An electronic pressure calibrator offers precise measurement and calibration of pressure instruments, enhancing accuracy and efficiency in various industrial applications. This device simplifies the testing process by providing digital readouts and automated functions, reducing human error and saving time. Discover how using an electronic pressure calibrator can improve your pressure system's performance and reliability in the following article.

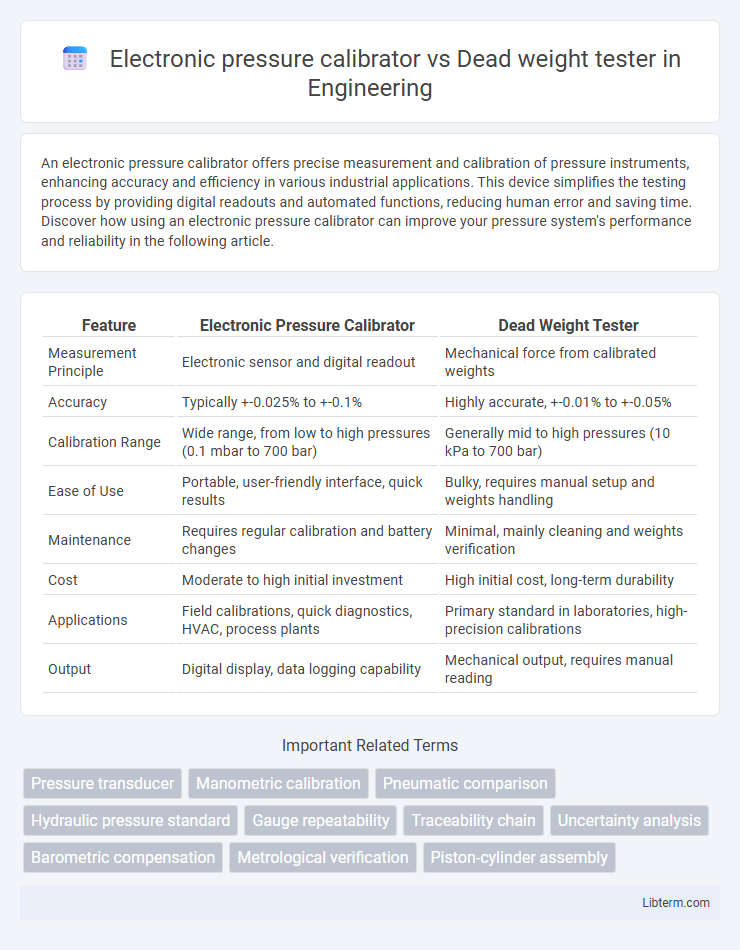

Table of Comparison

| Feature | Electronic Pressure Calibrator | Dead Weight Tester |

|---|---|---|

| Measurement Principle | Electronic sensor and digital readout | Mechanical force from calibrated weights |

| Accuracy | Typically +-0.025% to +-0.1% | Highly accurate, +-0.01% to +-0.05% |

| Calibration Range | Wide range, from low to high pressures (0.1 mbar to 700 bar) | Generally mid to high pressures (10 kPa to 700 bar) |

| Ease of Use | Portable, user-friendly interface, quick results | Bulky, requires manual setup and weights handling |

| Maintenance | Requires regular calibration and battery changes | Minimal, mainly cleaning and weights verification |

| Cost | Moderate to high initial investment | High initial cost, long-term durability |

| Applications | Field calibrations, quick diagnostics, HVAC, process plants | Primary standard in laboratories, high-precision calibrations |

| Output | Digital display, data logging capability | Mechanical output, requires manual reading |

Introduction to Pressure Calibration

Pressure calibration ensures accuracy in measuring instruments by comparing device readings against a known standard. Electronic pressure calibrators use digital sensors and electronics to generate and measure pressure, providing quick, precise readings with data logging capabilities. Dead weight testers apply calibrated weights to generate exact pressures, known for their high accuracy and reliability in primary calibration processes.

Overview of Electronic Pressure Calibrators

Electronic pressure calibrators provide fast, accurate pressure measurement and calibration through digital sensors and microprocessor control, enabling real-time data display and analysis. These instruments offer portability, ease of use, and compatibility with multiple pressure units, making them ideal for field service and maintenance tasks. Unlike dead weight testers, which rely on gravity and mechanical weights, electronic calibrators deliver faster results without manual adjustments, improving efficiency in pressure system validation.

Overview of Dead Weight Testers

Dead weight testers provide highly accurate pressure calibration by applying known weights to generate precise pressure values, making them ideal for verifying pressure gauges and sensors. They operate on the principle of balancing a piston-cylinder assembly with calibrated weights, offering stable and reproducible measurements without reliance on electronic components. Dead weight testers are valued for their reliability in high-precision industrial and laboratory environments where traceable standard pressure references are required.

Working Principles: Electronic vs Dead Weight Methods

Electronic pressure calibrators use piezoelectric or strain gauge sensors to convert pressure into an electrical signal, providing instant and precise digital readouts. Dead weight testers operate by balancing a known weight on a piston against the pressure in the system, producing highly accurate and traceable calibration standards through mechanical means. The electronic method offers rapid measurements and ease of use, while the dead weight method ensures fundamental accuracy by direct physical measurement.

Accuracy Comparison: Electronic Calibrators vs Dead Weight Testers

Electronic pressure calibrators offer high accuracy with typical uncertainty levels around +-0.025% of full scale, providing rapid measurements and ease of use in diverse field conditions. Dead weight testers achieve superior precision, often reaching uncertainties as low as +-0.005% by directly applying known weights to generate pressure, making them the gold standard for primary calibration. While electronic calibrators enhance efficiency and portability, dead weight testers remain unmatched for calibration traceability and the highest accuracy requirements.

Usability and Practical Considerations

Electronic pressure calibrators offer high portability, fast readings, and ease of use with digital displays and data logging capabilities, making them suitable for field calibration tasks. Dead weight testers, although less portable due to their bulky design and manual operation, provide unparalleled accuracy and stability ideal for laboratory and primary standard applications. Practical considerations involve balancing the need for precision and convenience, where electronic calibrators excel in efficiency, while dead weight testers remain the benchmark for traceable pressure measurements.

Maintenance and Calibration Requirements

Electronic pressure calibrators require periodic calibration using traceable standards to maintain accuracy, often involving software updates and battery replacements for optimal performance. Dead weight testers demand regular cleaning, lubrication, and precise mass verification to ensure reliable pressure generation, with maintenance typically performed less frequently but involving mechanical components. Both devices rely on strict calibration schedules, but electronic calibrators offer quicker adjustments and diagnostics, whereas dead weight testers provide time-tested mechanical accuracy with more hands-on upkeep.

Application Suitability: Industry Use Cases

Electronic pressure calibrators are ideal for fast, on-site calibration in industries such as HVAC, automotive, and manufacturing, where portability and quick accuracy checks are essential. Dead weight testers provide unmatched precision and stability for laboratory settings and calibration labs, extensively used in petrochemical, aerospace, and power generation industries requiring traceable, high-accuracy measurements. The choice depends on balancing field usability versus laboratory-grade accuracy in pressure instrumentation maintenance and verification.

Cost Analysis and Long-Term Value

Electronic pressure calibrators generally have a higher initial cost compared to dead weight testers but offer greater versatility and faster calibration processes, which reduces labor expenses over time. Dead weight testers, while more affordable upfront and known for their accuracy and reliability, require regular maintenance and calibration fluid replacement, potentially increasing long-term operational costs. Evaluating the total cost of ownership includes considering electronic calibrators' software upgrades and enhanced data management capabilities that contribute to improved efficiency and compliance in the long run.

Choosing the Right Pressure Calibration Tool

Selecting the right pressure calibration tool depends on accuracy requirements, application environment, and budget. Electronic pressure calibrators offer rapid, portable, and user-friendly solutions with digital displays and data logging, ideal for routine field calibration. Dead weight testers provide highly precise, traceable pressure standards suitable for laboratory settings and calibration of critical instruments where accuracy is paramount.

Electronic pressure calibrator Infographic

libterm.com

libterm.com