Fillet refers to a boneless cut of meat or fish prized for its tenderness and flavor, often used in gourmet cooking and easy preparation. Proper filleting techniques enhance the quality of your dish by maximizing yield and minimizing waste. Explore the rest of the article to master the art of filleting and elevate your culinary skills.

Table of Comparison

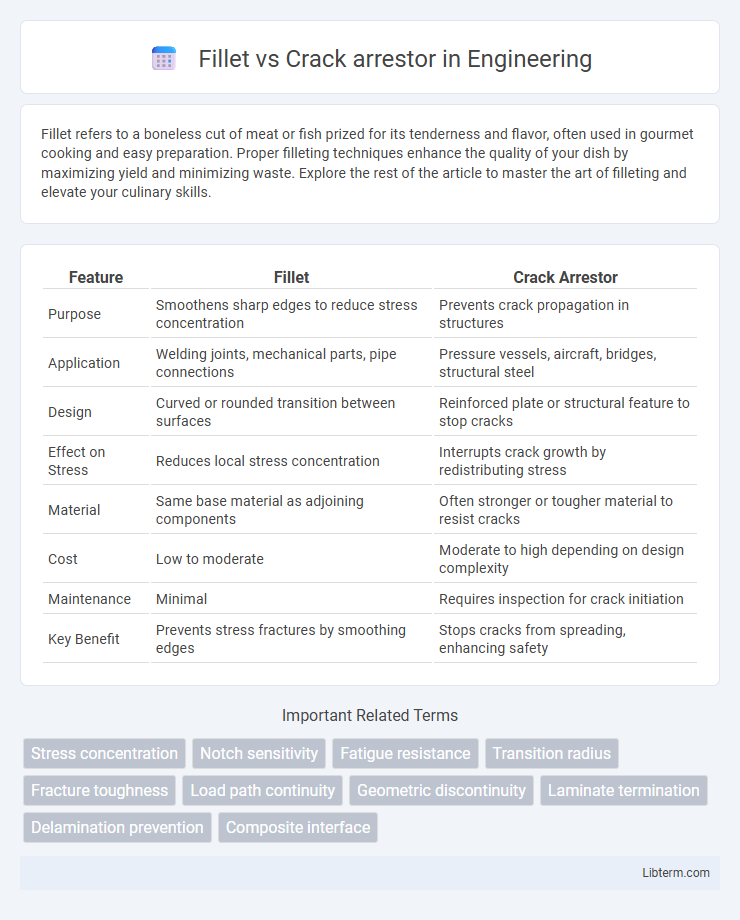

| Feature | Fillet | Crack Arrestor |

|---|---|---|

| Purpose | Smoothens sharp edges to reduce stress concentration | Prevents crack propagation in structures |

| Application | Welding joints, mechanical parts, pipe connections | Pressure vessels, aircraft, bridges, structural steel |

| Design | Curved or rounded transition between surfaces | Reinforced plate or structural feature to stop cracks |

| Effect on Stress | Reduces local stress concentration | Interrupts crack growth by redistributing stress |

| Material | Same base material as adjoining components | Often stronger or tougher material to resist cracks |

| Cost | Low to moderate | Moderate to high depending on design complexity |

| Maintenance | Minimal | Requires inspection for crack initiation |

| Key Benefit | Prevents stress fractures by smoothing edges | Stops cracks from spreading, enhancing safety |

Introduction: Fillet vs Crack Arrestor

Fillet welds provide smooth transitions between two metal surfaces, reducing stress concentration and improving fatigue resistance in structural joints. Crack arrestors are specialized features or devices integrated into structures to stop crack propagation and prevent catastrophic failure, often used in high-stress or critical applications. Understanding the differences between fillet welds and crack arrestors is essential for optimizing structural integrity and durability in engineering design.

Understanding Fillets: Definition and Purpose

Fillets are concave grooves used in engineering to reduce stress concentration at the junction of two surfaces, enhancing structural integrity by distributing applied loads more evenly. They are primarily designed to smooth transitions between intersecting parts, minimizing the risk of cracks initiating at sharp corners. In contrast to crack arrestors, which are intended to stop the propagation of existing cracks, fillets focus on preventing stress-induced cracks through optimized geometry.

What is a Crack Arrestor?

A crack arrestor is a specially designed structural feature or component used in engineering to prevent the propagation of cracks in metal or composite materials, thereby enhancing the integrity and safety of critical structures. It works by redistributing stress concentrations and stopping crack growth, commonly applied in pressure vessels, aircraft, and pipelines. Fillets, in contrast, are rounded transitions in geometry that reduce stress concentration but do not specifically function as crack arrestors.

Key Differences: Fillet and Crack Arrestor

Fillets are smooth, rounded interior corners designed to reduce stress concentration by distributing load evenly across a joint, which enhances structural integrity in welded or fabricated components. Crack arrestors, on the other hand, are specialized features or devices integrated into materials or structures to halt the propagation of cracks by absorbing or redirecting stress waves, thereby preventing catastrophic failure. Key differences include fillets primarily improving load distribution at joints through geometric modifications, while crack arrestors function to stop crack growth using targeted interventions such as holes, slots, or reinforcements.

Applications of Fillets in Engineering

Fillets are widely applied in engineering to reduce stress concentration at sharp corners, enhancing the durability and fatigue life of components such as beams, shafts, and machined parts. Their smooth curved transitions improve load distribution and minimize crack initiation points, which is critical in aerospace, automotive, and structural engineering applications. Fillets also facilitate manufacturability by easing tool paths and reducing material waste during machining and casting processes.

Common Uses of Crack Arrestors

Crack arrestors are commonly used in pressure vessels, pipelines, and storage tanks to prevent the propagation of cracks, enhancing the structural integrity and safety of the equipment. Unlike fillets, which primarily serve to reduce stress concentration at welds or corners, crack arrestors are specifically designed with thicker or strategically placed material to stop cracks from spreading under operational stresses. Industries such as oil and gas, chemical processing, and power generation rely heavily on crack arrestors to mitigate failure risks and prolong the lifespan of critical infrastructure components.

Structural Benefits: Fillet vs Crack Arrestor

Fillets enhance structural integrity by evenly distributing stress at joints, reducing stress concentrations and minimizing the risk of crack initiation in welded or machined components. Crack arrestors, designed to interrupt crack propagation, provide a targeted structural benefit by halting the growth of existing cracks, thereby preventing catastrophic failure. Together, fillets improve overall durability through stress management, while crack arrestors ensure long-term structural resilience by limiting crack extension.

Material Considerations for Fillets and Crack Arrestors

Material considerations for fillets and crack arrestors revolve around strength, toughness, and fatigue resistance to prevent crack initiation and propagation effectively. Fillets require materials with high ductility and smooth surface finish capability to reduce stress concentration, while crack arrestors need tough, high-fracture-toughness alloys that can absorb and blunt crack growth under cyclic loading. Selection often involves metals such as stainless steel or aluminum alloys tailored for structural integrity and resistance to environmental degradation in aerospace or mechanical applications.

Design Guidelines: Choosing Between Fillet and Crack Arrestor

Fillet welds provide smooth stress distribution in low to moderate load applications, ensuring fewer stress concentrations at joints. Crack arrestors are essential in high-stress areas where potential crack propagation could lead to catastrophic failure, often implemented as geometric discontinuities or reinforcements that halt crack growth. Design guidelines recommend fillets for general structural connections, while crack arrestors are prioritized in critical components subject to fatigue or fracture, optimizing safety and durability.

Conclusion: Selecting the Right Solution

Choosing between a fillet and a crack arrestor depends on the specific structural requirements and stress distribution of the component. Fillets are ideal for reducing stress concentration at sharp corners by smoothing transitions, while crack arrestors are designed to halt the propagation of existing cracks, enhancing safety and durability. Assessing load conditions, material properties, and failure risks ensures the selection of the most effective solution for preventing structural damage.

Fillet Infographic

libterm.com

libterm.com