Fatigue strength measures a material's ability to withstand repeated cyclic loading without failure, making it critical in the design of components subjected to fluctuating stresses. Understanding fatigue strength helps ensure the durability and safety of structures such as bridges, aircraft, and machinery subjected to continuous stress variations. Explore the full article to learn how fatigue strength impacts your project's longevity and performance.

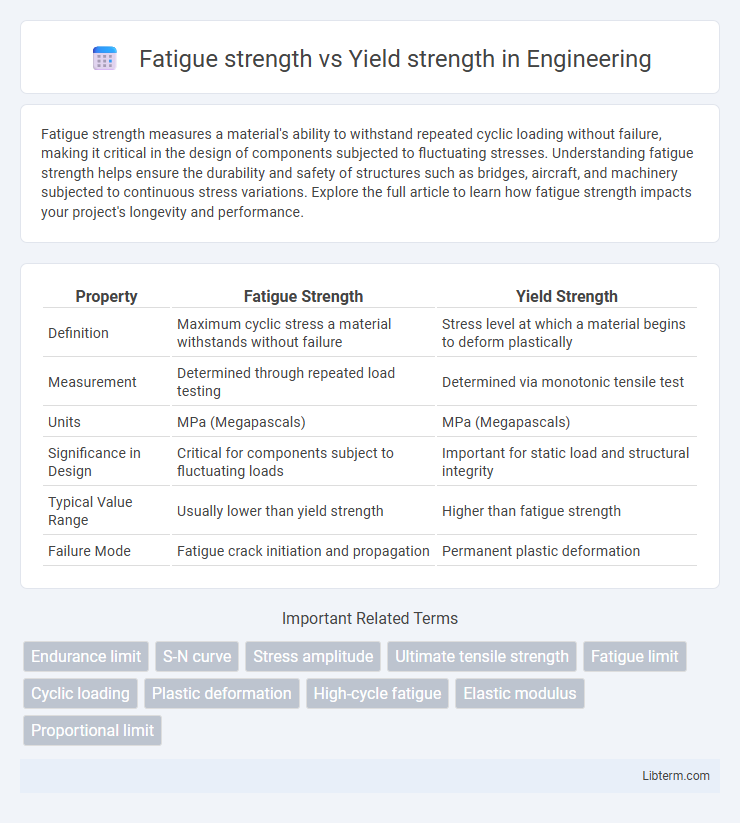

Table of Comparison

| Property | Fatigue Strength | Yield Strength |

|---|---|---|

| Definition | Maximum cyclic stress a material withstands without failure | Stress level at which a material begins to deform plastically |

| Measurement | Determined through repeated load testing | Determined via monotonic tensile test |

| Units | MPa (Megapascals) | MPa (Megapascals) |

| Significance in Design | Critical for components subject to fluctuating loads | Important for static load and structural integrity |

| Typical Value Range | Usually lower than yield strength | Higher than fatigue strength |

| Failure Mode | Fatigue crack initiation and propagation | Permanent plastic deformation |

Understanding Fatigue Strength: Definition and Importance

Fatigue strength refers to the maximum stress a material can withstand for a specified number of cycles without failure, distinct from yield strength which measures the stress at which permanent deformation begins. Understanding fatigue strength is crucial in designing components exposed to repeated or fluctuating loads, such as aircraft wings or automotive suspension parts, to prevent unexpected fractures. This property helps engineers predict lifespan and ensure durability under cyclic stresses, enhancing safety and reliability in mechanical systems.

What Is Yield Strength? Key Concepts Explained

Yield strength is the maximum stress a material can withstand without permanent deformation, marking the transition from elastic to plastic behavior. It defines the stress level at which a material begins to deform irreversibly under static loading conditions. Understanding yield strength is crucial for designing components that must maintain structural integrity under applied loads without experiencing permanent shape changes.

Fatigue Strength vs Yield Strength: Core Differences

Fatigue strength measures a material's ability to withstand repeated cyclic loading without failure, while yield strength indicates the maximum stress a material can endure before plastic deformation occurs. Fatigue strength is critical for components subjected to fluctuating stresses over time, such as rotating shafts or bridges, ensuring longevity under variable loads. Yield strength provides a threshold for permanent deformation under static loads, making it vital for structural design and material selection in engineering applications.

How Materials Respond: Cyclic vs Static Loads

Fatigue strength measures a material's ability to withstand repeated cyclic loading without failure, while yield strength defines the stress level at which a material undergoes permanent deformation under static load. Under cyclic loads, microscopic cracks can initiate and propagate, causing fatigue failure below the yield strength threshold. Yield strength is critical for static load applications where permanent deformation must be avoided, whereas fatigue strength governs performance in components subjected to fluctuating stresses over time.

Factors Influencing Fatigue Strength in Materials

Fatigue strength in materials is primarily influenced by factors such as surface finish, grain size, and the presence of stress concentrators like notches or cracks. Environmental conditions, including temperature and corrosion, can significantly reduce fatigue strength by promoting crack initiation and propagation. Microstructural properties, such as phase distribution and inclusions, also play a critical role in determining a material's resistance to cyclic loading compared to its yield strength.

Determinants of Yield Strength and Material Deformation

Yield strength is determined by factors such as crystal structure, grain size, and the presence of dislocations or alloying elements that hinder dislocation movement, influencing the onset of permanent material deformation. Fatigue strength depends primarily on the material's ability to resist crack initiation and propagation under cyclic loading, which relates to surface finish, microstructural defects, and environmental conditions. Understanding the interplay between these determinants allows engineers to predict material behavior under both static and dynamic stresses for optimized design.

Testing Methods: Fatigue Strength vs Yield Strength

Fatigue strength is evaluated using cyclic loading tests such as rotating bending or axial fatigue tests, which measure a material's resistance to failure under repeated stress cycles. Yield strength is determined through monotonic tensile testing, where the material is subjected to a steadily increasing load until it deforms plastically. Both testing methods provide critical insights: fatigue tests simulate real-world fluctuating stresses, while tensile tests establish the maximum stress before permanent deformation occurs.

Design Considerations: When to Prioritize Each Strength

Design considerations dictate prioritizing fatigue strength in components subjected to cyclic loading, such as rotating shafts or aircraft wings, where repeated stress can cause failure below yield strength. Yield strength becomes critical in static load applications, including structural beams and machine frames, where permanent deformation must be avoided under maximum expected loads. Optimizing materials for specific performance demands requires balancing fatigue resistance for durability and yield strength for load-bearing capacity in engineering design.

Real-World Applications: Industry Examples and Case Studies

Fatigue strength and yield strength are critical parameters in engineering materials used in automotive and aerospace industries where cyclic loading and stress endurance determine component lifespan. In bridge construction, fatigue strength governs design to prevent failure under repeated traffic loads, while yield strength ensures structures remain within elastic limits during peak stresses. Case studies in turbine blade manufacturing highlight the trade-off between high fatigue strength for long-term durability and yield strength for immediate load-bearing capacity.

Enhancing Material Performance: Improving Fatigue and Yield Strength

Enhancing material performance requires focused improvements in both fatigue strength and yield strength to ensure durability and reliability under cyclic and static loads. Advances in alloy composition, heat treatment, and microstructural refinement significantly increase yield strength while simultaneously improving resistance to fatigue crack initiation and propagation. Incorporating surface treatments such as shot peening and coatings further enhances fatigue life by reducing stress concentrators and delaying material failure.

Fatigue strength Infographic

libterm.com

libterm.com