Abrasive machining uses abrasive particles to remove material from a workpiece with high precision and surface finish. This method excels in shaping hard or brittle materials where traditional machining is ineffective. Explore the rest of the article to understand how abrasive machining can enhance your manufacturing processes.

Table of Comparison

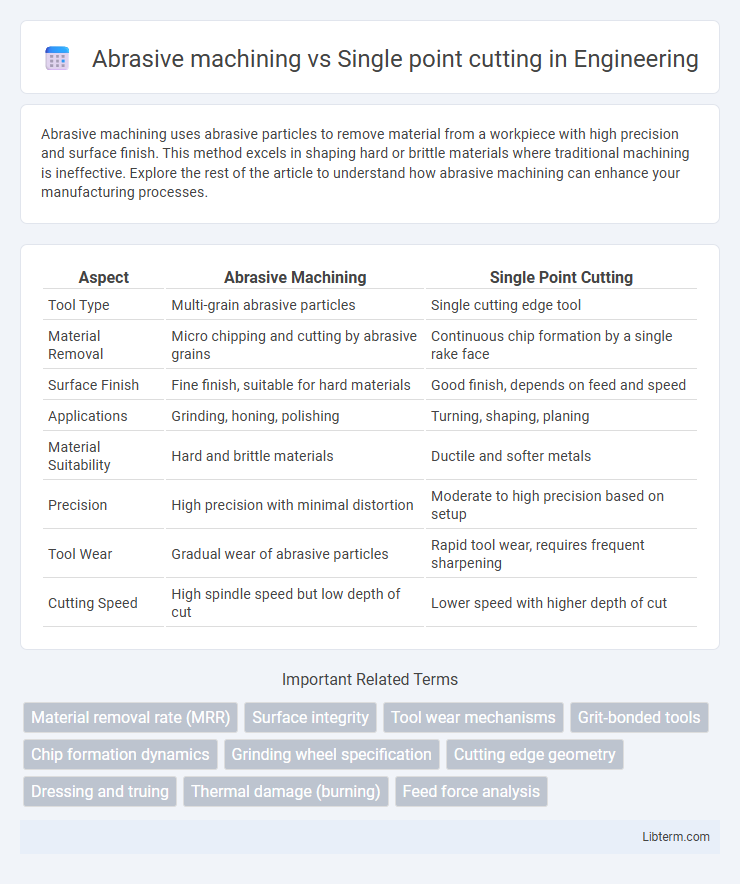

| Aspect | Abrasive Machining | Single Point Cutting |

|---|---|---|

| Tool Type | Multi-grain abrasive particles | Single cutting edge tool |

| Material Removal | Micro chipping and cutting by abrasive grains | Continuous chip formation by a single rake face |

| Surface Finish | Fine finish, suitable for hard materials | Good finish, depends on feed and speed |

| Applications | Grinding, honing, polishing | Turning, shaping, planing |

| Material Suitability | Hard and brittle materials | Ductile and softer metals |

| Precision | High precision with minimal distortion | Moderate to high precision based on setup |

| Tool Wear | Gradual wear of abrasive particles | Rapid tool wear, requires frequent sharpening |

| Cutting Speed | High spindle speed but low depth of cut | Lower speed with higher depth of cut |

Introduction to Abrasive Machining and Single Point Cutting

Abrasive machining utilizes abrasive grains bonded in a tool or loose form to remove material through micro-cutting, grinding, or erosion, enabling high-precision finishing on hard and brittle materials. Single point cutting involves a single cutting edge tool that removes material through shear deformation, typically employed in turning, shaping, and planing operations to achieve specific geometries and surface finishes. Both processes are integral in manufacturing, with abrasive machining excelling in surface refinement and single point cutting providing dimensional accuracy in shaping metal components.

Principles of Abrasive Machining

Abrasive machining operates on the principle of material removal through micro-cutting, micro-fracture, and plowing by abrasive grains acting as numerous small cutting edges, which contrasts with the single, well-defined cutting edge in single point cutting. This process relies on the random distribution and varying sharpness of abrasive particles, allowing it to machine hard, brittle, and heat-sensitive materials with minimal thermal damage. The mechanics of abrasive machining involve complex interactions between abrasive particles and workpiece surface, leading to improved surface finish and precision in finishing and grinding applications.

Fundamentals of Single Point Cutting

Single point cutting involves a single cutting edge removing material from a workpiece to create a defined shape or surface, relying on precise control of cutting speed, feed, and depth of cut to achieve desired results. The fundamental principles include chip formation through shear deformation, understanding the rake angle, clearance angle, and cutting forces that influence tool wear and surface finish. Unlike abrasive machining which uses multiple loose or bonded abrasive grains for material removal, single point cutting emphasizes tool geometry and material properties for efficiency and accuracy in turning, shaping, and boring operations.

Material Removal Mechanisms

Abrasive machining removes material through the micro-cutting and plowing actions of abrasive particles embedded in a wheel or belt, creating multiple minute chip formations and fracture zones. Single point cutting involves a single cutting edge shearing material at a defined rake angle, generating continuous or segmented chips based on workpiece properties and cutting conditions. The material removal mechanism in abrasive machining relies on high-frequency impacts and erosion, whereas single point cutting emphasizes plastic deformation and precise chip formation.

Surface Finish Comparison

Abrasive machining typically delivers superior surface finishes due to the use of fine abrasive particles that produce micro-cutting action, resulting in smoother and more precise surfaces. Single point cutting often leaves tool marks and a rougher texture, especially on harder materials, as it relies on a single cutting edge removing material in larger chips. Surface roughness values in abrasive machining can reach below 0.1 micrometers Ra, while single point cutting generally achieves around 0.8 to 1.6 micrometers Ra, highlighting the advantage of abrasive methods in applications demanding high-quality finishes.

Tool Wear and Life

Abrasive machining typically generates higher tool wear due to the abrasive particles causing continuous micro-cutting and fracture, resulting in shorter tool life compared to single point cutting, where tool wear predominantly occurs through gradual flank and crater wear. Single point cutting tools benefit from controlled contact with the workpiece, often allowing for longer operational life under optimized cutting conditions, whereas abrasive machining tools require frequent dressing or replacement to maintain effectiveness. Monitoring thermal and mechanical stresses is crucial in both processes to extend tool life and ensure consistent surface finish quality.

Process Efficiency and Productivity

Abrasive machining delivers higher process efficiency by enabling simultaneous material removal across numerous micro-cutting points, significantly reducing cycle times compared to single point cutting, which relies on one cutting edge per operation. Productivity in abrasive machining is enhanced through continuous cutting action and better heat dissipation, resulting in prolonged tool life and consistent surface finish quality. Single point cutting maintains precision in shaping complex geometries but typically requires slower feed rates and more frequent tool changes, limiting overall throughput.

Applications in Manufacturing

Abrasive machining is ideal for producing complex shapes, fine surface finishes, and hard materials such as ceramics and hardened steels often found in aerospace and automotive components. Single point cutting excels in turning operations for shaping metals like aluminum and steel, commonly used in manufacturing shafts, rods, and engine parts. Both processes are crucial in manufacturing, with abrasive machining enhancing precision and surface quality, while single point cutting offers efficiency in material removal and shaping.

Advantages and Limitations

Abrasive machining excels in shaping hard and brittle materials with high precision, offering superior surface finish and minimal thermal damage compared to single point cutting. However, it often has slower material removal rates and increased tool wear, leading to higher operational costs. Single point cutting provides faster material removal and simpler tool geometry but is less effective for hard materials and can cause greater surface damage and tool deflection.

Selection Criteria for Machining Processes

Selection criteria for abrasive machining versus single point cutting depend on material hardness, required surface finish, and dimensional accuracy. Abrasive machining is preferred for hard, brittle materials and applications needing fine surface finishes or tight tolerances, while single point cutting suits softer materials and operations emphasizing high material removal rates. Considerations also include tool wear resistance, production speed, and cost-efficiency for optimal process choice.

Abrasive machining Infographic

libterm.com

libterm.com