Yield strength represents the maximum stress a material can withstand without permanent deformation, making it a crucial factor in engineering and construction. Understanding yield strength helps you select appropriate materials for safety and durability in various applications. Explore the rest of the article to learn how yield strength impacts material performance and design choices.

Table of Comparison

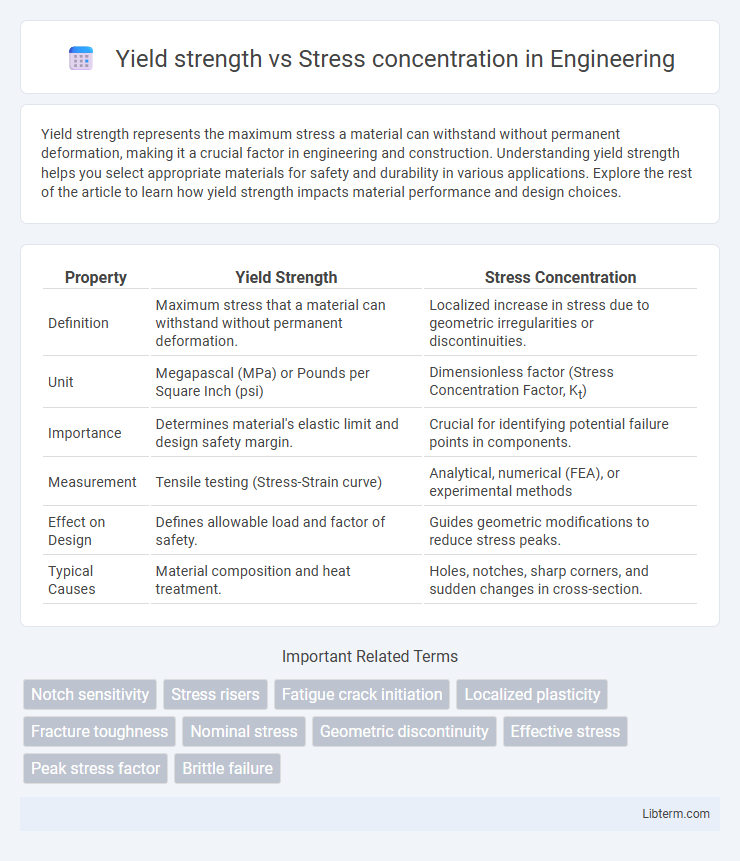

| Property | Yield Strength | Stress Concentration |

|---|---|---|

| Definition | Maximum stress that a material can withstand without permanent deformation. | Localized increase in stress due to geometric irregularities or discontinuities. |

| Unit | Megapascal (MPa) or Pounds per Square Inch (psi) | Dimensionless factor (Stress Concentration Factor, Kt) |

| Importance | Determines material's elastic limit and design safety margin. | Crucial for identifying potential failure points in components. |

| Measurement | Tensile testing (Stress-Strain curve) | Analytical, numerical (FEA), or experimental methods |

| Effect on Design | Defines allowable load and factor of safety. | Guides geometric modifications to reduce stress peaks. |

| Typical Causes | Material composition and heat treatment. | Holes, notches, sharp corners, and sudden changes in cross-section. |

Introduction to Yield Strength and Stress Concentration

Yield strength defines the maximum stress a material can endure without permanent deformation, marking the transition from elastic to plastic behavior. Stress concentration refers to localized increases in stress near flaws, notches, or geometric discontinuities, which can significantly reduce the effective yield strength of a component. Understanding the interplay between yield strength and stress concentration is essential for designing materials and structures that resist failure under complex loading conditions.

Defining Yield Strength in Materials

Yield strength in materials is the critical stress level at which a material begins to deform plastically, marking the transition from elastic to permanent deformation. Stress concentration refers to localized increases in stress within a material, often caused by geometric discontinuities like notches or holes, which can significantly reduce the effective yield strength in those regions. Understanding the interplay between yield strength and stress concentration is essential for predicting material failure and ensuring structural integrity under load.

Understanding Stress Concentration

Stress concentration occurs at points of geometric discontinuity such as holes, notches, or sharp corners, causing localized increases in stress that exceed the material's yield strength. These amplified stresses can initiate yielding or failure even when the nominal stress is below the yield limit, making accurate prediction of stress concentration factors essential for structural integrity. Understanding the relationship between yield strength and stress concentration allows engineers to design components that avoid premature failure by reinforcing critical areas or selecting materials with higher yield strengths.

Causes and Effects of Stress Concentration

Stress concentration arises from geometric discontinuities such as notches, holes, or sharp corners, which amplify local stress beyond the nominal yield strength of a material. This localized increase in stress often leads to premature yielding or failure even when the overall applied stress is below the uniform yield strength, reducing component reliability and lifespan. Understanding and mitigating stress concentration effects are critical for accurate yield strength assessments and ensuring structural integrity in engineering designs.

Yield Strength vs Stress Concentration: Key Differences

Yield strength defines the maximum stress a material can withstand without permanent deformation, while stress concentration refers to localized stress intensifications around geometric discontinuities such as notches or holes. The presence of stress concentration can significantly reduce the effective yield strength in those regions, leading to premature failure compared to the nominal yield strength of the material. Understanding the interplay between yield strength and stress concentration is crucial for designing components that maintain structural integrity under real-world loading conditions.

Factors Affecting Yield Strength and Stress Concentration

Yield strength is significantly influenced by material composition, grain size, temperature, and strain rate, which determine its ability to withstand plastic deformation. Stress concentration arises mainly from geometric discontinuities such as notches, holes, and sharp corners that amplify local stresses beyond the nominal stress levels. The interaction between yield strength and stress concentration factors dictates the initiation of yielding and potential failure in structural components under load.

Methods to Measure Yield Strength

Yield strength measurement techniques such as tensile testing and instrumented indentation provide critical data to evaluate material performance under stress concentration. Digital image correlation and strain gauge methods enhance accuracy by capturing localized deformation near stress concentrators like notches or holes. These advanced measurement methods allow engineers to predict failure and optimize designs by correlating yield strength with varying stress concentration factors.

Techniques to Minimize Stress Concentration

Yield strength determines a material's ability to withstand applied stress without permanent deformation, while stress concentration refers to localized stress exceeding the average stress, often occurring near geometric discontinuities. Techniques to minimize stress concentration include implementing fillets or smooth transitions at sharp corners, using notch treatments like shot peening to introduce compressive residual stresses, and designing with uniform cross-sections to distribute stress evenly. Optimizing these methods enhances the effective yield strength by reducing the risk of premature yielding or failure at critical stress concentrators.

Real-World Examples: Yield Strength and Stress Concentration

Yield strength determines the maximum stress a material can withstand without permanent deformation, while stress concentration occurs at geometric discontinuities causing localized stress to exceed this limit. In aircraft fuselage design, sharp corners or holes create stress concentrations that can reduce the effective yield strength and lead to crack initiation under cyclic loading. Engineers use fillets and material selection with higher yield strength to mitigate these effects, ensuring structural integrity in real-world applications.

Conclusion: Balancing Yield Strength and Stress Concentration in Design

Balancing yield strength and stress concentration is critical to ensuring structural integrity and durability in engineering designs. High yield strength materials can withstand greater applied loads but may be more susceptible to failure if stress concentrations are not properly managed through geometric optimization or material selection. Effective design strategies integrate yield strength assessments with stress concentration factors to prevent premature yielding and enhance overall component performance.

Yield strength Infographic

libterm.com

libterm.com