Opposed-piston engines offer enhanced thermal efficiency by eliminating the cylinder head and reducing heat loss. This design results in improved power density and lower emissions compared to traditional engines. Discover how this innovative technology can transform your understanding of engine performance in the full article.

Table of Comparison

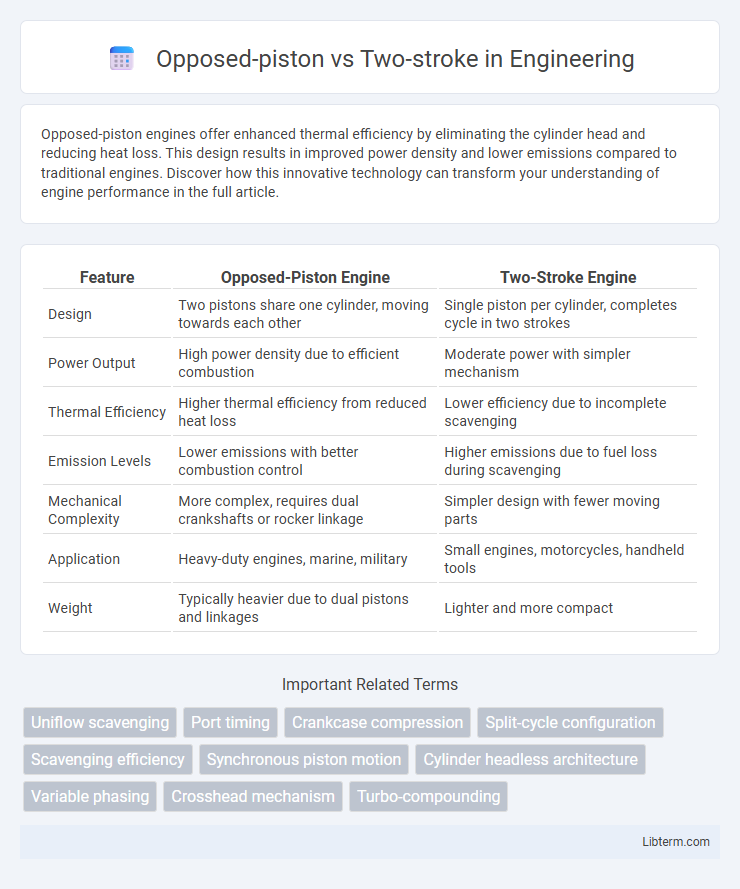

| Feature | Opposed-Piston Engine | Two-Stroke Engine |

|---|---|---|

| Design | Two pistons share one cylinder, moving towards each other | Single piston per cylinder, completes cycle in two strokes |

| Power Output | High power density due to efficient combustion | Moderate power with simpler mechanism |

| Thermal Efficiency | Higher thermal efficiency from reduced heat loss | Lower efficiency due to incomplete scavenging |

| Emission Levels | Lower emissions with better combustion control | Higher emissions due to fuel loss during scavenging |

| Mechanical Complexity | More complex, requires dual crankshafts or rocker linkage | Simpler design with fewer moving parts |

| Application | Heavy-duty engines, marine, military | Small engines, motorcycles, handheld tools |

| Weight | Typically heavier due to dual pistons and linkages | Lighter and more compact |

Introduction to Opposed-Piston and Two-Stroke Engines

Opposed-piston engines feature two pistons sharing a single cylinder, moving toward each other to compress and ignite fuel, maximizing efficiency and reducing weight. Two-stroke engines complete a power cycle in just two strokes of the piston, allowing for a higher power-to-weight ratio and simpler construction compared to four-stroke engines. Both engine types are valued for their compact design and power density in applications such as motorcycles, marine vessels, and small aircraft.

Historical Development and Applications

Opposed-piston engines, dating back to the early 20th century, offered enhanced thermal efficiency by eliminating cylinder heads, significantly impacting military and marine applications during World War II. Two-stroke engines, widely developed throughout the 19th and 20th centuries, gained popularity in lightweight power tools, motorcycles, and outboard motors due to their simplified valve mechanism and high power-to-weight ratio. Innovations in opposed-piston designs have driven recent interest in heavy-duty and commercial vehicle markets, while two-stroke engines remain dominant in small-scale, high-speed applications.

Core Design Differences

Opposed-piston engines feature two pistons moving in opposite directions within a single cylinder, eliminating the need for cylinder heads and enabling efficient combustion and reduced heat loss. Two-stroke engines rely on a single piston and use ports in the cylinder walls for intake and exhaust, simplifying valve mechanisms but often causing less precise gas exchange control. The core design difference lies in the opposed-piston's dual-piston setup for improved thermal efficiency versus the two-stroke's single-piston with port-based scavenging system.

Combustion Process Comparison

Opposed-piston engines feature two pistons within a single cylinder moving towards each other, enabling more efficient scavenging and minimizing unburned fuel during the two-stroke combustion process. Traditional two-stroke engines rely on ports and valves controlled by a single piston, often resulting in less complete combustion and higher emissions. The opposed-piston design enhances combustion chamber geometry, improving thermal efficiency and reducing fuel consumption in comparison to conventional two-stroke engines.

Efficiency and Power Output

Opposed-piston engines exhibit higher thermal efficiency compared to conventional two-stroke designs by eliminating the cylinder head and reducing heat loss, resulting in improved fuel economy and lower emissions. These engines achieve superior power density due to the balanced combustion chambers on both pistons, which enable more complete combustion and increased power output per displacement. Two-stroke engines generally offer higher power-to-weight ratios but suffer from lower efficiency and higher pollutant emissions due to incomplete scavenging and fuel loss during the exhaust process.

Emissions and Environmental Impact

Opposed-piston engines typically produce lower NOx and particulate emissions compared to traditional two-stroke engines due to their improved combustion efficiency and reduced surface area for heat loss. Advanced opposed-piston designs enable more complete fuel burning, resulting in decreased unburned hydrocarbons and carbon monoxide emissions, contributing to a smaller environmental footprint. In contrast, conventional two-stroke engines often suffer from higher pollution levels caused by fuel scavenging losses and incomplete combustion, leading to increased smog and greenhouse gas formation.

Maintenance and Longevity

Opposed-piston engines feature fewer moving parts and balanced forces, resulting in reduced wear and simpler maintenance compared to conventional two-stroke engines with separate pistons and more complex valve systems. The design inherently improves sealing and thermal efficiency, enhancing engine longevity by minimizing typical two-stroke issues such as excessive oil consumption and overheating. Maintenance intervals in opposed-piston engines often extend further due to these efficiencies, contributing to lower operational downtime and cost over the engine's lifespan.

Industrial and Automotive Usage

Opposed-piston engines offer higher thermal efficiency and lower emissions compared to conventional two-stroke engines, making them increasingly attractive for heavy-duty industrial applications and some automotive sectors seeking improved fuel economy. Two-stroke engines dominate lightweight and small-scale automotive markets due to their simpler design and higher power-to-weight ratio, despite typically higher emissions and lower fuel efficiency. Industrial use of opposed-piston designs spans marine propulsion, power generation, and commercial vehicles where durability and emission standards are critical, whereas two-stroke engines remain preferred in motorcycles, lawn equipment, and small off-road vehicles.

Future Trends and Technological Innovations

Opposed-piston engines are gaining traction in the future of two-stroke technology due to their improved thermal efficiency and reduced emissions compared to traditional port-scavenged designs. Innovations such as advanced fuel injection systems, variable valve timing, and hybrid-electric integrations are enhancing performance and adaptability in commercial and marine applications. Growing environmental regulations and the push for carbon neutrality drive ongoing research into lightweight materials and alternative fuels for both opposed-piston and conventional two-stroke engines.

Summary: Choosing the Right Engine Type

Opposed-piston engines deliver higher thermal efficiency and reduced emissions compared to traditional two-stroke engines, making them suitable for applications requiring fuel economy and lower environmental impact. Two-stroke engines offer simpler design and lighter weight, favored in smaller, high-power-to-weight ratio machinery and motorcycles. Selecting between opposed-piston and two-stroke engines depends on priorities like efficiency, emissions, complexity, and intended application.

Opposed-piston Infographic

libterm.com

libterm.com