Binder jetting is an innovative 3D printing technique that uses a liquid binding agent to selectively join powder particles layer by layer, producing complex parts with high speed and efficiency. This process allows for the creation of metal, ceramic, or sand components with excellent surface finish and minimal post-processing. Discover how binder jetting can revolutionize your manufacturing capabilities by reading the full article.

Table of Comparison

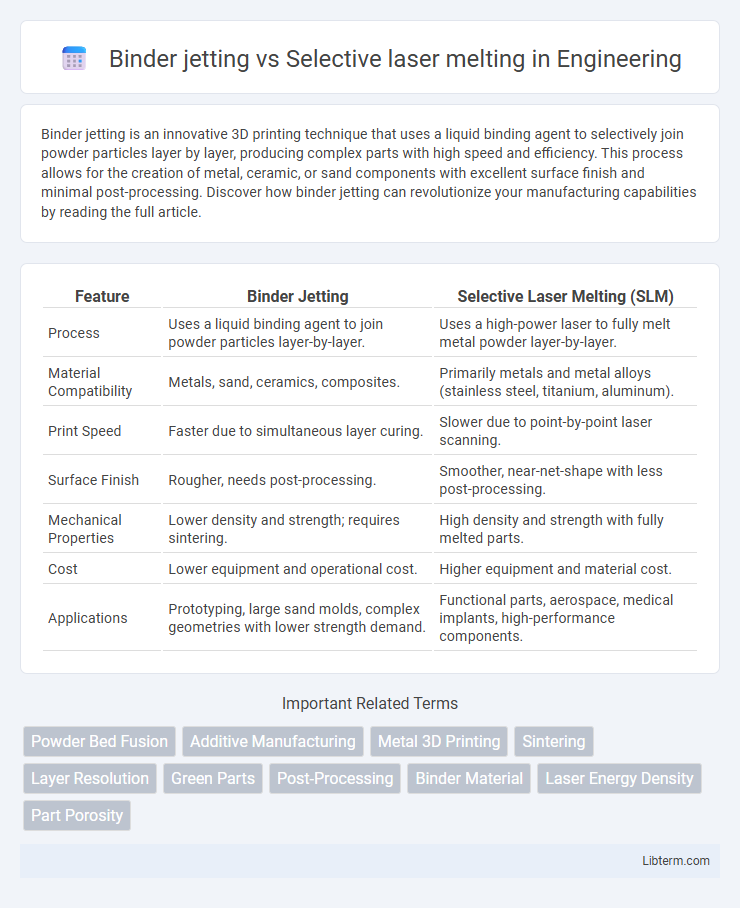

| Feature | Binder Jetting | Selective Laser Melting (SLM) |

|---|---|---|

| Process | Uses a liquid binding agent to join powder particles layer-by-layer. | Uses a high-power laser to fully melt metal powder layer-by-layer. |

| Material Compatibility | Metals, sand, ceramics, composites. | Primarily metals and metal alloys (stainless steel, titanium, aluminum). |

| Print Speed | Faster due to simultaneous layer curing. | Slower due to point-by-point laser scanning. |

| Surface Finish | Rougher, needs post-processing. | Smoother, near-net-shape with less post-processing. |

| Mechanical Properties | Lower density and strength; requires sintering. | High density and strength with fully melted parts. |

| Cost | Lower equipment and operational cost. | Higher equipment and material cost. |

| Applications | Prototyping, large sand molds, complex geometries with lower strength demand. | Functional parts, aerospace, medical implants, high-performance components. |

Introduction to Binder Jetting and Selective Laser Melting

Binder Jetting utilizes a liquid binding agent selectively deposited onto a powder bed, enabling faster printing speeds and reduced thermal distortion compared to Selective Laser Melting (SLM). Selective Laser Melting employs a high-powered laser to fully melt metal powders layer by layer, producing dense, high-strength parts suitable for complex geometries and aerospace or medical applications. The choice between Binder Jetting and SLM depends on factors like desired material properties, production speed, surface finish, and post-processing requirements.

Technology Overview: How Binder Jetting Works

Binder jetting involves depositing a liquid binding agent onto a thin layer of powdered material, selectively bonding particles to form solid sections layer by layer without using heat. A roller or blade spreads a fresh powder layer over the build platform after each binding pass, enabling rapid production of complex geometries. Unlike Selective Laser Melting, which fuses powdered metal using a high-powered laser, binder jetting operates at room temperature, reducing residual stresses and allowing for a broader range of materials.

Technology Overview: How Selective Laser Melting Works

Selective Laser Melting (SLM) utilizes a high-powered laser beam to selectively melt and fuse metallic powder particles layer by layer, creating dense and complex metal parts with superior mechanical properties. The process begins with a thin layer of metal powder spread across the build platform, followed by the laser precisely scanning and melting the powder according to the 3D CAD data. SLM achieves full melting and metallurgical bonding, resulting in parts with high strength, fine microstructure, and excellent surface finish compared to Binder Jetting, which relies on binder agents and post-processing sintering.

Material Compatibility: Binder Jetting vs SLM

Binder jetting supports a wide range of materials including metals, ceramics, and composites due to its layer-by-layer powder bonding process without melting, allowing for greater material versatility and lower thermal stresses. Selective laser melting (SLM) primarily works with metal powders such as stainless steel, titanium, aluminum, and nickel alloys, relying on high-powered lasers to fully melt the particles and create dense, strong parts. The fundamental difference in material compatibility arises from binder jetting's ability to process temperature-sensitive and brittle materials versus SLM's requirement for highly fusionable metal powders capable of withstanding intense laser energy.

Part Quality and Surface Finish Comparison

Binder jetting produces parts with moderate surface finish characterized by a slightly rough texture due to powder agglomeration, typically requiring post-processing to achieve finer details. Selective laser melting (SLM) delivers superior part quality with higher density and resolution, resulting in smoother surfaces and enhanced mechanical properties directly from the build. The layer fusion mechanism in SLM minimizes porosity, whereas binder jetting's reliance on binder infiltration often leads to increased surface porosity and dimensional inaccuracies.

Speed and Production Efficiency Analysis

Binder jetting offers faster production speeds due to its layer-by-layer deposition without the need for high-temperature melting, enabling rapid fabrication of large, complex parts with minimal thermal distortion. Selective laser melting (SLM) involves intricate laser scanning to fully melt metal powders, resulting in slower build rates but superior mechanical properties and density. While binder jetting excels in high-volume, cost-effective manufacturing, SLM prioritizes precision and part integrity at the expense of production speed.

Cost Factors: Binder Jetting vs SLM

Binder jetting generally offers lower initial equipment costs and faster production speeds, making it more cost-effective for large-scale, less complex parts. Selective laser melting (SLM) incurs higher expenses due to specialized laser technology, slower build rates, and elevated energy consumption, increasing overall production costs. Material costs for SLM are also higher, as it requires high-purity metal powders with tight specifications, whereas binder jetting can utilize a broader range of materials at lower expenses.

Typical Applications and Industries

Binder jetting excels in producing complex metal and ceramic parts with cost-effective, high-volume manufacturing, commonly used in aerospace for lightweight components and automotive for prototyping and casting molds. Selective laser melting (SLM) offers superior mechanical properties and precision, making it ideal for aerospace, medical implants, and high-performance engineering parts requiring intricate geometries and functionality. Both technologies serve the industrial sector but diverge with binder jetting optimizing speed and volume, whereas SLM prioritizes strength and detail in aerospace, automotive, healthcare, and tooling industries.

Advantages and Limitations of Each Process

Binder jetting offers advantages such as faster build speeds, lower energy consumption, and the ability to produce large, complex parts without residual stresses or warping, making it ideal for sand casting molds and metal parts with moderate strength requirements. Limitations include lower mechanical properties, reduced density, and the need for post-processing like sintering or infiltration to achieve full part strength. Selective laser melting provides superior part density, excellent mechanical properties, and the capability to produce fully dense, complex metal components with fine detail but is slower, more expensive, and requires higher energy input, with potential thermal distortion and residual stress challenges.

Choosing the Right Technology for Your Needs

Binder jetting offers faster production speeds and lower material costs, making it ideal for large-scale, less complex parts and prototypes, while selective laser melting (SLM) provides superior mechanical properties and intricate detail suitable for high-performance, functional components. Assessing factors such as required part strength, surface finish, build volume, and budget helps determine the optimal technology for your specific application. Selecting the right additive manufacturing process ensures efficient production and meets performance requirements effectively.

Binder jetting Infographic

libterm.com

libterm.com