearance, generally have less gluing surface area, making them more susceptible to failure under heavy loads or moisture exposure. In woodworking and construction, finger joints are preferred for applications requiring enhanced strength and long-lasting performance.

Cost and Material Efficiency

Finger joints offer superior material efficiency by utilizing smaller, interlocking fingers that minimize waste and maximize wood usage, making them cost-effective for mass production. Scarf joints require more precise cuts and longer lengths of material, often increasing both labor and material costs due to more significant wood removal. Manufacturers favor finger joints for their balance of strength, reduced material waste, and lower overall production expenses compared to scarf joints.

Choosing the Right Joint for Your Project

When choosing between a finger joint and a scarf joint, consider the load-bearing capacity and precision requirements of your project. Finger joints provide superior strength and alignment for connecting wood at right angles, making them ideal for box-like structures and furniture. Scarf joints are better suited for lengthening timber with a smooth, tapered repair that maintains aesthetic continuity while requiring moderate structural strength.

Finger joint Infographic

libterm.com

libterm.com