Maintaining proper face contact is crucial for effective communication, as it conveys confidence and attentiveness while fostering trust. Understanding the nuances of eye contact, facial expressions, and gestures can significantly enhance your interpersonal skills in both personal and professional settings. Explore the rest of this article to discover how mastering face contact can improve your connections and influence.

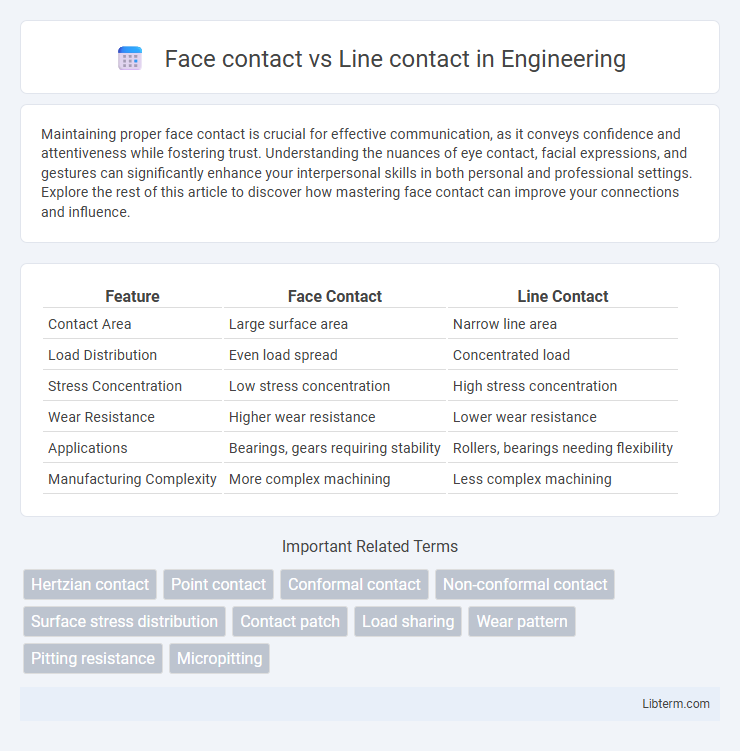

Table of Comparison

| Feature | Face Contact | Line Contact |

|---|---|---|

| Contact Area | Large surface area | Narrow line area |

| Load Distribution | Even load spread | Concentrated load |

| Stress Concentration | Low stress concentration | High stress concentration |

| Wear Resistance | Higher wear resistance | Lower wear resistance |

| Applications | Bearings, gears requiring stability | Rollers, bearings needing flexibility |

| Manufacturing Complexity | More complex machining | Less complex machining |

Introduction to Face Contact and Line Contact

Face contact involves the contact between the entire flat surfaces of two mating components, distributing the load over a larger area, which reduces stress and wear. Line contact occurs when the contact is along a single line or narrow edge, concentrating forces and often resulting in higher contact stress. Understanding the differences in load distribution and stress concentration is essential for selecting appropriate bearings, gears, or mechanical joints in engineering applications.

Defining Face Contact in Engineering

Face contact in engineering refers to the interaction where two surfaces come into contact over an entire face or area rather than along a narrow line. This type of contact typically distributes load more evenly, reducing stress concentrations and wear, which is critical in gear teeth, bearings, and sealing surfaces. Face contact is essential for ensuring structural integrity in components subjected to compressive forces and for optimizing mechanical performance in assemblies requiring precise alignment.

Understanding Line Contact Mechanics

Line contact mechanics involve the interaction of two surfaces in contact along a line rather than an area, leading to concentrated stress distribution ideal for cylindrical or curved elements like rollers and cam followers. The Hertzian contact theory often models these stresses, predicting contact width and pressure that influence fatigue life and wear resistance. Understanding line contact is crucial for optimizing bearing design and ensuring reliable performance under high load and dynamic conditions.

Key Differences Between Face and Line Contact

Face contact occurs when two surfaces meet over an entire area, distributing load uniformly and providing greater stability, commonly seen in flat or cylindrical joints. Line contact involves two surfaces touching along a line, concentrating stress and often found in cylindrical or conical bearings, allowing for easier alignment but less load distribution. The key differences between face and line contact lie in the contact area, stress distribution, and typical applications, with face contact offering higher load-bearing capacity and line contact facilitating rotational motion.

Material Considerations for Contact Types

Face contact typically involves a larger surface area, leading to lower contact stress and improved load distribution, which is beneficial for materials with lower hardness and higher ductility such as brass or bronze. Line contact concentrates stress along a narrow region, requiring materials with higher hardness and wear resistance, like hardened steel or ceramics, to prevent deformation and surface fatigue. Selecting appropriate materials based on contact type ensures optimal durability and performance in mechanical components.

Load Distribution in Face vs Line Contact

Face contact provides a larger surface area, resulting in more uniform load distribution and reduced stress concentration compared to line contact. Line contact confines the load to a narrow area, increasing the risk of higher localized stresses and potential material deformation. Optimal load distribution in face contact enhances durability and performance in applications such as gear teeth or bearing interfaces.

Applications and Use Cases

Face contact bearings provide higher load capacity and stiffness, making them ideal for heavy-duty machinery and industrial equipment requiring precise alignment and shock absorption. Line contact bearings offer lower friction and better speed capabilities, commonly used in high-speed applications such as electric motors, aerospace components, and precision instruments. Choosing between face and line contact depends on specific application demands including load type, speed, and alignment accuracy.

Impact on Wear and Durability

Face contact distributes load over a larger surface area, resulting in lower contact stress and reduced wear rates, which enhances durability in mechanical components such as bearings and gears. Line contact, by concentrating load along a narrow line, experiences higher localized stress, increasing the risk of surface fatigue and accelerated wear, thereby decreasing component lifespan. Optimizing contact type according to application requirements is crucial to balance performance demands and extend service life.

Performance Comparison and Efficiency

Face contact bearings distribute loads over a larger surface area, resulting in higher load capacity and improved shock absorption compared to line contact bearings, which concentrate stresses along a narrow contact line. Line contact bearings typically exhibit lower frictional losses and higher rotational speed capabilities due to reduced contact surface, enhancing overall efficiency in high-speed applications. In performance-critical environments, face contact designs excel in durability and load handling, while line contact options prioritize energy efficiency and speed.

Conclusion: Choosing the Right Contact Type

Face contact bearings provide larger contact areas, resulting in better load distribution and higher load capacity, ideal for heavy-duty applications. Line contact bearings offer lower friction and greater precision, making them suitable for high-speed and precision machinery. Selecting the right contact type depends on load requirements, speed, and precision needs, with face contact favored for durability and line contact for accuracy.

Face contact Infographic

libterm.com

libterm.com