Hybrid relay technology combines the strengths of both amplify-and-forward and decode-and-forward relays to enhance communication reliability and efficiency in wireless networks. It dynamically adapts to varying channel conditions, optimizing the transmission process to reduce errors and improve signal quality. Explore the rest of the article to understand how hybrid relays can transform your network performance.

Table of Comparison

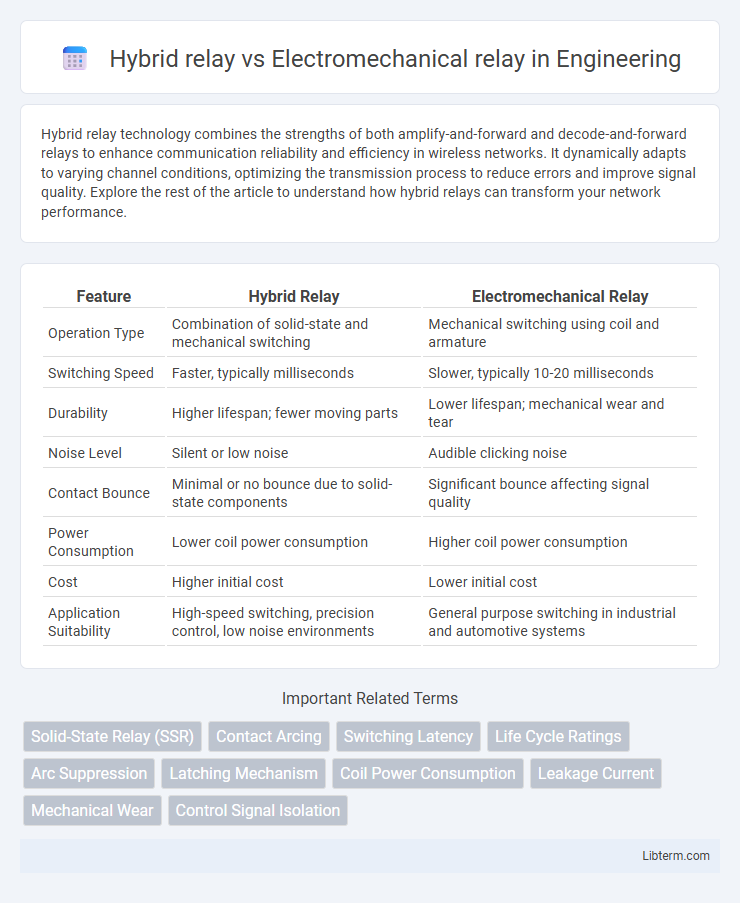

| Feature | Hybrid Relay | Electromechanical Relay |

|---|---|---|

| Operation Type | Combination of solid-state and mechanical switching | Mechanical switching using coil and armature |

| Switching Speed | Faster, typically milliseconds | Slower, typically 10-20 milliseconds |

| Durability | Higher lifespan; fewer moving parts | Lower lifespan; mechanical wear and tear |

| Noise Level | Silent or low noise | Audible clicking noise |

| Contact Bounce | Minimal or no bounce due to solid-state components | Significant bounce affecting signal quality |

| Power Consumption | Lower coil power consumption | Higher coil power consumption |

| Cost | Higher initial cost | Lower initial cost |

| Application Suitability | High-speed switching, precision control, low noise environments | General purpose switching in industrial and automotive systems |

Introduction to Relay Technologies

Hybrid relays combine the fast switching capabilities of solid-state relays with the high current capacity and reliability of electromechanical relays, offering enhanced performance in industrial automation and control systems. Electromechanical relays operate through physical contacts and electromagnets, providing reliable switching for high-power applications but with slower response times and mechanical wear concerns. Choosing between hybrid and electromechanical relay technologies depends on application requirements such as switching speed, load type, and durability.

Overview of Electromechanical Relays

Electromechanical relays operate using an electromagnetic coil to mechanically switch contacts, providing electrical isolation and reliable switching for high-current loads. These relays are known for their simplicity, durability, and ability to handle large voltages and currents in applications such as industrial controls and automotive systems. Despite slower switching speeds compared to solid-state and hybrid relays, electromechanical relays remain popular due to their robust performance and cost-effectiveness.

What Are Hybrid Relays?

Hybrid relays combine the advantages of both solid-state and electromechanical relays by integrating semiconductor components with mechanical contacts, offering rapid switching speeds and high reliability. They provide extended lifespan and reduced contact wear compared to traditional electromechanical relays, making them suitable for applications requiring frequent switching and high endurance. Hybrid relays maintain electrical isolation and low power consumption while delivering faster response times and minimal electromagnetic interference.

Key Differences Between Hybrid and Electromechanical Relays

Hybrid relays combine solid-state and electromechanical components, offering faster switching times and longer operational life compared to traditional electromechanical relays, which rely solely on mechanical contacts. Electromechanical relays typically provide higher current ratings and better isolation but suffer from contact wear and slower response. Key differences include switching speed, durability, noise level, and maintenance requirements, with hybrid relays excelling in performance-critical and low-maintenance applications.

Performance and Response Time Comparison

Hybrid relays combine the fast switching speed of solid-state components with the high current capacity of electromechanical contacts, resulting in superior performance and reduced contact wear compared to traditional electromechanical relays. Electromechanical relays typically exhibit response times in the range of 5 to 15 milliseconds, whereas hybrid relays can achieve faster response times, often below 1 millisecond, due to the semiconductor switching elements. The enhanced response time and reliability of hybrid relays make them ideal for applications requiring rapid switching and high durability under frequent operation conditions.

Reliability and Longevity Analysis

Hybrid relays combine the mechanical durability of electromechanical relays with solid-state technology, resulting in improved reliability and extended longevity compared to traditional electromechanical relays. Electromechanical relays often suffer from contact wear and mechanical fatigue, limiting their operational lifespan, whereas hybrid relays reduce these issues by minimizing contact arcing and mechanical stress. As a result, hybrid relays typically offer higher cycle endurance and enhanced performance in demanding industrial applications requiring consistent switching reliability.

Energy Efficiency and Power Consumption

Hybrid relays consume significantly less power than electromechanical relays due to their combination of solid-state electronics and mechanical contacts, which reduces energy loss during switching. Electromechanical relays typically require continuous coil current to maintain their state, resulting in higher power consumption and lower energy efficiency. The energy-saving advantage of hybrid relays makes them ideal for applications demanding long operational life and reduced electrical consumption.

Applications: Where Each Relay Excels

Hybrid relays excel in high-frequency switching applications such as telecommunications and precision measurement systems due to their fast response time and low contact wear. Electromechanical relays are preferred in industrial and automotive settings where high voltage and current handling, robustness, and mechanical isolation are critical. Both relay types offer distinct advantages, with hybrid relays optimizing speed and longevity and electromechanical relays ensuring durability and high power capacity.

Cost Implications and Maintenance Needs

Hybrid relays typically offer lower operational costs due to reduced contact wear and longer lifespan compared to electromechanical relays, which require frequent replacements and higher maintenance efforts. Electromechanical relays incur ongoing expenses from mechanical parts prone to degradation and contact corrosion, increasing downtime and repair costs. Investing in hybrid relays can minimize maintenance needs and total cost of ownership despite a higher initial purchase price.

Choosing the Right Relay: Factors to Consider

Selecting the right relay depends on factors such as switching speed, reliability, and load type. Hybrid relays offer faster switching times and longer lifespan due to solid-state components, making them ideal for applications requiring high-speed operation and reduced wear. Electromechanical relays provide robust performance for high-power loads and are preferable when cost and simple switching are primary concerns.

Hybrid relay Infographic

libterm.com

libterm.com