Fillet welds are a common type of weld used to join two surfaces at a right angle, providing strength and stability in metal structures. Understanding the proper techniques and applications for fillet welds is essential to ensure the integrity of your projects. Explore the rest of the article to learn how to achieve strong, reliable fillet welds for your fabrication needs.

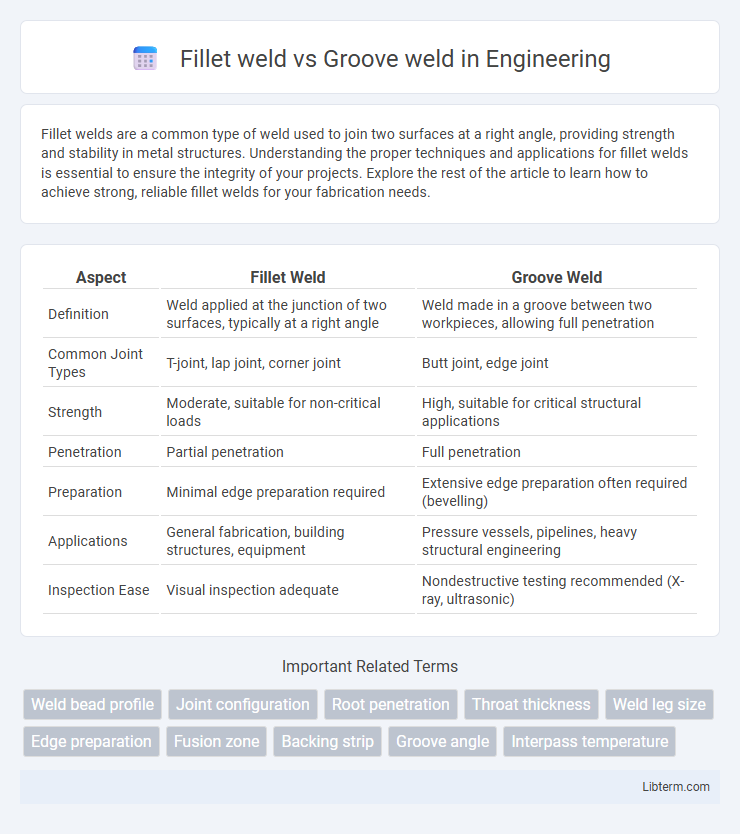

Table of Comparison

| Aspect | Fillet Weld | Groove Weld |

|---|---|---|

| Definition | Weld applied at the junction of two surfaces, typically at a right angle | Weld made in a groove between two workpieces, allowing full penetration |

| Common Joint Types | T-joint, lap joint, corner joint | Butt joint, edge joint |

| Strength | Moderate, suitable for non-critical loads | High, suitable for critical structural applications |

| Penetration | Partial penetration | Full penetration |

| Preparation | Minimal edge preparation required | Extensive edge preparation often required (bevelling) |

| Applications | General fabrication, building structures, equipment | Pressure vessels, pipelines, heavy structural engineering |

| Inspection Ease | Visual inspection adequate | Nondestructive testing recommended (X-ray, ultrasonic) |

Introduction to Fillet Welds and Groove Welds

Fillet welds join two surfaces at an approximate right angle, commonly used in lap, T, and corner joints, providing moderate strength with a triangular cross-section. Groove welds are made in the groove between two aligned workpieces, designed to create full-penetration joints essential for high-strength applications. Understanding the geometric differences and load requirements is crucial for selecting between fillet and groove welds in structural and fabrication projects.

Definition and Characteristics of Fillet Welds

Fillet welds are a type of weld used to join two surfaces at approximately right angles, commonly found in lap, T, and corner joints, characterized by their triangular cross-section. They do not require edge preparation and can be applied on flat, horizontal, or vertical surfaces, making them versatile and efficient for general fabrication. Fillet welds provide moderate strength and are easier and faster to execute compared to groove welds, which involve joining the edges of two pieces with edge preparation for deeper penetration.

Definition and Characteristics of Groove Welds

Groove welds join two pieces of metal along a beveled edge or groove, providing deeper penetration and stronger joints compared to fillet welds. They are characterized by their preparation, including V-groove, U-groove, J-groove, or square groove shapes, allowing better access for welding and improved fusion between the base metals. Groove welds are commonly used in applications requiring high strength and structural integrity, such as pressure vessels, pipelines, and heavy machinery.

Key Differences Between Fillet and Groove Welds

Fillet welds join two surfaces at an approximate right angle, typically used in lap, T, or corner joints, while groove welds involve welding within the joint's groove, providing full penetration in butt joints. Fillet welds are usually triangular in cross-section and do not require edge preparation, whereas groove welds necessitate precise edge shaping for deeper weld penetration and strength. Groove welds offer higher strength and are preferred for critical structural applications, whereas fillet welds are simpler and faster for less demanding tasks.

Advantages of Fillet Welds

Fillet welds offer significant advantages including faster application due to simpler preparation and alignment, making them ideal for joining perpendicular or lap joints. They require less edge preparation compared to groove welds, reducing labor costs and increasing efficiency in production settings. Their versatility in accommodating different joint configurations enhances structural integrity while minimizing welding defects.

Advantages of Groove Welds

Groove welds offer superior strength and deep penetration, making them ideal for critical structural applications. They provide better access for quality inspection and reduce the risk of defects compared to fillet welds. This weld type ensures a stronger joint in thick materials and high-stress environments.

Common Applications for Fillet Welds

Fillet welds are commonly used in structural steel fabrication, such as connecting beams, columns, and reinforcing plates, due to their efficiency in joining perpendicular or angled metal surfaces. They are prevalent in shipbuilding, automotive frames, and bridge construction where quick, strong welds are essential for load-bearing joints. Fillet welds provide reliable strength without the need for edge preparation, making them ideal for T-joints, lap joints, and corner joints in various industrial applications.

Common Applications for Groove Welds

Groove welds are commonly used in structural steel fabrication, pipeline construction, and heavy machinery assembly due to their ability to join thick materials with full penetration. They provide strong, continuous welds ideal for load-bearing joints and pressure vessels where strength and integrity are critical. Groove welds are preferred in situations requiring precise alignment and high fatigue resistance, such as bridges, shipbuilding, and automotive frames.

Selection Criteria: Fillet Weld vs Groove Weld

Fillet welds are ideal for joining perpendicular or lap joints with moderate strength requirements, offering faster application and lower cost compared to groove welds. Groove welds are preferred for high-strength structural connections requiring full penetration and thorough fusion, especially in thick materials or critical load-bearing applications. Selection between fillet and groove weld depends on factors such as joint design, material thickness, required weld strength, inspection standards, and fabrication efficiency.

Conclusion: Choosing the Right Weld for Your Project

Fillet welds provide strong, versatile joints ideal for lap, T, and corner connections with less preparation, making them suitable for quick assembly and lower-stress applications. Groove welds offer deeper penetration and superior strength, essential for thick materials and critical structural components requiring full joint penetration and rigorous load-bearing capacity. Selecting the right weld depends on material thickness, joint design, load requirements, and industry standards like AWS D1.1 to ensure weld integrity and project success.

Fillet weld Infographic

libterm.com

libterm.com