Electroactive polymers (EAPs) are smart materials that change shape or size when stimulated by an electric field, making them ideal for applications in sensors, actuators, and artificial muscles. Their lightweight, flexible properties provide significant advantages for developing innovative technologies in robotics and biomedical devices. Explore the full article to discover how electroactive polymers could transform your next project.

Table of Comparison

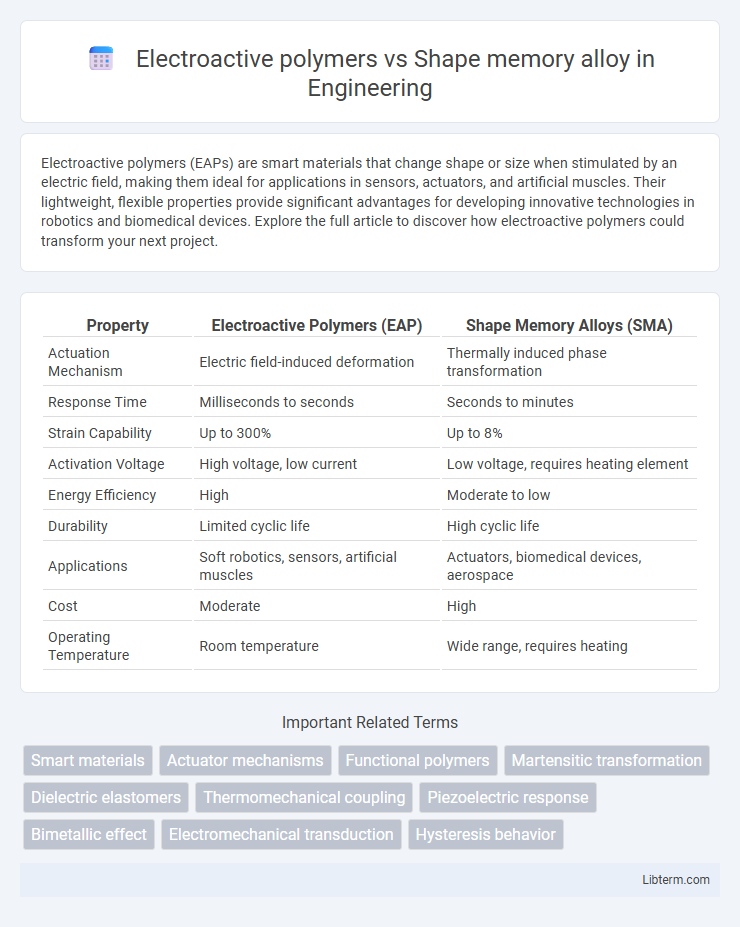

| Property | Electroactive Polymers (EAP) | Shape Memory Alloys (SMA) |

|---|---|---|

| Actuation Mechanism | Electric field-induced deformation | Thermally induced phase transformation |

| Response Time | Milliseconds to seconds | Seconds to minutes |

| Strain Capability | Up to 300% | Up to 8% |

| Activation Voltage | High voltage, low current | Low voltage, requires heating element |

| Energy Efficiency | High | Moderate to low |

| Durability | Limited cyclic life | High cyclic life |

| Applications | Soft robotics, sensors, artificial muscles | Actuators, biomedical devices, aerospace |

| Cost | Moderate | High |

| Operating Temperature | Room temperature | Wide range, requires heating |

Introduction to Electroactive Polymers and Shape Memory Alloys

Electroactive polymers (EAPs) are flexible materials capable of reversible shape changes under electrical stimulation, making them ideal for soft robotics and adaptive systems. Shape memory alloys (SMAs) are metal alloys that undergo phase transformations to recover their original shape when heated, widely used in actuators and medical devices. Both EAPs and SMAs exhibit unique electro-mechanical properties crucial for smart material applications, with EAPs offering higher strain capabilities and SMAs providing greater force output.

Fundamental Principles and Material Properties

Electroactive polymers (EAPs) operate through ion migration or electronic charge displacement, enabling large, flexible deformations under electric fields, whereas shape memory alloys (SMAs) exhibit phase transformations between martensite and austenite phases that produce reversible shape changes upon thermal or mechanical stimuli. EAPs are lightweight, have high strain capabilities exceeding 100%, and respond rapidly to voltage, making them suitable for applications requiring flexibility and low power consumption. In contrast, SMAs possess high mechanical strength, durability, and exhibit shape recovery strains typically between 4-8%, with slower response times dominated by thermal activation, favoring use in load-bearing actuators and structural applications.

Actuation Mechanisms: How EAPs and SMAs Work

Electroactive Polymers (EAPs) actuate through the deformation of polymer chains in response to an electric field, causing bending, stretching, or contraction due to ionic or electronic mobility within the material. Shape Memory Alloys (SMAs) function by undergoing a reversible phase transformation between martensite and austenite phases, enabling shape recovery driven by temperature changes or applied stress. The actuation of EAPs offers high flexibility and rapid response at low voltages, whereas SMAs provide significant force output and shape memory effects controlled thermally.

Comparison of Response Speed and Efficiency

Electroactive polymers (EAPs) demonstrate faster response speeds, typically in the range of milliseconds to seconds, due to their lightweight and flexible molecular structure, making them ideal for rapid actuation in soft robotics and adaptive systems. Shape memory alloys (SMAs) generally exhibit slower response times, often from seconds to minutes, as their actuation depends on phase transformation induced by temperature changes, resulting in higher energy consumption and thermal inefficiency. EAPs excel in energy efficiency with low voltage operation and minimal heat generation, whereas SMAs require significant thermal input, leading to energy loss and slower cooling cycles that limit their overall actuation speed and efficiency.

Mechanical Strength and Durability Analysis

Electroactive polymers (EAPs) exhibit moderate mechanical strength with high flexibility, making them suitable for applications requiring lightweight and deformable materials, while shape memory alloys (SMAs) demonstrate superior mechanical strength and durability through their ability to withstand cyclic loading and recover large strains without permanent deformation. SMAs typically outperform EAPs in fatigue resistance and long-term durability due to their metallic crystal structure, enabling sustained performance in high-stress environments. Mechanical strength of SMAs ranges from 600 to 1,200 MPa with consistent durability over millions of cycles, whereas EAPs generally possess lower tensile strengths (10-100 MPa) and may degrade under prolonged mechanical stress and environmental exposure.

Design Flexibility and Application Versatility

Electroactive polymers (EAPs) offer exceptional design flexibility due to their lightweight, compliant nature and ability to undergo large strains, making them ideal for soft robotics, biomedical devices, and adaptive optics. Shape memory alloys (SMAs) provide high actuation force and predictable shape recovery but are limited by stiffness and slower response times, restricting their application in delicate or intricately shaped components. EAPs excel in applications requiring customizable, stretchable actuators, while SMAs are preferred for robust, load-bearing tasks where material strength is critical.

Energy Consumption and Power Requirements

Electroactive polymers (EAPs) consume significantly less energy compared to shape memory alloys (SMAs) due to their low voltage operation and high efficiency in converting electrical input into mechanical displacement. SMAs require substantial power input to induce phase transformation, often resulting in higher energy consumption and slower response times. The power requirements of EAPs make them ideal for applications demanding lightweight, low-energy actuation, whereas SMAs are favored in scenarios needing high force but at the expense of increased energy usage.

Key Applications: Robotics, Medical Devices, and More

Electroactive polymers (EAPs) and shape memory alloys (SMAs) are pivotal in robotics and medical devices, where EAPs excel in soft robotics due to their flexibility, lightweight nature, and rapid response times, enabling precise movements and adaptive grips. SMAs, characterized by their high force output and temperature-driven shape changes, are widely used in minimally invasive surgical tools, stents, and actuators requiring high strength and durability. Both materials extend to aerospace and wearable technologies, with EAPs favored for silent operation and SMAs for robust mechanical performance.

Cost, Scalability, and Manufacturing Challenges

Electroactive polymers (EAPs) generally offer lower material costs and simpler fabrication processes compared to shape memory alloys (SMAs), which require expensive metal alloys and precision manufacturing techniques. EAPs benefit from scalability due to their polymeric nature, enabling easier mass production through established polymer processing methods like molding and extrusion, while SMAs face challenges scaling up because of complex heat treatments and alloy composition control. Manufacturing challenges for EAPs involve ensuring consistent actuation performance and durability, whereas SMAs require precise control over phase transformation and fatigue resistance, increasing overall production complexity and costs.

Future Trends and Innovations in Smart Material Technologies

Electroactive polymers (EAPs) and shape memory alloys (SMAs) are pivotal in the evolution of smart material technologies, with future trends emphasizing enhanced durability, energy efficiency, and integration with artificial intelligence for adaptive responses. Innovations are steering towards hybrid systems combining EAPs' flexibility and SMAs' strength to develop responsive actuators and sensors in soft robotics and biomedical devices. Advances in nanoscale fabrication and material science are expected to drive breakthroughs in responsiveness and multifunctionality, solidifying their roles in next-generation wearable technology and autonomous systems.

Electroactive polymers Infographic

libterm.com

libterm.com