A tap drill is essential for preparing the correct hole size before threading, ensuring precise and clean internal threads. Using the right tap drill size prevents threading errors and increases the durability of your threaded components. Discover how to select the perfect tap drill size and improve your machining accuracy by reading the full article.

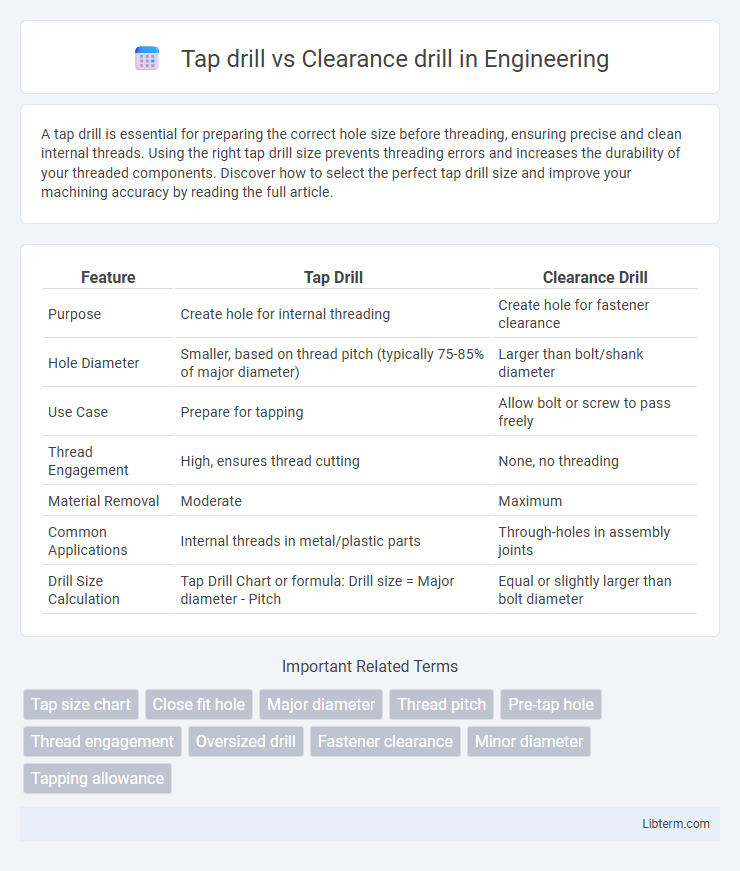

Table of Comparison

| Feature | Tap Drill | Clearance Drill |

|---|---|---|

| Purpose | Create hole for internal threading | Create hole for fastener clearance |

| Hole Diameter | Smaller, based on thread pitch (typically 75-85% of major diameter) | Larger than bolt/shank diameter |

| Use Case | Prepare for tapping | Allow bolt or screw to pass freely |

| Thread Engagement | High, ensures thread cutting | None, no threading |

| Material Removal | Moderate | Maximum |

| Common Applications | Internal threads in metal/plastic parts | Through-holes in assembly joints |

| Drill Size Calculation | Tap Drill Chart or formula: Drill size = Major diameter - Pitch | Equal or slightly larger than bolt diameter |

Understanding Tap Drills and Clearance Drills

Tap drills are specifically sized holes that allow threads to be cut effectively while maintaining sufficient material strength around the threads. Clearance drills create a hole larger than the screw or bolt diameter, enabling free movement without threading, which is essential for assembly alignment. Understanding the distinction between tap drills and clearance drills ensures proper hole preparation for threaded fasteners, optimizing mechanical performance and assembly fit.

Key Differences Between Tap Drill and Clearance Drill

Tap drill is specifically sized to create a pilot hole that allows for precise threading by removing just enough material for the tap to form threads without excessive force, whereas clearance drill holes are larger to provide ample space for the screw or bolt to pass through without engaging threads. Tap drills typically measure approximately 85-95% of the major thread diameter, ensuring optimal thread engagement and strength. Clearance drills are sized according to the screw's outer diameter to prevent friction and allow easy insertion and alignment in assembly processes.

Purpose of a Tap Drill

The purpose of a tap drill is to create a hole size that allows for the proper threading when using a tap, ensuring sufficient material remains for strong internal threads. Tap drills are typically smaller than clearance drills, which provide a hole large enough for fasteners to pass through without engaging threads. Correct tap drill selection is critical for thread engagement, tool life, and structural integrity in threaded assemblies.

Purpose of a Clearance Drill

A clearance drill is designed to create a hole slightly larger than the nominal screw size, allowing for easy insertion and free movement of fasteners without threading engagement. Unlike tap drills that prepare holes for tapping threads, clearance drills ensure proper alignment and prevent binding or damage to mating parts. This type of drill is essential in assemblies where screws pass through one component to securely fasten into another.

How to Select the Correct Tap Drill Size

Selecting the correct tap drill size involves understanding the relationship between the desired thread size and the material thickness. The tap drill diameter is typically calculated by subtracting the thread pitch from the nominal thread diameter to ensure proper thread engagement without excessive stress. Clearance drill sizes are larger than tap drills, providing sufficient space for a bolt or screw to pass through without threading the hole, which is essential for assembly and alignment in mechanical applications.

Choosing the Right Clearance Drill Size

Selecting the correct clearance drill size depends on the bolt or screw diameter to ensure proper fit without thread interference. Typically, clearance drill diameters are slightly larger than the bolt's major diameter, allowing smooth passage and preventing thread damage. Using standard charts or manufacturer guidelines helps in matching clearance drills accurately to fastener specifications for optimal assembly performance.

Application Scenarios: Tap Drill vs Clearance Drill

Tap drills are designed to create precise pilot holes slightly smaller than the final thread diameter, ideal for applications where strong internal threads are required in materials like steel or aluminum. Clearance drills produce holes larger than the bolt or screw diameter, allowing fasteners to pass freely through, which is essential for assembly processes needing easy alignment or thermal expansion. Tap drills are commonly used in threading components, whereas clearance drills are preferred in through-hole fastening and adjustable joint scenarios.

Consequences of Using the Wrong Drill Type

Using the wrong drill type, such as a clearance drill instead of a tap drill, leads to improper hole dimensions that compromise thread integrity and cause poor fitment in assemblies. A tap drill hole that is too large results in weak, stripped threads, while a clearance drill used for threading tasks can cause excessive material removal and failure to engage threads properly. Incorrect drill selection increases machining time, tool wear, and potential for costly part rework or rejection in manufacturing processes.

Tips for Effective Drilling Operations

Choosing the correct tap drill size ensures optimal thread strength and prevents tool breakage, while using the appropriate clearance drill diameter allows smooth bolt or screw passage without damaging the material. For effective drilling operations, maintain sharp drill bits, use proper feed rates, and apply coolant to reduce heat and extend tool life. Precise alignment and consistent drilling speed enhance hole quality, minimizing rework and improving assembly fit.

Common Mistakes and How to Avoid Them

Choosing the wrong drill size between tap drill and clearance drill often leads to threading errors or poor fitment, causing issues such as thread stripping or excessive play in fasteners. Common mistakes include using a tap drill that is too small, resulting in difficult tapping and weak threads, or a clearance drill that is too tight, which prevents smooth bolt insertion and can damage threads. To avoid these errors, carefully reference industry-standard charts like the Machinery's Handbook, verify hole sizes with precision measuring tools, and perform test assemblies to ensure proper thread engagement and clearance.

Tap drill Infographic

libterm.com

libterm.com