Solid-state slip rings provide reliable, maintenance-free electrical connectivity in rotating systems by using semiconductor components instead of traditional brushes and contacts. These devices reduce wear and tear, minimize signal noise, and enhance performance in applications requiring continuous rotation and signal transfer. Explore the rest of this article to understand how solid-state slip rings can optimize your machinery's efficiency.

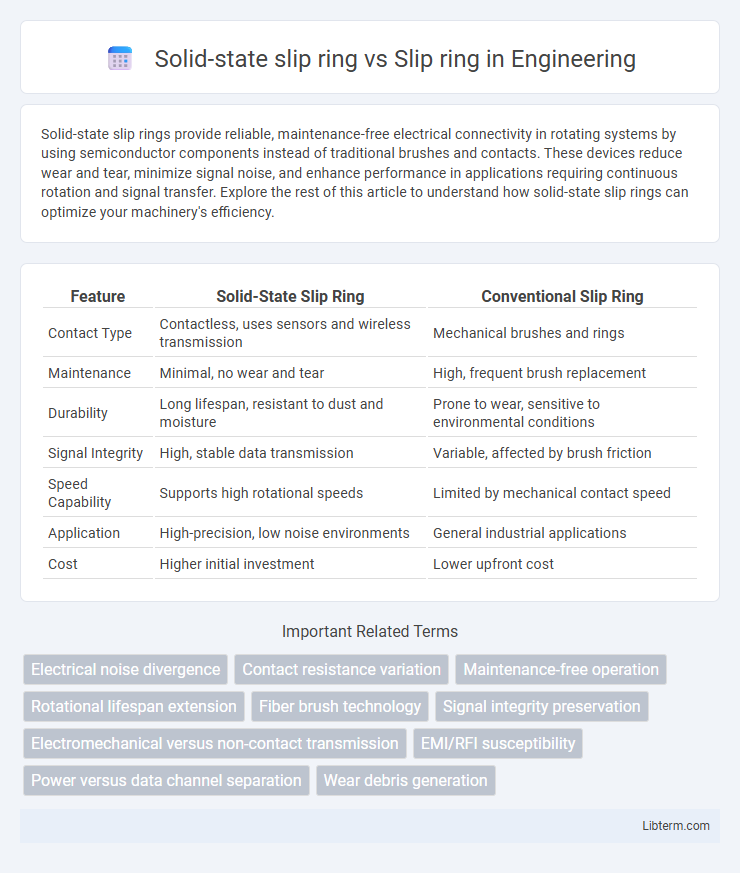

Table of Comparison

| Feature | Solid-State Slip Ring | Conventional Slip Ring |

|---|---|---|

| Contact Type | Contactless, uses sensors and wireless transmission | Mechanical brushes and rings |

| Maintenance | Minimal, no wear and tear | High, frequent brush replacement |

| Durability | Long lifespan, resistant to dust and moisture | Prone to wear, sensitive to environmental conditions |

| Signal Integrity | High, stable data transmission | Variable, affected by brush friction |

| Speed Capability | Supports high rotational speeds | Limited by mechanical contact speed |

| Application | High-precision, low noise environments | General industrial applications |

| Cost | Higher initial investment | Lower upfront cost |

Introduction to Slip Rings

Slip rings are electromechanical devices designed to transmit power and electrical signals from a stationary structure to a rotating one, commonly used in wind turbines, robotics, and industrial machinery. Solid-state slip rings utilize semiconductor components to achieve contactless transmission, reducing wear and maintenance compared to traditional mechanical slip rings with brushes and rings. The choice between solid-state and conventional slip rings depends on application requirements for durability, signal integrity, and rotational speed.

What is a Solid-State Slip Ring?

A solid-state slip ring is an advanced electrical device that transmits power and data signals without any moving parts, using semiconductor components to eliminate wear and noise common in traditional slip rings. Unlike conventional slip rings that rely on physical brushes and rings for continuous rotation connections, solid-state slip rings offer higher reliability, longer lifespan, and improved signal integrity in harsh environments. These devices are crucial in applications requiring maintenance-free operation and precise signal transmission, such as aerospace, wind turbines, and medical imaging systems.

Traditional (Electromechanical) Slip Rings Explained

Traditional electromechanical slip rings consist of rotating rings and stationary brushes that transfer electrical signals and power through physical contact, commonly used in wind turbines, robotics, and industrial machinery. These slip rings are prone to wear and maintenance due to friction and potential signal noise caused by brush contact and debris accumulation. Solid-state slip rings, in contrast, use wireless or contactless technology to provide maintenance-free operation, higher reliability, and enhanced signal integrity by eliminating mechanical wear points inherent in traditional designs.

Key Differences: Solid-State vs. Traditional Slip Rings

Solid-state slip rings utilize non-contact technology based on capacitive or optical coupling, resulting in lower maintenance, longer lifespan, and higher signal integrity compared to traditional slip rings that rely on physical brushes and rings for electrical transfer. Traditional slip rings often face wear and tear, electrical noise, and limited speed due to mechanical friction, whereas solid-state designs offer enhanced durability, reduced signal degradation, and higher rotational speed capabilities. Key differences include solid-state slip rings' improved reliability and performance for high-precision applications versus traditional slip rings' cost-effectiveness and simpler design for less demanding environments.

Performance and Efficiency Comparison

Solid-state slip rings use semiconductor components to transmit electrical signals without mechanical contact, resulting in higher reliability, lower maintenance, and reduced electrical noise compared to traditional slip rings that rely on physical brushes and contacts. Traditional slip rings may experience wear and friction, causing signal degradation and limited lifespan, whereas solid-state versions offer enhanced performance in high-speed or harsh environments by eliminating mechanical wear. Efficiency in solid-state slip rings is optimized through minimal contact resistance and reduced signal loss, making them ideal for precision applications requiring consistent, uninterrupted power and data transmission.

Reliability and Maintenance Requirements

Solid-state slip rings offer higher reliability due to the absence of mechanical contacts, reducing wear and minimizing maintenance requirements compared to traditional mechanical slip rings. Mechanical slip rings rely on brushes and rings that are prone to friction, wear, and contamination, leading to frequent inspections and part replacements. Solid-state designs eliminate contact-based failures, ensuring longer operational life and lower downtime in critical applications.

Cost Implications and Lifespan

Solid-state slip rings generally have a higher initial cost due to advanced electronic components but lower maintenance expenses over time compared to traditional slip rings with mechanical contacts. Traditional slip rings experience wear and tear from physical contact, leading to shorter lifespans and more frequent replacement or repair costs. In industrial applications, solid-state slip rings provide longer operational life and reduced downtime, making them cost-effective despite upfront investment.

Application Areas for Each Type

Solid-state slip rings excel in high-speed, precision applications such as aerospace, robotics, and medical imaging due to their contactless design and minimal electrical noise. Traditional slip rings are widely used in heavy industrial machinery, wind turbines, and rotating antennas where robust mechanical contacts handle high current loads and harsher environments. Each type's unique construction dictates suitability: solid-state slip rings suit low-maintenance, high-reliability scenarios, while conventional slip rings fit cost-sensitive, high-power applications.

Emerging Trends in Slip Ring Technology

Emerging trends in slip ring technology highlight the rise of solid-state slip rings, which feature no mechanical contacts, offering enhanced reliability and reduced maintenance compared to traditional slip rings with conductive brushes. These solid-state variants enable higher data transmission speeds and improved resistance to environmental factors, making them ideal for advanced aerospace, wind turbines, and robotics applications. Innovations in materials and miniaturization further propel solid-state slip rings as the future standard for efficient, high-performance rotary electrical interfaces.

Choosing the Right Slip Ring: Factors to Consider

Choosing the right slip ring involves evaluating factors like durability, maintenance, signal quality, and operational environment. Solid-state slip rings offer enhanced reliability with no mechanical wear, suitable for high-speed or sensitive applications requiring low electrical noise. Traditional slip rings provide cost-effective solutions for less demanding environments but may require periodic maintenance and are prone to wear.

Solid-state slip ring Infographic

libterm.com

libterm.com