Electron beam melting (EBM) is an advanced additive manufacturing technique that uses a focused electron beam to melt metal powder layer by layer, creating highly precise and complex parts. This process is known for producing components with excellent mechanical properties and minimal residual stress, making it ideal for aerospace, medical implants, and automotive industries. Discover how EBM can revolutionize your manufacturing processes by exploring the full details in this article.

Table of Comparison

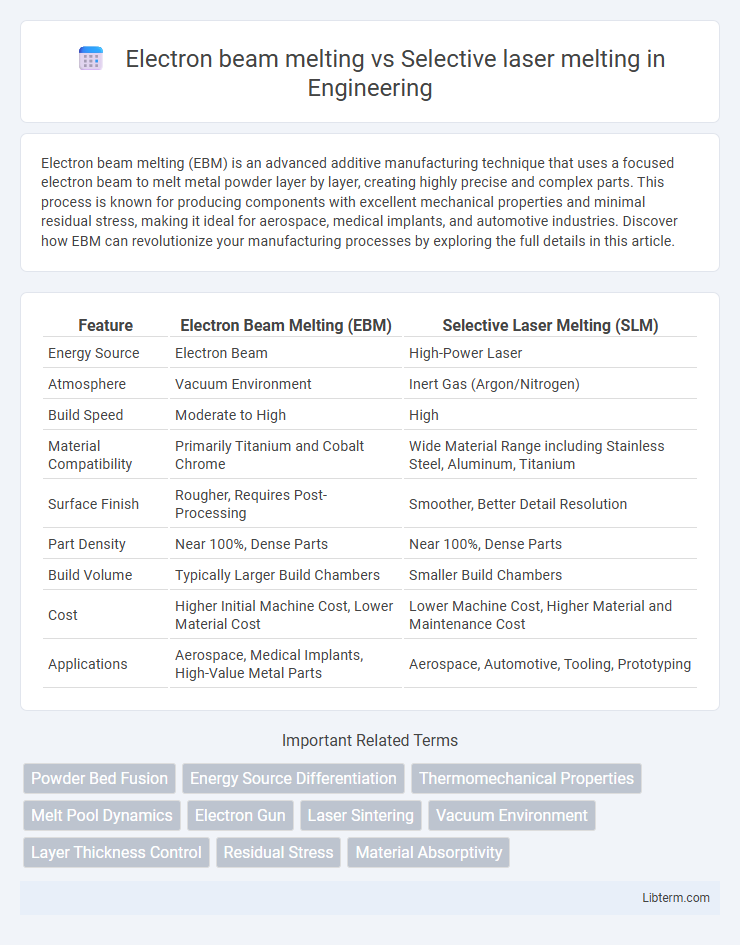

| Feature | Electron Beam Melting (EBM) | Selective Laser Melting (SLM) |

|---|---|---|

| Energy Source | Electron Beam | High-Power Laser |

| Atmosphere | Vacuum Environment | Inert Gas (Argon/Nitrogen) |

| Build Speed | Moderate to High | High |

| Material Compatibility | Primarily Titanium and Cobalt Chrome | Wide Material Range including Stainless Steel, Aluminum, Titanium |

| Surface Finish | Rougher, Requires Post-Processing | Smoother, Better Detail Resolution |

| Part Density | Near 100%, Dense Parts | Near 100%, Dense Parts |

| Build Volume | Typically Larger Build Chambers | Smaller Build Chambers |

| Cost | Higher Initial Machine Cost, Lower Material Cost | Lower Machine Cost, Higher Material and Maintenance Cost |

| Applications | Aerospace, Medical Implants, High-Value Metal Parts | Aerospace, Automotive, Tooling, Prototyping |

Introduction to Electron Beam Melting and Selective Laser Melting

Electron Beam Melting (EBM) and Selective Laser Melting (SLM) are advanced additive manufacturing technologies that create metal parts layer-by-layer using high-energy beams. EBM utilizes a focused electron beam under vacuum conditions to selectively melt metal powder, offering advantages in processing titanium alloys and complex geometries with reduced residual stress. SLM employs a high-powered laser to precisely fuse metal powder in an oxygen-controlled environment, enabling finer resolution and versatility across a broad range of metal materials such as stainless steel, aluminum, and cobalt-chrome.

Fundamental Working Principles

Electron beam melting (EBM) utilizes a focused electron beam to selectively melt metal powder in a vacuum environment, achieving high energy density and rapid melting rates ideal for reactive materials. Selective laser melting (SLM) employs a high-power laser to fuse metal powder layer by layer in an inert gas atmosphere, providing precise control over melt pool and fine feature resolution. Both additive manufacturing techniques rely on layer-wise powder fusion but differ in energy source, environmental conditions, and material compatibility.

Key Differences in Energy Sources

Electron beam melting (EBM) uses a focused electron beam as its energy source, operating in a vacuum environment to achieve high energy density and deeper penetration for melting metal powders. Selective laser melting (SLM) employs a high-powered laser beam, typically fiber or CO2 laser, in an inert gas atmosphere to selectively fuse powder particles layer-by-layer with precise control. The vacuum setting in EBM reduces oxidation and allows faster build rates, while SLM's laser enables finer detail and smoother surface finishes due to its smaller spot size and scanning capabilities.

Material Compatibility and Applications

Electron Beam Melting (EBM) excels in processing reactive metals like titanium and cobalt-chrome alloys due to its high vacuum environment, minimizing oxidation and contamination. Selective Laser Melting (SLM) offers broader material compatibility, including stainless steel, aluminum, and high-performance alloys, achieved through its versatile laser technology. EBM's strength lies in aerospace and medical implants where fatigue resistance and biocompatibility are critical, while SLM is favored in automotive and tooling industries for its finer detail resolution and faster production cycles.

Build Speed and Productivity Comparison

Electron beam melting (EBM) generally offers faster build speeds compared to selective laser melting (SLM) due to its higher power density and better energy efficiency, enabling quicker layer melting and thicker layer deposition. Productivity in EBM is enhanced by its ability to operate in a vacuum environment, reducing oxidation and allowing continuous build processes without interruption. SLM provides finer resolution and surface finish but often requires longer build times and post-processing, impacting overall productivity relative to EBM.

Precision, Detail, and Surface Finish

Electron beam melting (EBM) offers high precision with its focused electron beam, enabling intricate geometries and dense parts, but typically results in a rougher surface finish due to the higher energy input and vacuum environment. Selective laser melting (SLM) provides superior detail resolution and finer surface finishes, driven by its smaller laser spot size and controlled powder melting process. Surface roughness in SLM parts generally measures lower (Ra values between 5-15 um) compared to EBM (Ra values often exceeding 15 um), making SLM more suitable for applications demanding tight tolerances and intricate features.

Powder Bed Requirements and Management

Electron Beam Melting (EBM) requires coarser and more conductive metal powders with larger particle sizes, typically in the range of 45-150 microns, to ensure efficient electron beam interaction and minimize charging effects. Selective Laser Melting (SLM) demands finer powder particles, usually 15-45 microns, with high flowability and narrow size distribution to achieve precise layer deposition and high surface quality. Powder bed management in EBM involves maintaining a vacuum environment to prevent oxidation and ensure stable electron beam functioning, whereas SLM operates in an inert gas atmosphere requiring strict control of oxygen levels to avoid powder degradation and ensure part integrity.

Cost Analysis and Economic Considerations

Electron beam melting (EBM) generally incurs higher initial investment costs compared to selective laser melting (SLM) due to the complexity of vacuum systems and electron beam technology. Operational costs for EBM can be lower in terms of energy consumption and material efficiency, but SLM offers faster build speeds, leading to reduced labor costs and higher throughput. Economic considerations favor SLM in industries requiring high precision and surface finish, while EBM is cost-effective for larger, less detailed parts in aerospace and medical implants.

Industrial Adoption and Case Studies

Electron beam melting (EBM) is widely adopted in aerospace and medical industries due to its capability to process high-temperature alloys like titanium with minimal residual stress, demonstrated by its use in manufacturing aerospace turbine blades and orthopedic implants. Selective laser melting (SLM) is preferred for complex geometries and fine detail in industrial applications such as automotive prototyping and tooling, with notable case studies in producing lightweight, high-strength components for Formula 1 racing teams. Both technologies drive industrial innovation but differ in material compatibility, build environment, and post-processing requirements influencing their specific adoption scenarios.

Future Trends and Technological Advancements

Electron beam melting (EBM) and selective laser melting (SLM) are advancing rapidly, with future trends emphasizing increased precision, faster build speeds, and improved material properties through AI-driven process optimization and real-time monitoring systems. Emerging technologies such as multi-beam processing and hybrid manufacturing are expected to enhance the scalability and cost-efficiency of both EBM and SLM, expanding their applications in aerospace, medical implants, and automotive industries. Continued development in powder recycling methods and advanced thermal management aims to reduce defects and energy consumption, positioning both techniques at the forefront of sustainable additive manufacturing solutions.

Electron beam melting Infographic

libterm.com

libterm.com