Thermoelectric refrigeration uses the Peltier effect to transfer heat between two materials, creating a cooling effect without moving parts or refrigerants. This technology offers energy efficiency, compact design, and silent operation, making it ideal for small-scale cooling applications like portable coolers and electronic device cooling. Explore the rest of the article to discover how thermoelectric refrigeration can enhance your cooling solutions.

Table of Comparison

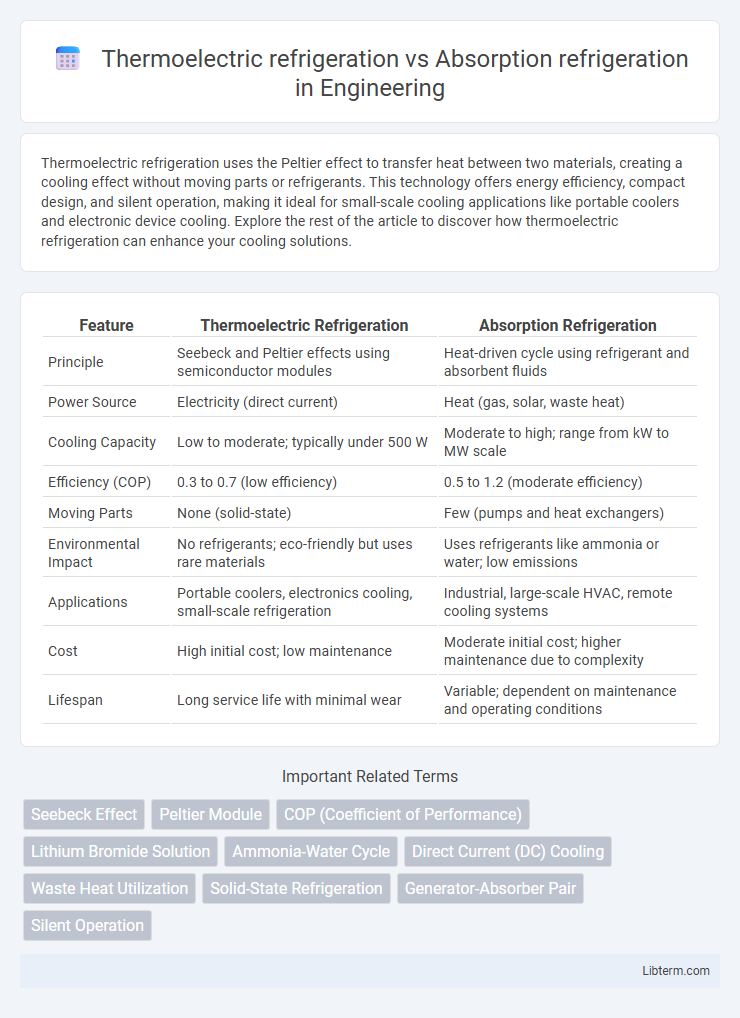

| Feature | Thermoelectric Refrigeration | Absorption Refrigeration |

|---|---|---|

| Principle | Seebeck and Peltier effects using semiconductor modules | Heat-driven cycle using refrigerant and absorbent fluids |

| Power Source | Electricity (direct current) | Heat (gas, solar, waste heat) |

| Cooling Capacity | Low to moderate; typically under 500 W | Moderate to high; range from kW to MW scale |

| Efficiency (COP) | 0.3 to 0.7 (low efficiency) | 0.5 to 1.2 (moderate efficiency) |

| Moving Parts | None (solid-state) | Few (pumps and heat exchangers) |

| Environmental Impact | No refrigerants; eco-friendly but uses rare materials | Uses refrigerants like ammonia or water; low emissions |

| Applications | Portable coolers, electronics cooling, small-scale refrigeration | Industrial, large-scale HVAC, remote cooling systems |

| Cost | High initial cost; low maintenance | Moderate initial cost; higher maintenance due to complexity |

| Lifespan | Long service life with minimal wear | Variable; dependent on maintenance and operating conditions |

Introduction to Thermoelectric and Absorption Refrigeration

Thermoelectric refrigeration utilizes the Peltier effect to create a temperature difference by transferring heat between two materials when an electric current passes through them, enabling solid-state cooling without moving parts or refrigerants. Absorption refrigeration relies on a heat source to drive a cycle involving a refrigerant and an absorbent, typically ammonia and water or lithium bromide and water, allowing cooling with minimal electrical input often used in industrial and large-scale applications. Both technologies offer distinct advantages in energy efficiency and environmental impact, with thermoelectric systems favored for compact, portable cooling and absorption systems suited for continuous, low-maintenance operation.

Basic Working Principles

Thermoelectric refrigeration operates based on the Peltier effect, where an electric current passes through a junction of two different conductors, creating a temperature difference that absorbs heat on one side and releases it on the other. Absorption refrigeration relies on a heat source to drive the refrigeration cycle, using a refrigerant-absorbent pair, typically ammonia-water or lithium bromide-water, to create cooling through evaporation and absorption processes. Both systems convert thermal energy into cooling, but thermoelectric refrigeration uses solid-state electronics while absorption refrigeration uses thermochemical processes involving fluid circulation.

Key Components and Materials

Thermoelectric refrigeration utilizes semiconductor materials such as bismuth telluride to create a Peltier effect through solid-state thermoelectric modules, eliminating moving parts and refrigerants. Absorption refrigeration relies on a heat source to drive a cycle involving key components like the generator, absorber, condenser, and evaporator, typically using ammonia-water or lithium bromide-water solutions as working fluids. The material choice in thermoelectric systems emphasizes high electrical conductivity and low thermal conductivity, while absorption systems depend on chemical compatibility and thermal stability of the absorbent-refrigerant pair.

Energy Efficiency Comparison

Thermoelectric refrigeration systems typically exhibit lower energy efficiency, with coefficients of performance (COP) around 0.3 to 0.5, compared to absorption refrigeration units which can achieve COP values between 0.6 and 1.2 under similar operating conditions. Thermoelectric devices convert electrical energy directly into a heat flux using semiconductor materials, resulting in higher energy losses, whereas absorption refrigeration relies on heat sources such as natural gas or waste heat, enhancing overall system efficiency. The choice between thermoelectric and absorption refrigeration often hinges on specific application needs, where absorption refrigeration offers superior energy performance especially in continuous cooling environments.

Environmental Impact Assessment

Thermoelectric refrigeration systems use solid-state components that generate minimal greenhouse gas emissions, avoiding harmful refrigerants and reducing ozone depletion potential. Absorption refrigeration relies on ammonia, lithium bromide, or water as refrigerants, which can pose environmental risks if leaked, but often utilize waste heat or renewable energy sources, enhancing sustainability. Life cycle assessments indicate thermoelectric units have lower direct emissions, whereas absorption systems may offer better overall energy efficiency and reduced carbon footprint when powered by renewable heat.

Cooling Performance and Reliability

Thermoelectric refrigeration offers precise temperature control and solid-state reliability with no moving parts, making it ideal for small-scale cooling applications, though its cooling performance is limited by lower efficiency and heat dissipation challenges. Absorption refrigeration delivers higher cooling capacity and energy efficiency for larger systems by utilizing heat sources like natural gas or solar energy, but it relies on complex components such as generators and absorbers, which can increase maintenance demands. Reliability in thermoelectric units excels due to minimal mechanical wear, while absorption systems require regular upkeep to maintain optimal performance and prevent component degradation.

Cost Analysis and Maintenance

Thermoelectric refrigeration systems typically have higher upfront costs due to expensive semiconductor materials but benefit from low maintenance requirements, lacking moving parts and refrigerants. Absorption refrigeration units often incur lower initial costs but demand higher ongoing maintenance expenses, including regular checks for leaks, fluid refills, and component replacements. Cost analysis should factor in the long-term operational expenses, where thermoelectric models may offer savings through reduced maintenance, while absorption systems could require more frequent servicing and part replacements.

Practical Applications and Use Cases

Thermoelectric refrigeration excels in compact, portable applications such as cooling electronic devices, medical storage units, and small beverage coolers due to its solid-state operation and precise temperature control. Absorption refrigeration is widely used in large-scale, off-grid systems like RV air conditioning, solar-powered cooling, and industrial refrigeration where waste heat or renewable energy sources are available. Both technologies cater to niche markets: thermoelectric units offer silent, vibration-free cooling with minimal maintenance, while absorption systems provide eco-friendly options with low electrical consumption in remote or sustainable environments.

Advantages and Limitations

Thermoelectric refrigeration offers advantages such as compact size, silent operation, and precise temperature control due to solid-state components, making it ideal for small-scale applications. However, its limitations include low cooling efficiency and higher power consumption compared to traditional methods. Absorption refrigeration benefits from using waste heat or renewable energy sources, providing environmentally friendly and energy-efficient cooling with minimal moving parts, but it requires a continuous heat supply and typically involves larger, more complex systems.

Future Trends in Refrigeration Technologies

Thermoelectric refrigeration is gaining momentum due to advancements in semiconductor materials enhancing efficiency and durability, promoting eco-friendly, vibration-free cooling suitable for niche applications. Absorption refrigeration benefits from breakthroughs in alternative heat sources, such as solar thermal energy, improving sustainability and enabling deployment in off-grid or low-energy environments. Future trends emphasize hybrid systems integrating both technologies to optimize energy use, reduce greenhouse gas emissions, and accommodate evolving climate control demands.

Thermoelectric refrigeration Infographic

libterm.com

libterm.com