Reliability-centered maintenance focuses on prioritizing maintenance tasks based on the criticality and failure modes of equipment to maximize operational efficiency and minimize downtime. This strategic approach helps identify the most effective maintenance strategies, ensuring your assets perform reliably and cost-effectively. Explore the rest of the article to discover how implementing reliability-centered maintenance can transform your maintenance practices.

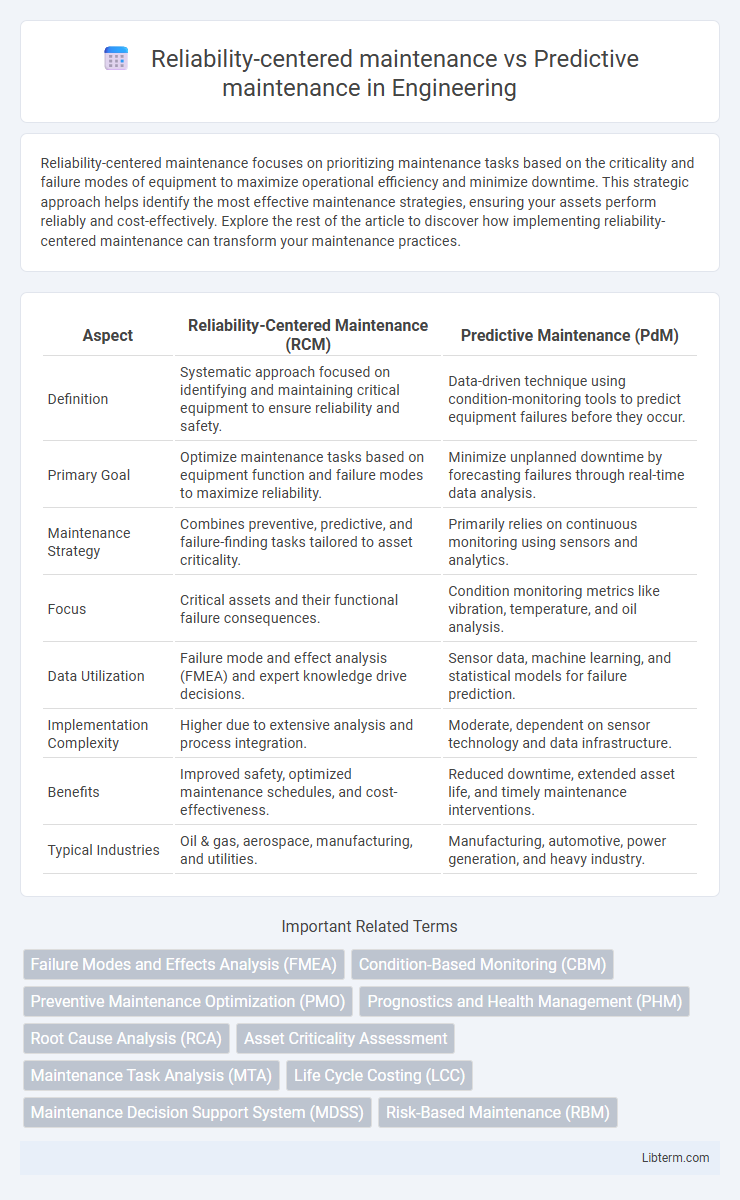

Table of Comparison

| Aspect | Reliability-Centered Maintenance (RCM) | Predictive Maintenance (PdM) |

|---|---|---|

| Definition | Systematic approach focused on identifying and maintaining critical equipment to ensure reliability and safety. | Data-driven technique using condition-monitoring tools to predict equipment failures before they occur. |

| Primary Goal | Optimize maintenance tasks based on equipment function and failure modes to maximize reliability. | Minimize unplanned downtime by forecasting failures through real-time data analysis. |

| Maintenance Strategy | Combines preventive, predictive, and failure-finding tasks tailored to asset criticality. | Primarily relies on continuous monitoring using sensors and analytics. |

| Focus | Critical assets and their functional failure consequences. | Condition monitoring metrics like vibration, temperature, and oil analysis. |

| Data Utilization | Failure mode and effect analysis (FMEA) and expert knowledge drive decisions. | Sensor data, machine learning, and statistical models for failure prediction. |

| Implementation Complexity | Higher due to extensive analysis and process integration. | Moderate, dependent on sensor technology and data infrastructure. |

| Benefits | Improved safety, optimized maintenance schedules, and cost-effectiveness. | Reduced downtime, extended asset life, and timely maintenance interventions. |

| Typical Industries | Oil & gas, aerospace, manufacturing, and utilities. | Manufacturing, automotive, power generation, and heavy industry. |

Introduction to Maintenance Strategies

Reliability-centered maintenance (RCM) prioritizes identifying critical equipment functions and failure modes to develop tailored maintenance plans that maximize system reliability and safety. Predictive maintenance (PdM) uses real-time data and advanced analytics to monitor equipment condition, allowing timely interventions before failures occur and minimizing downtime. Both strategies aim to optimize maintenance efficiency but differ in their approach: RCM is function-driven and failure-focused, while PdM is data-driven and condition-based.

What is Reliability-Centered Maintenance (RCM)?

Reliability-Centered Maintenance (RCM) is a structured framework used to determine the most effective maintenance strategies based on the reliability and criticality of equipment functions. It prioritizes maintenance tasks by analyzing failure modes, their effects, and consequences to optimize asset performance and reduce downtime. Unlike Predictive Maintenance, which relies on condition-monitoring technologies to predict failures, RCM integrates both preventive and predictive approaches to ensure equipment reliability and safety.

Understanding Predictive Maintenance (PdM)

Predictive Maintenance (PdM) leverages real-time data, sensor analytics, and machine learning algorithms to forecast equipment failures before they occur, optimizing maintenance schedules and minimizing unplanned downtime. Unlike Reliability-Centered Maintenance (RCM), which emphasizes systematic analysis of failure modes and effects to prioritize maintenance tasks, PdM focuses on condition monitoring and trend analysis for precise, data-driven interventions. This approach enhances asset lifespan and operational efficiency by targeting maintenance efforts only when measurable indicators suggest an impending failure.

Core Principles of RCM

Reliability-centered maintenance (RCM) emphasizes identifying and prioritizing maintenance activities based on the functions and potential failure modes of assets to ensure operational reliability and safety. Core principles of RCM include failure mode and effects analysis (FMEA), prioritization of maintenance tasks based on risk assessment, and the selection of appropriate proactive maintenance strategies such as preventive, predictive, or condition-based maintenance. In contrast, predictive maintenance primarily relies on real-time condition monitoring and data analytics to forecast failures and optimize maintenance schedules without the comprehensive failure mode evaluation inherent in RCM.

Key Features of Predictive Maintenance

Predictive maintenance leverages real-time data through sensors and advanced analytics to forecast equipment failures before they occur, increasing operational efficiency and reducing downtime. Key features include condition monitoring, vibration analysis, and machine learning algorithms that interpret historical and current asset performance data. This approach contrasts with reliability-centered maintenance by emphasizing proactive intervention based on precise diagnostics rather than scheduled maintenance tasks.

Benefits of RCM versus Predictive Maintenance

Reliability-centered maintenance (RCM) prioritizes critical assets and systematically identifies failure modes to tailor maintenance strategies that maximize equipment reliability and safety, leading to reduced downtime and optimized resource allocation. In contrast, predictive maintenance relies heavily on real-time condition monitoring data, which may require significant sensor investment and may not address all failure scenarios comprehensively. RCM's structured approach provides a holistic framework that enhances decision-making and ensures maintenance efforts focus on actions that effectively mitigate risks and improve long-term asset performance.

Challenges and Limitations: RCM and PdM

Reliability-centered maintenance (RCM) faces challenges including complex implementation processes and the need for extensive system knowledge to accurately determine failure modes and maintenance priorities. Predictive maintenance (PdM) limitations often arise from data quality issues, sensor reliability, and the high cost of advanced analytics and equipment integration. Both approaches require skilled personnel and continuous updating of models to remain effective in dynamic industrial environments.

Implementation Process: RCM vs. PdM

The implementation process of Reliability-Centered Maintenance (RCM) involves a detailed analysis of asset functions, failure modes, and consequences to develop customized maintenance strategies that prioritize system reliability. Predictive Maintenance (PdM) implementation relies on continuous condition monitoring technologies--such as vibration analysis, infrared thermography, and oil particle counting--to anticipate equipment failures and schedule maintenance proactively. RCM requires structured decision-making and failure mode impact assessment, whereas PdM depends on real-time data acquisition and predictive analytics for timely intervention.

Cost Considerations and ROI Analysis

Reliability-centered maintenance (RCM) focuses on prioritizing maintenance tasks based on asset criticality, often requiring detailed analysis and upfront costs for implementation, but can optimize long-term cost efficiency by preventing catastrophic failures. Predictive maintenance (PdM) leverages real-time data and condition-monitoring technologies, resulting in higher initial investment in sensors and analytics while aiming to reduce unplanned downtime and maintenance expenses. ROI analysis typically shows that RCM provides strategic value in high-risk environments with critical assets, whereas PdM delivers faster payback in industries with abundant data and recurring operational demands.

Choosing the Right Strategy for Your Organization

Reliability-centered maintenance (RCM) and predictive maintenance (PdM) serve distinct roles in asset management strategies, with RCM emphasizing the identification of critical assets and failure modes to optimize maintenance tasks, while PdM uses real-time data and condition monitoring to predict failures before they occur. Choosing the right strategy involves assessing organizational priorities, asset criticality, available technology, and maintenance resources, ensuring alignment with overall operational goals and cost-efficiency. Organizations with complex, high-value assets often benefit from integrating RCM's structured approach with PdM's data-driven insights to maximize uptime and reduce maintenance costs.

Reliability-centered maintenance Infographic

libterm.com

libterm.com