Parallel-flow systems enhance thermal efficiency by allowing multiple fluid streams to move simultaneously in the same direction, minimizing temperature gradients and pressure drops. This design is commonly used in heat exchangers and cooling applications where uniform temperature distribution is critical. Explore the rest of the article to understand how parallel-flow can improve your system's performance.

Table of Comparison

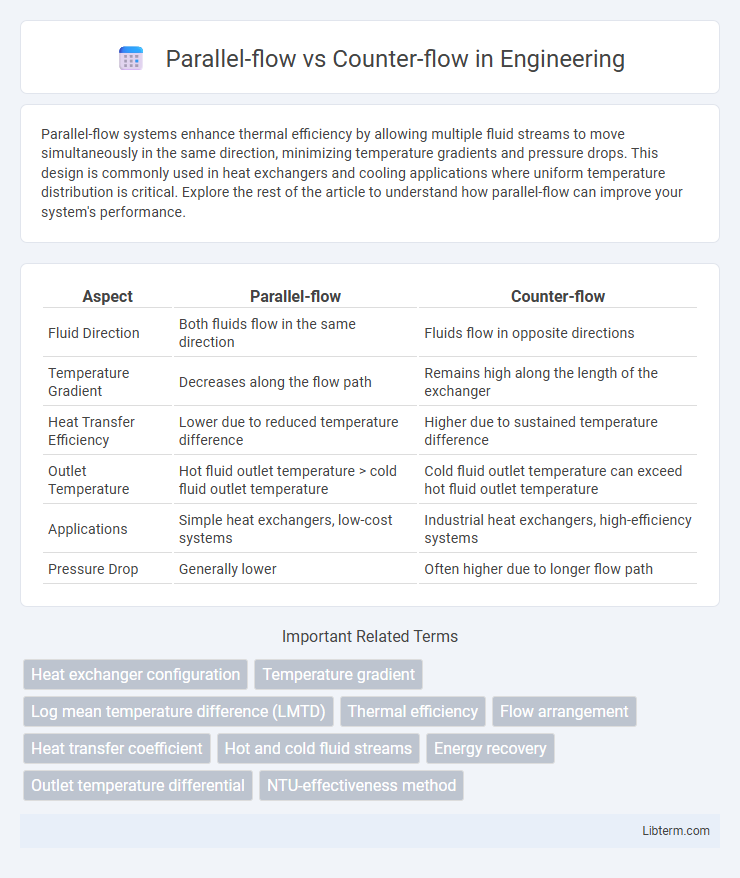

| Aspect | Parallel-flow | Counter-flow |

|---|---|---|

| Fluid Direction | Both fluids flow in the same direction | Fluids flow in opposite directions |

| Temperature Gradient | Decreases along the flow path | Remains high along the length of the exchanger |

| Heat Transfer Efficiency | Lower due to reduced temperature difference | Higher due to sustained temperature difference |

| Outlet Temperature | Hot fluid outlet temperature > cold fluid outlet temperature | Cold fluid outlet temperature can exceed hot fluid outlet temperature |

| Applications | Simple heat exchangers, low-cost systems | Industrial heat exchangers, high-efficiency systems |

| Pressure Drop | Generally lower | Often higher due to longer flow path |

Introduction to Flow Configurations

Parallel-flow and counter-flow represent two fundamental heat exchanger flow configurations that significantly impact heat transfer efficiency. In parallel-flow, both fluids move in the same direction, resulting in a rapid temperature approach but lower overall heat transfer compared to counter-flow. Counter-flow maximizes temperature gradient by having fluids flow in opposite directions, enhancing thermal performance and enabling closer outlet temperatures.

Defining Parallel-flow Systems

Parallel-flow systems involve both the hot and cold fluids entering the heat exchanger at the same end and moving in the same direction. This configuration allows for a rapid initial temperature change but results in a lower overall heat transfer efficiency compared to counter-flow systems. Parallel-flow heat exchangers are typically used in applications requiring quick temperature equalization within a compact space.

Defining Counter-flow Systems

Counter-flow systems are characterized by the opposite direction of fluid flow between the hot and cold streams, maximizing heat transfer efficiency by maintaining a larger temperature gradient throughout the exchanger. This design allows continuous heat exchange with minimal energy loss, making it ideal for applications in HVAC, refrigeration, and industrial processes. Compared to parallel-flow systems, counter-flow configurations achieve higher thermal performance and improved energy conservation.

Key Differences Between Parallel-flow and Counter-flow

Parallel-flow heat exchangers have both fluids entering the exchanger at the same end and moving in the same direction, resulting in a limited temperature gradient and lower efficiency. Counter-flow heat exchangers feature fluids entering from opposite ends and flowing in opposite directions, which maximizes the temperature difference and enhances heat transfer performance. The key differences lie in temperature profiles, heat transfer efficiency, and thermal effectiveness, with counter-flow designs generally providing superior thermal performance and greater temperature output ranges.

Heat Transfer Efficiency Comparison

Counter-flow heat exchangers typically achieve higher heat transfer efficiency than parallel-flow configurations due to the maintained temperature gradient along the entire exchanger length, enhancing thermal driving force. In counter-flow designs, the hot fluid exits near the entrance of the cold fluid, allowing maximum heat transfer by keeping temperature differences more consistent. Parallel-flow arrangements, where fluids move in the same direction, exhibit a rapidly decreasing temperature gradient, resulting in lower overall heat transfer coefficients and reduced thermal performance.

Temperature Gradient Analysis

In parallel-flow heat exchangers, the temperature gradient between the hot and cold fluids decreases continuously along the flow path, leading to less efficient heat transfer. Counter-flow configurations maintain a higher and more uniform temperature gradient by allowing fluids to flow in opposite directions, maximizing thermal energy exchange. This sustained gradient improves overall heat transfer coefficient and effectiveness compared to parallel-flow systems.

Typical Applications of Parallel-flow

Parallel-flow heat exchangers are commonly used in applications requiring rapid temperature equalization between fluids, such as in automotive radiators and condensers, where both fluids enter the exchanger from the same end. This configuration suits processes with limited temperature differentials and lower heat transfer efficiency but simplifies design and reduces pressure losses. Typical industries include HVAC systems and chemical processing where moderate heat exchange and compact equipment are prioritized.

Typical Applications of Counter-flow

Counter-flow heat exchangers are widely used in applications requiring efficient heat transfer, such as chemical processing, refrigeration, and power plants. Their design maximizes temperature gradients, improving energy recovery in condenser and evaporator units. Industries benefit from counter-flow configurations for effective thermal management in oil refining, HVAC systems, and waste heat recovery processes.

Advantages and Disadvantages of Each Configuration

Parallel-flow heat exchangers offer simpler design and lower initial cost, with both fluids entering the exchanger at the same end and flowing in the same direction, leading to a quicker temperature equilibrium but lower overall heat transfer efficiency. Counter-flow configurations enhance heat transfer efficiency by allowing fluids to flow in opposite directions, maintaining a higher temperature gradient across the exchanger length but often resulting in more complex and costly designs. While parallel-flow systems are easier to clean and maintain, counter-flow systems typically achieve closer approach temperatures, making them more effective for applications requiring significant heat recovery.

Choosing the Optimal Flow Arrangement

Choosing the optimal flow arrangement between parallel-flow and counter-flow heat exchangers depends on maximizing temperature gradients and heat transfer efficiency. Counter-flow configurations often provide higher thermal performance by maintaining a greater average temperature difference throughout the exchanger, resulting in improved energy transfer. Parallel-flow setups may be preferred for simpler design and lower cost but generally yield lower heat recovery compared to the counter-flow option.

Parallel-flow Infographic

libterm.com

libterm.com