A brazed joint offers a strong, leak-proof connection by joining metals through a filler metal with a lower melting point. This technique provides excellent mechanical strength and corrosion resistance, making it ideal for applications in HVAC, plumbing, and automotive industries. Explore the rest of this article to understand how brazed joints can enhance the reliability of your metal assemblies.

Table of Comparison

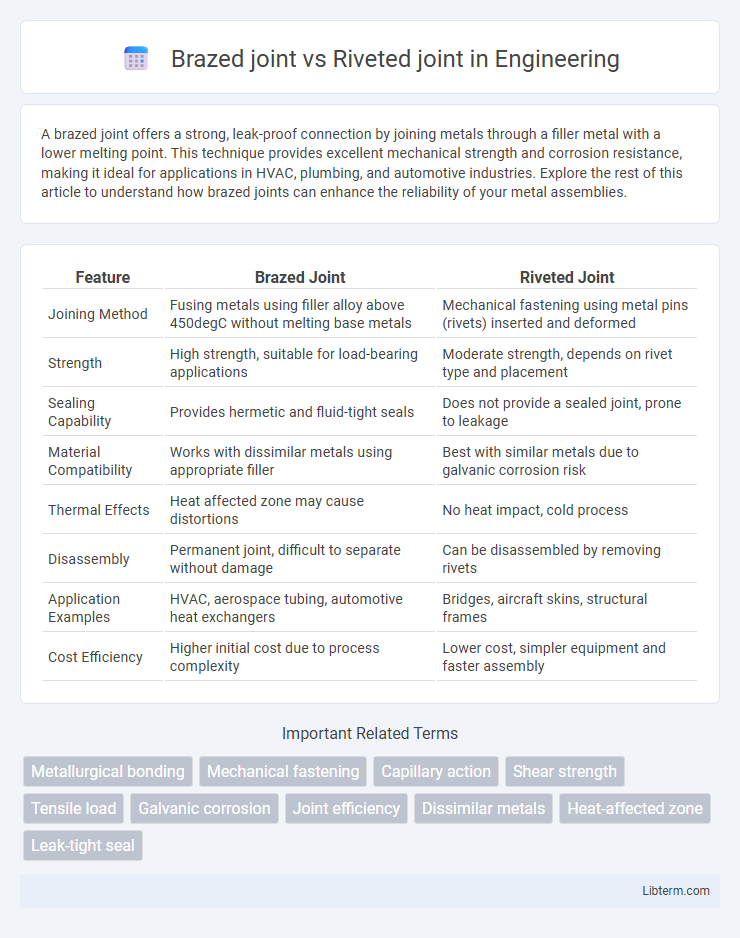

| Feature | Brazed Joint | Riveted Joint |

|---|---|---|

| Joining Method | Fusing metals using filler alloy above 450degC without melting base metals | Mechanical fastening using metal pins (rivets) inserted and deformed |

| Strength | High strength, suitable for load-bearing applications | Moderate strength, depends on rivet type and placement |

| Sealing Capability | Provides hermetic and fluid-tight seals | Does not provide a sealed joint, prone to leakage |

| Material Compatibility | Works with dissimilar metals using appropriate filler | Best with similar metals due to galvanic corrosion risk |

| Thermal Effects | Heat affected zone may cause distortions | No heat impact, cold process |

| Disassembly | Permanent joint, difficult to separate without damage | Can be disassembled by removing rivets |

| Application Examples | HVAC, aerospace tubing, automotive heat exchangers | Bridges, aircraft skins, structural frames |

| Cost Efficiency | Higher initial cost due to process complexity | Lower cost, simpler equipment and faster assembly |

Introduction to Brazed and Riveted Joints

Brazed joints create strong, leak-proof connections by melting a filler metal between closely fitted base metals without melting the base materials, commonly used in HVAC and automotive industries. Riveted joints join metal sheets using metal pins or rivets, providing durable mechanical fastening typically found in structural applications such as bridges and aircraft. Both methods offer distinct mechanical and thermal properties tailored for specific engineering requirements and load conditions.

Definition and Working Principle

Brazed joints join metal parts by melting a filler metal with a lower melting point than the base metals, creating a strong, leak-proof bond upon cooling without melting the workpieces themselves. Riveted joints mechanically fasten components together using metal pins or bolts inserted through aligned holes, which are then deformed or secured by a nut to provide a durable and removable connection. The brazing process relies on capillary action and diffusion to bond metals, while riveting depends on plastic deformation to maintain structural integrity.

Material Compatibility

Brazed joints offer superior material compatibility by allowing the joining of dissimilar metals such as copper, stainless steel, and aluminum due to the use of filler metals with lower melting points. Riveted joints primarily require similar or compatible materials to ensure mechanical strength and avoid galvanic corrosion, limiting their use in mixed-material assemblies. This makes brazing preferable for applications demanding high strength and corrosion resistance across varied metal types.

Strength and Durability Comparison

Brazed joints offer superior strength due to the metallurgical bond formed between the base metals and filler material, resulting in high load-bearing capacity and resistance to fatigue. Riveted joints rely on mechanical fastening, which may introduce stress concentrations and potential loosening under dynamic loads, reducing overall durability. Consequently, brazed joints provide enhanced long-term performance in applications requiring strong, leak-tight, and corrosion-resistant connections.

Design Flexibility

Brazed joints offer greater design flexibility by allowing the joining of dissimilar metals and complex shapes with minimal distortion due to lower processing temperatures compared to welding. Riveted joints provide strong mechanical fastening but are limited by hole placement and the inability to connect intricate or thin-walled components without compromising structural integrity. The choice between brazed and riveted joints depends heavily on the complexity of the design and material compatibility requirements.

Manufacturing Process Differences

Brazed joints use a filler metal with a melting point above 450degC, which flows into the joint by capillary action without melting the base metals, requiring precise temperature control and clean surfaces during the heating process. Riveted joints involve mechanically fastening two or more components using metal pins, where the rivets are hammered or pressed to form a secure clamping force, demanding accurate hole alignment and manual or automated riveting equipment. The brazing process typically requires controlled heating cycles in furnaces or torches, making it suitable for complex or delicate assemblies, whereas riveting is faster and often used for structural joins in aerospace or automotive manufacturing where disassembly is not necessary.

Cost Considerations

Brazed joints typically incur higher initial costs due to the requirement for specialized equipment and skilled labor, but they offer superior strength and leak-proof sealing which can reduce long-term maintenance expenses. Riveted joints have lower upfront costs with simple tools and faster assembly, ideal for budget-conscious projects, but may require regular inspection and tightening, increasing lifecycle costs. Cost effectiveness depends on application-specific factors such as load requirements, environmental exposure, and maintenance capabilities.

Applications in Industry

Brazed joints are widely used in HVAC systems, automotive radiators, and aerospace components due to their excellent strength, airtightness, and corrosion resistance. Riveted joints remain popular in structural applications like bridges, aircraft fuselages, and heavy machinery where mechanical fastening and ease of assembly are critical. The choice between brazed and riveted joints depends on factors such as load requirements, environmental exposure, and production volume in industrial settings.

Advantages and Disadvantages

Brazed joints offer superior strength and airtight sealing compared to riveted joints, making them ideal for applications requiring corrosion resistance and high thermal conductivity. However, brazing requires precise temperature control and specialized equipment, potentially increasing manufacturing costs. Riveted joints provide easier assembly and disassembly with good mechanical fastening but are prone to stress concentration and less effective in fluid-tight applications.

Selection Criteria and Recommendations

Brazed joints offer superior strength and corrosion resistance, making them ideal for applications requiring airtight or watertight seals, especially in thin-walled or dissimilar metal assemblies. Riveted joints provide greater mechanical reliability under dynamic loads and are preferred in structures where ease of inspection and maintenance is critical, such as in aerospace and heavy machinery. Selection should prioritize operating environment, load conditions, and material compatibility to optimize joint performance and longevity.

Brazed joint Infographic

libterm.com

libterm.com