The LVDT (Linear Variable Differential Transformer) is a precise electromagnetic sensor widely used for measuring linear displacement with high accuracy and reliability. Its robust design ensures consistent performance in various industrial applications, making it ideal for position sensing tasks. Discover how the LVDT can enhance your measurement accuracy by exploring the detailed insights in the following article.

Table of Comparison

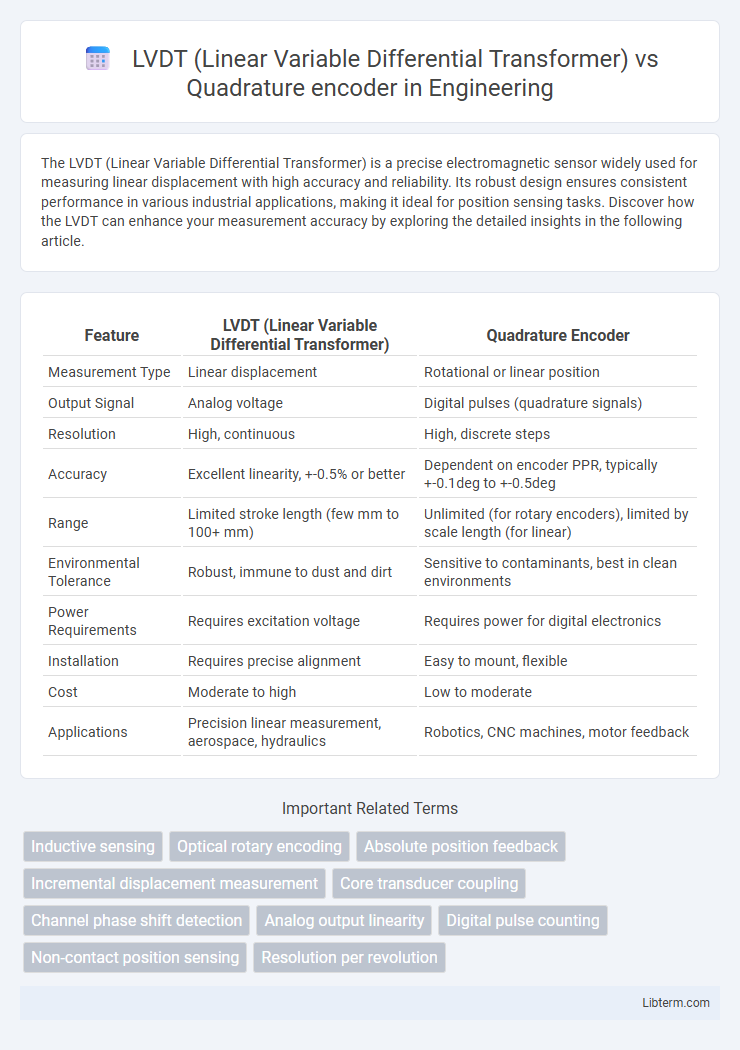

| Feature | LVDT (Linear Variable Differential Transformer) | Quadrature Encoder |

|---|---|---|

| Measurement Type | Linear displacement | Rotational or linear position |

| Output Signal | Analog voltage | Digital pulses (quadrature signals) |

| Resolution | High, continuous | High, discrete steps |

| Accuracy | Excellent linearity, +-0.5% or better | Dependent on encoder PPR, typically +-0.1deg to +-0.5deg |

| Range | Limited stroke length (few mm to 100+ mm) | Unlimited (for rotary encoders), limited by scale length (for linear) |

| Environmental Tolerance | Robust, immune to dust and dirt | Sensitive to contaminants, best in clean environments |

| Power Requirements | Requires excitation voltage | Requires power for digital electronics |

| Installation | Requires precise alignment | Easy to mount, flexible |

| Cost | Moderate to high | Low to moderate |

| Applications | Precision linear measurement, aerospace, hydraulics | Robotics, CNC machines, motor feedback |

Introduction to LVDT and Quadrature Encoder

LVDT (Linear Variable Differential Transformer) is an electromechanical sensor that measures linear displacement with high accuracy and repeatability by converting mechanical motion into an electrical signal. Quadrature encoders provide precise angular position and speed feedback using two offset digital signals, enabling direction detection and incremental position tracking. Both devices are essential in industrial automation, with LVDTs excelling in linear measurement applications and quadrature encoders widely used for rotational position sensing.

Operating Principles of LVDT

LVDTs operate based on the principle of electromagnetic induction, where a movable ferromagnetic core inside a coil assembly alters the mutual inductance between primary and secondary coils to produce a differential voltage proportional to linear displacement. This contactless sensing mechanism ensures high-resolution, frictionless measurements with excellent repeatability and durability. Unlike quadrature encoders that use optical or magnetic pulses to detect rotational position, LVDTs provide direct analog output for precise linear position sensing in harsh environments.

Working Mechanism of Quadrature Encoder

Quadrature encoders operate by converting the angular position or motion of a shaft into two pulse signals, A and B, which are phase-shifted by 90 degrees, allowing precise detection of direction and speed. These signals are produced via optoelectronic sensors reading a rotating disk with alternating transparent and opaque segments, enabling high-resolution position feedback. Unlike the inductive coupling in LVDTs, quadrature encoders rely on optical or magnetic sensing, providing digital output useful for incremental position measurement in motion control systems.

Key Differences between LVDT and Quadrature Encoder

LVDTs provide contactless, analog displacement measurements with high accuracy and resolution over short linear ranges, offering excellent repeatability and robustness in harsh environments. Quadrature encoders deliver digital position feedback with precise incremental counts and direction detection, ideal for rotary or linear motion control requiring absolute position information. The primary difference lies in LVDT's continuous analog output for linear displacement versus quadrature encoder's discrete digital pulses suited for incremental position tracking.

Accuracy and Resolution Comparison

LVDT sensors offer high accuracy with typical linearity errors less than 0.25% of full scale, making them ideal for precise displacement measurements in harsh environments. Quadrature encoders provide excellent resolution, often reaching sub-micron levels depending on the encoder's pole count and electronics, but their accuracy depends on mechanical alignment and can be affected by backlash or noise. Comparing both, LVDTs excel in absolute accuracy and robustness, while quadrature encoders offer superior resolution for incremental position tracking.

Application Areas: Where to Use LVDT vs Quadrature Encoder

LVDTs excel in applications requiring precise, contactless linear displacement measurement with high resolution and reliability, such as aerospace testing, hydraulic cylinder position sensing, and material testing machines. Quadrature encoders are ideal for measuring rotational position and speed in industrial automation, robotics, CNC machinery, and servo motor feedback systems due to their capability to provide accurate angular position and direction. Selection depends on the measurement type--linear displacement favors LVDTs, while rotational or angular position measurement suits quadrature encoders.

Advantages of LVDT Sensors

LVDT sensors offer highly accurate and repeatable linear position measurements with exceptional resolution and reliability in harsh environments, making them ideal for industrial and aerospace applications. Their frictionless operation ensures minimal wear and extended lifespan compared to quadrature encoders, which rely on mechanical components subject to degradation. LVDTs also provide inherent robustness against dust, moisture, and temperature variations, outperforming quadrature encoders in terms of durability and maintenance requirements.

Benefits of Quadrature Encoders

Quadrature encoders offer high-resolution position feedback with precise angular and linear displacement measurement, making them ideal for dynamic motion control systems. Their digital output enables easy integration with microcontrollers and PLCs, enhancing signal reliability and noise immunity compared to LVDTs. Furthermore, quadrature encoders provide direct velocity and direction information, reducing the need for additional sensors and simplifying system design.

Limitations and Challenges

LVDTs face limitations including sensitivity to electromagnetic interference, limited frequency response, and the need for precise alignment and calibration to maintain accuracy. Quadrature encoders encounter challenges such as signal noise at high speeds, wear and tear in mechanical components, and difficulty in providing absolute position without additional sensors or initialization. Both devices require careful environmental considerations to ensure reliable and precise motion measurement in industrial applications.

Choosing Between LVDT and Quadrature Encoder

Choosing between an LVDT and a quadrature encoder depends on the application requirements for precision and type of measurement; LVDTs provide highly accurate and contactless linear displacement measurement with excellent repeatability and robustness in harsh environments. Quadrature encoders excel in measuring rotational position and speed with digital output, ideal for applications requiring precise angular displacement and velocity feedback. Consider factors such as linear vs. rotary motion, required resolution, environmental conditions, and signal processing needs when selecting the optimal sensor type.

LVDT (Linear Variable Differential Transformer) Infographic

libterm.com

libterm.com