Fluid film bearings provide smooth, low-friction support by maintaining a thin layer of lubricant between moving surfaces, preventing metal-to-metal contact. These bearings excel in high-speed and heavy-load applications due to their ability to distribute pressure evenly and reduce wear. Discover how fluid film bearings can enhance your machinery's performance in the rest of this article.

Table of Comparison

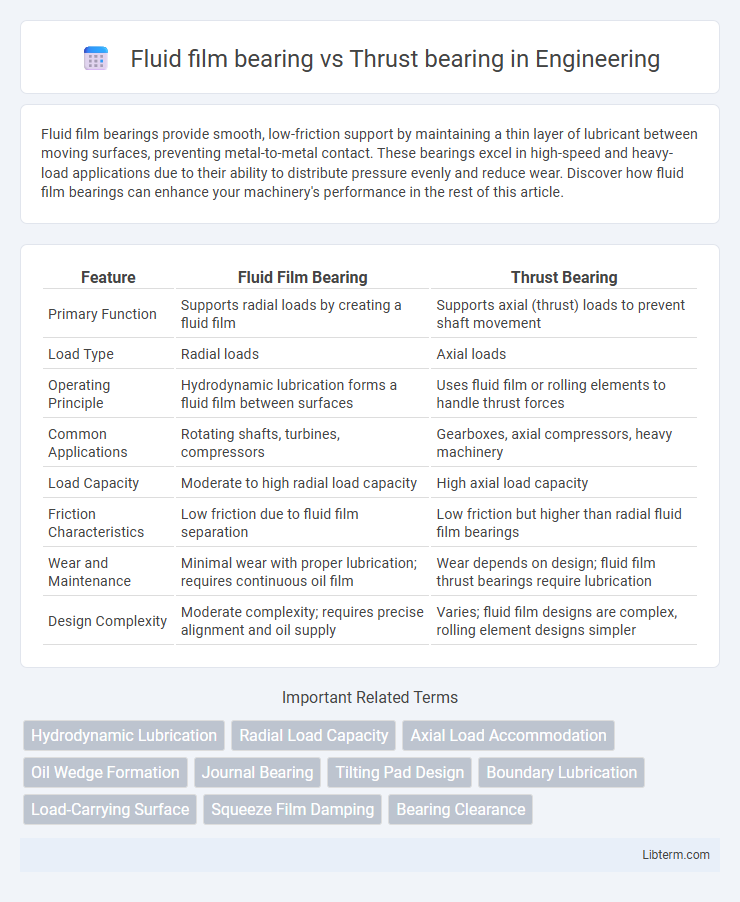

| Feature | Fluid Film Bearing | Thrust Bearing |

|---|---|---|

| Primary Function | Supports radial loads by creating a fluid film | Supports axial (thrust) loads to prevent shaft movement |

| Load Type | Radial loads | Axial loads |

| Operating Principle | Hydrodynamic lubrication forms a fluid film between surfaces | Uses fluid film or rolling elements to handle thrust forces |

| Common Applications | Rotating shafts, turbines, compressors | Gearboxes, axial compressors, heavy machinery |

| Load Capacity | Moderate to high radial load capacity | High axial load capacity |

| Friction Characteristics | Low friction due to fluid film separation | Low friction but higher than radial fluid film bearings |

| Wear and Maintenance | Minimal wear with proper lubrication; requires continuous oil film | Wear depends on design; fluid film thrust bearings require lubrication |

| Design Complexity | Moderate complexity; requires precise alignment and oil supply | Varies; fluid film designs are complex, rolling element designs simpler |

Introduction to Fluid Film Bearings and Thrust Bearings

Fluid film bearings utilize a thin layer of lubricant to support radial loads by creating a hydrodynamic film that separates the moving surfaces, reducing friction and wear. Thrust bearings are specifically designed to handle axial loads, employing rolling elements or fluid film to maintain shaft position under axial stress. Both types are critical in mechanical systems for enhancing load capacity, minimizing friction, and extending machinery lifespan.

Fundamental Principles of Fluid Film Bearings

Fluid film bearings operate on the principle of a thin lubricating film that separates moving surfaces, creating a pressure distribution to support loads and reduce friction. These bearings rely on hydrodynamic lubrication where the relative motion of surfaces generates a fluid film sufficient to prevent direct metal-to-metal contact. In contrast, thrust bearings are designed primarily to withstand axial loads, often incorporating fluid films but sometimes utilizing rolling elements or other mechanisms for load support.

Key Functions of Thrust Bearings

Thrust bearings are designed primarily to handle axial loads, providing support to rotating shafts by absorbing and distributing the force that acts parallel to the shaft axis. These bearings maintain the position of the shaft in various machinery, preventing axial displacement and ensuring smooth operation under axial stress. Fluid film bearings use a thin layer of lubricant to minimize direct metal-to-metal contact, but thrust bearings specifically excel in managing axial forces in applications such as automotive transmissions and turbines.

Design Differences: Fluid Film vs Thrust Bearings

Fluid film bearings utilize a thin layer of lubricating fluid to support radial loads, featuring a simple design with a journal rotating inside a stationary sleeve. Thrust bearings are specifically designed to handle axial loads, often incorporating multiple stacked collars or pads arranged to distribute pressure evenly along the shaft's axis. Key design differences arise from their load orientation, with fluid film bearings optimizing hydrodynamic lubrication for radial motion and thrust bearings engineered to manage directional thrust forces effectively.

Load Capacity Comparison

Fluid film bearings exhibit higher load capacity than thrust bearings due to the hydrodynamic pressure generated within the lubricating film, which supports heavier axial and radial loads in rotating machinery. Thrust bearings primarily handle axial loads and have limited load capacity compared to fluid film bearings, which distribute forces over a larger surface area, reducing wear and improving durability. Industrial applications favor fluid film bearings where high load capacity and reliability under continuous operation are critical.

Efficiency and Friction Analysis

Fluid film bearings exhibit superior efficiency compared to thrust bearings due to their hydrodynamic lubrication, which forms a continuous fluid layer minimizing direct surface contact and significantly reducing friction. Thrust bearings, designed to handle axial loads through direct surface contact, generate higher friction and wear under heavy loads, leading to lower overall efficiency in comparison to fluid film bearings. The reduced friction in fluid film bearings translates to enhanced energy efficiency and longer operational life, making them preferable in high-speed, low-load applications where minimizing energy loss is critical.

Applications in Industry

Fluid film bearings are widely used in high-speed rotating machinery such as turbines, compressors, and pumps due to their ability to support heavy radial loads with minimal friction and wear. Thrust bearings are essential in applications requiring axial load support, including automotive clutch systems, marine propulsion, and heavy-duty gearboxes. Industrial sectors benefit from fluid film bearings in power generation and manufacturing equipment, while thrust bearings are critical in aerospace and construction machinery for maintaining axial stability under heavy loads.

Maintenance and Durability Considerations

Fluid film bearings require precise lubrication system maintenance to sustain the hydrodynamic oil film that minimizes wear and extends operational life, while contamination or oil breakdown significantly reduces durability. Thrust bearings often experience higher axial loads, demanding routine inspection for surface wear, lubrication quality, and potential metal fatigue to prevent failure. Both bearing types benefit from condition monitoring technologies such as vibration analysis and oil debris analysis to optimize maintenance schedules and enhance longevity.

Cost Implications

Fluid film bearings generally have higher initial manufacturing and installation costs due to their precise design requirements and use of specialized materials. Thrust bearings often present lower upfront expenses but may incur greater maintenance costs over time because of wear and lubrication demands. Evaluating the total cost of ownership involves balancing fluid film bearings' durability and reduced downtime against thrust bearings' simpler, less expensive construction.

Choosing the Right Bearing for Your Needs

Fluid film bearings excel in applications requiring high load capacity and low friction by maintaining a lubricating film that prevents metal-to-metal contact, making them ideal for high-speed rotating machinery. Thrust bearings are specifically designed to handle axial loads and are crucial in scenarios where components experience significant thrust forces, such as in automotive transmissions and turbine shafts. Selecting the right bearing depends on the load type, operational speed, and environmental conditions, with fluid film bearings suited for dynamic, heavy-load environments and thrust bearings preferred for managing axial forces effectively.

Fluid film bearing Infographic

libterm.com

libterm.com