A recuperator is a heat recovery device designed to improve energy efficiency by capturing waste heat from exhaust gases and transferring it to incoming air or fluids. This process helps reduce energy consumption in heating, ventilation, and industrial systems by reclaiming heat that would otherwise be lost. Explore the rest of the article to learn how a recuperator can significantly enhance your system's performance and save costs.

Table of Comparison

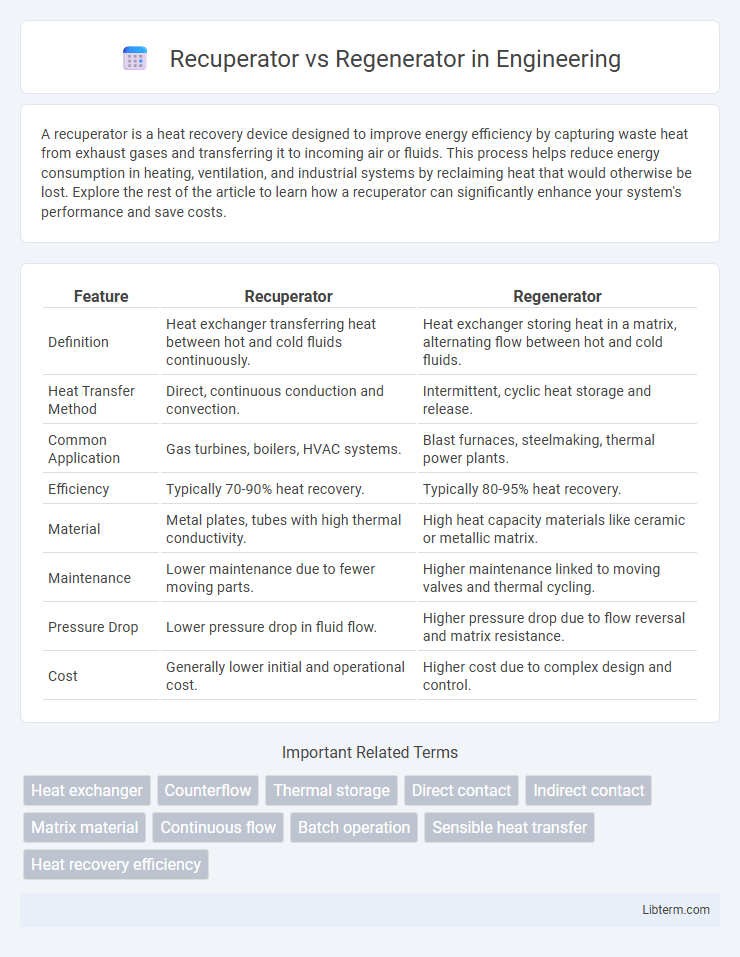

| Feature | Recuperator | Regenerator |

|---|---|---|

| Definition | Heat exchanger transferring heat between hot and cold fluids continuously. | Heat exchanger storing heat in a matrix, alternating flow between hot and cold fluids. |

| Heat Transfer Method | Direct, continuous conduction and convection. | Intermittent, cyclic heat storage and release. |

| Common Application | Gas turbines, boilers, HVAC systems. | Blast furnaces, steelmaking, thermal power plants. |

| Efficiency | Typically 70-90% heat recovery. | Typically 80-95% heat recovery. |

| Material | Metal plates, tubes with high thermal conductivity. | High heat capacity materials like ceramic or metallic matrix. |

| Maintenance | Lower maintenance due to fewer moving parts. | Higher maintenance linked to moving valves and thermal cycling. |

| Pressure Drop | Lower pressure drop in fluid flow. | Higher pressure drop due to flow reversal and matrix resistance. |

| Cost | Generally lower initial and operational cost. | Higher cost due to complex design and control. |

Introduction to Heat Recovery Technologies

Heat recovery technologies improve energy efficiency by capturing waste heat and reusing it in industrial processes. Recuperators transfer heat directly between hot and cold fluids using a fixed heat exchanger, enhancing system performance without mixing the streams. Regenerators store heat temporarily in a thermal mass before releasing it to the cold fluid, enabling higher temperature recovery in cyclical operations.

What is a Recuperator?

A recuperator is a heat exchanger designed to recover waste heat from exhaust gases and transfer it to incoming combustion air or process fluids, enhancing overall thermal efficiency. Commonly used in industrial furnaces and gas turbines, recuperators utilize continuous metal surfaces to facilitate direct heat transfer between two gas streams without mixing. Their efficiency and compact design make them ideal for applications requiring rapid heat recovery and energy savings.

What is a Regenerator?

A regenerator is a heat exchanger that temporarily stores thermal energy from hot gases and transfers it to cold gases by cycling the flow between two chambers filled with a heat-retaining medium, such as ceramic or metal. Unlike a recuperator, which uses separate channels for continuous heat exchange, a regenerator operates in a cyclic process, allowing intermittent heat storage and release to improve energy efficiency in systems like gas turbines and industrial furnaces. The key advantage of a regenerator lies in its ability to recover high-temperature waste heat, reducing fuel consumption and enhancing thermal performance.

Working Principles: Recuperator vs Regenerator

A recuperator transfers heat directly from exhaust gases to incoming air through a heat exchanger, using continuous flow paths to maximize thermal efficiency. A regenerator stores heat in a thermal mass during exhaust phases and releases it to incoming air during the charge cycle, operating cyclically with periodic flow reversal. Recuperators provide steady-state heat recovery, while regenerators handle intermittent heat storage and transfer, making each suitable for different applications based on heat exchange dynamics.

Types of Recuperators

Recuperators, essential in heat recovery systems, come primarily in plate, tubular, and spiral types, each designed to optimize heat transfer efficiency in different industrial applications. Plate recuperators use stacked metal plates to separate air streams and achieve rapid heat exchange, ideal for high-temperature processes. Tubular recuperators consist of bundles of tubes to isolate hot and cold gases, providing durability and ease of maintenance in power plants and automotive exhaust systems.

Types of Regenerators

Regenerators, commonly used in heat recovery systems, include rotary, fixed-matrix, and honeycomb types, each designed to optimize thermal energy transfer by cyclically storing and releasing heat. Rotary regenerators feature a rotating heat storage matrix that continuously absorbs heat from hot gases and transfers it to incoming cold air, offering high efficiency in industrial applications. Fixed-matrix regenerators rely on a stationary thermal mass for heat exchange, while honeycomb regenerators utilize a structured array of channels to maximize surface area and improve heat transfer rates.

Efficiency Comparison: Recuperator and Regenerator

Recuperators typically achieve lower efficiency than regenerators due to continuous heat exchange without thermal storage, resulting in efficiency rates around 60-70%, while regenerators can reach 75-85% efficiency by storing and periodically transferring heat between hot and cold gas streams. Regenerators, often used in high-temperature applications like gas turbines and steel furnaces, minimize energy losses through cyclic heat exchange, improving overall system thermal efficiency. The choice between recuperator and regenerator depends on operating temperature, cost constraints, and required heat recovery effectiveness.

Applications in Industry

Recuperators are widely used in industries such as power generation and metal processing for continuous heat recovery from exhaust gases, improving energy efficiency in furnaces and gas turbines. Regenerators find applications in steel manufacturing and glass production, where intermittent heat storage and release cycles enhance thermal performance during batch processing. Both heat exchangers play critical roles in reducing fuel consumption and emissions across various industrial sectors.

Advantages and Disadvantages

Recuperators offer continuous heat exchange with lower pressure drops and simpler design, making them highly efficient for gases with constant flow rates, but they struggle with high-temperature applications and fouling. Regenerators provide superior thermal energy recovery by cycling heat storage media, which is advantageous for high-temperature processes, yet they involve more complex operation, higher maintenance costs, and intermittent flow patterns. Selecting between recuperators and regenerators depends on factors such as temperature range, maintenance capabilities, and the specific application's thermal recovery requirements.

Choosing Between Recuperator and Regenerator

Choosing between a recuperator and a regenerator depends on factors like operational temperature, heat transfer efficiency, and system design. Recuperators are optimal for continuous, steady-state applications with moderate temperatures, offering lower pressure losses and simpler maintenance. Regenerators excel in applications requiring high-temperature heat recovery and cyclic operation, providing superior heat exchange efficiency despite more complex design and higher maintenance requirements.

Recuperator Infographic

libterm.com

libterm.com