Scroll compressors offer high efficiency and reliability in HVAC and refrigeration systems by using two interleaved spiral components to compress gas smoothly and continuously. Their compact design minimizes noise and vibration while maximizing energy savings and operational lifespan. Discover how your system can benefit from the advanced performance and durability of scroll compressors by reading the full article.

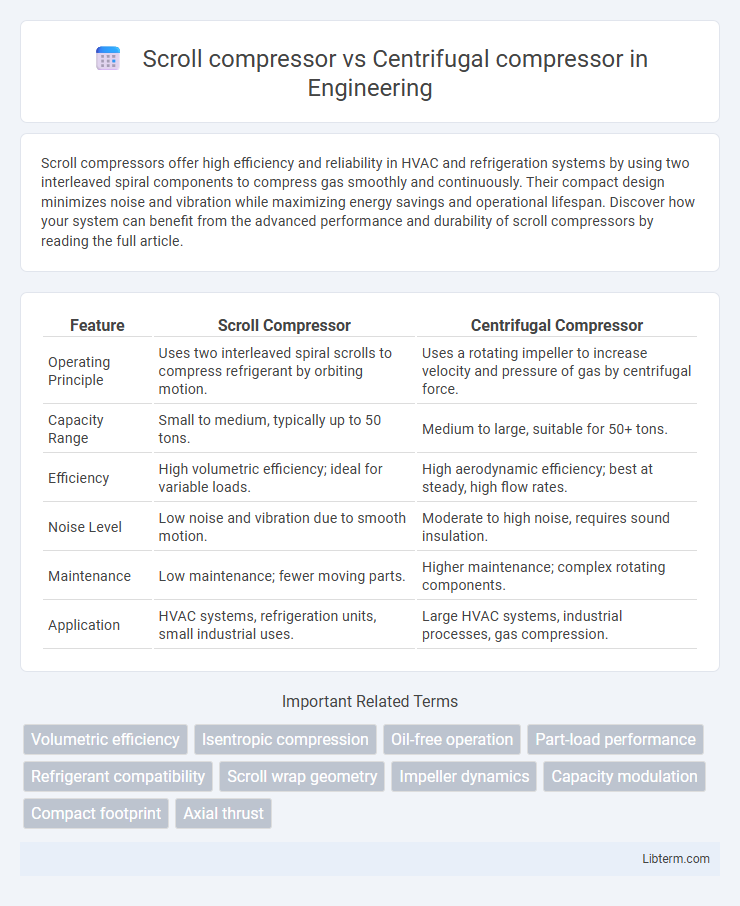

Table of Comparison

| Feature | Scroll Compressor | Centrifugal Compressor |

|---|---|---|

| Operating Principle | Uses two interleaved spiral scrolls to compress refrigerant by orbiting motion. | Uses a rotating impeller to increase velocity and pressure of gas by centrifugal force. |

| Capacity Range | Small to medium, typically up to 50 tons. | Medium to large, suitable for 50+ tons. |

| Efficiency | High volumetric efficiency; ideal for variable loads. | High aerodynamic efficiency; best at steady, high flow rates. |

| Noise Level | Low noise and vibration due to smooth motion. | Moderate to high noise, requires sound insulation. |

| Maintenance | Low maintenance; fewer moving parts. | Higher maintenance; complex rotating components. |

| Application | HVAC systems, refrigeration units, small industrial uses. | Large HVAC systems, industrial processes, gas compression. |

Introduction to Scroll and Centrifugal Compressors

Scroll compressors utilize two interleaved spiral components to compress refrigerants efficiently, making them ideal for HVAC and refrigeration applications due to their compact design and low noise operation. Centrifugal compressors employ high-speed rotating impellers to impart kinetic energy to gases, converting it into pressure, which suits large-scale industrial processes requiring high flow rates and continuous operation. Understanding the fundamental mechanisms and applications of scroll and centrifugal compressors highlights their distinct advantages in energy efficiency and operational scale.

Working Principles: Scroll vs Centrifugal Compressors

Scroll compressors operate by using two interleaved spiral scrolls, where one remains stationary while the other orbits, trapping and compressing air in progressively smaller pockets to increase pressure. Centrifugal compressors utilize a rotating impeller to accelerate air outward into a diffuser, converting velocity into pressure through centrifugal force. The key difference lies in scroll compressors employing positive displacement for efficient, low-flow applications, whereas centrifugal compressors rely on dynamic pressure generation suited for high-flow, continuous processes.

Key Design Differences

Scroll compressors utilize two interleaving spiral scrolls to compress refrigerant gas with minimal leakage and low noise, ideal for low to medium pressure applications. Centrifugal compressors employ high-speed rotating impellers to impart kinetic energy to the gas, converting it to pressure through diffusion, which suits high flow rates and industrial-scale operations. The scroll design emphasizes compactness and efficiency in small systems, while the centrifugal design prioritizes scalability and high capacity.

Efficiency Comparison

Scroll compressors typically offer higher efficiency at lower to medium flow rates due to their positive displacement mechanism, making them ideal for applications requiring precise capacity control and lower energy consumption. Centrifugal compressors excel in high flow and high-pressure scenarios with efficiency improving significantly at larger scales, benefiting from aerodynamic design and multistage configurations. Efficiency comparisons reveal scroll compressors achieve up to 85-90% isentropic efficiency in small to medium units, while centrifugal compressors can reach 90-92% efficiency but predominantly in large industrial installations.

Performance in Various Applications

Scroll compressors exhibit high volumetric efficiency and superior part-load performance, making them ideal for HVAC systems and refrigeration where energy savings and quiet operation are critical. Centrifugal compressors deliver high flow rates and pressure ratios suitable for large-scale industrial processes, such as chemical plants and gas pipelines, where continuous, high-capacity operation is required. Performance optimality depends on application scale, with scroll compressors excelling in low-to-medium capacity tasks and centrifugal compressors dominating high-capacity, high-speed environments.

Maintenance Requirements and Costs

Scroll compressors typically require less maintenance due to fewer moving parts and simpler design, resulting in lower service costs over time. Centrifugal compressors involve complex components like impellers and diffusion vanes, which demand regular inspections and more costly repairs. The initial investment for centrifugal compressors is higher, but their maintenance expenses can also significantly impact long-term operational budgets.

Energy Consumption Analysis

Scroll compressors exhibit lower energy consumption than centrifugal compressors in small to medium capacity applications due to their higher isentropic efficiency and reduced leakage rates. Centrifugal compressors are more energy-efficient in large-scale industrial settings where high flow rates and continuous operation justify their aerodynamic design advantages. Analyzing energy consumption depends on operating conditions, with scroll compressors favored for variable speed drives and centrifugal compressors excelling under steady-state, high-capacity demands.

Noise Levels and Vibration

Scroll compressors generally produce lower noise levels and reduced vibration due to their smooth, continuous compression process and fewer moving parts, making them ideal for residential and office applications. Centrifugal compressors, while capable of handling large volumes of gas efficiently, often generate higher noise and vibration due to high-speed rotating impellers and aerodynamic forces. Advanced soundproofing and vibration isolation techniques are typically required to manage noise levels in centrifugal compressor installations.

Pros and Cons of Each Compressor Type

Scroll compressors offer high efficiency, low noise levels, and compact design, making them ideal for residential HVAC and small-scale refrigeration. Their main limitations include lower capacity and sensitivity to particulate contamination compared to centrifugal compressors. Centrifugal compressors excel in handling large volumes of air with continuous operation and excellent reliability but tend to have higher initial costs, larger footprints, and require precise maintenance to avoid efficiency losses.

Choosing the Right Compressor for Your Needs

Scroll compressors offer high efficiency, quieter operation, and compact design, making them ideal for residential and light commercial HVAC systems. Centrifugal compressors handle larger volumes and higher pressures, preferred in large industrial and commercial applications requiring continuous, heavy-duty performance. Evaluate factors such as capacity requirements, space constraints, noise tolerance, and maintenance preferences to select the optimal compressor type for your specific needs.

Scroll compressor Infographic

libterm.com

libterm.com