Sliding fit provides a precise yet movable connection between mating parts, ensuring smooth relative motion without excessive looseness or tightness. This type of fit is commonly used in assemblies where parts must slide or rotate with minimal friction, such as shafts in bearings or guide rails. Explore the article to understand how sliding fits enhance mechanical performance and promote durability in your designs.

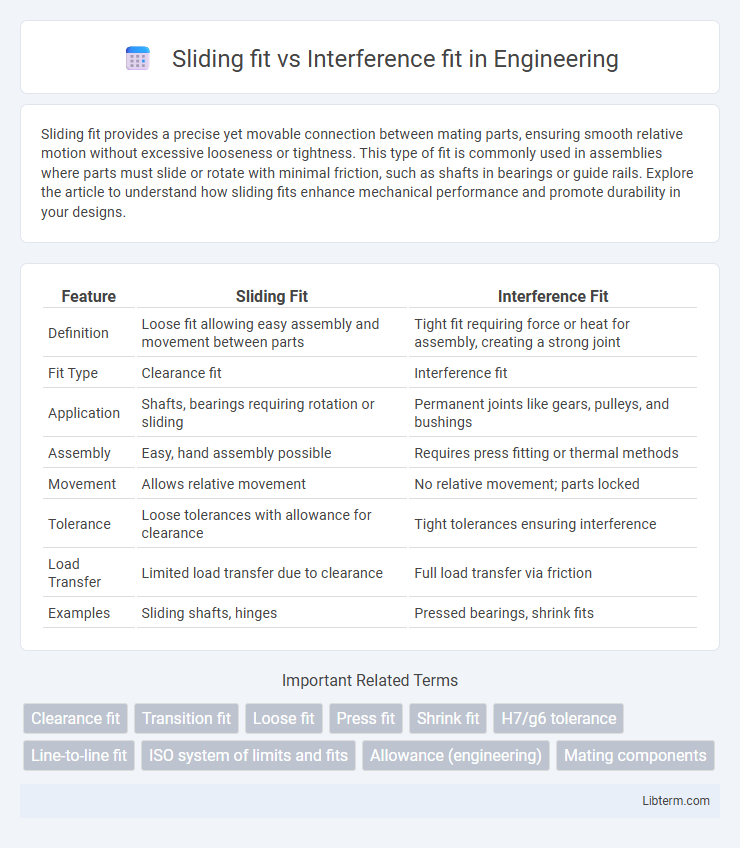

Table of Comparison

| Feature | Sliding Fit | Interference Fit |

|---|---|---|

| Definition | Loose fit allowing easy assembly and movement between parts | Tight fit requiring force or heat for assembly, creating a strong joint |

| Fit Type | Clearance fit | Interference fit |

| Application | Shafts, bearings requiring rotation or sliding | Permanent joints like gears, pulleys, and bushings |

| Assembly | Easy, hand assembly possible | Requires press fitting or thermal methods |

| Movement | Allows relative movement | No relative movement; parts locked |

| Tolerance | Loose tolerances with allowance for clearance | Tight tolerances ensuring interference |

| Load Transfer | Limited load transfer due to clearance | Full load transfer via friction |

| Examples | Sliding shafts, hinges | Pressed bearings, shrink fits |

Introduction to Sliding Fit and Interference Fit

Sliding fit allows two mating components to move or slide relative to each other with minimal clearance, ensuring easy assembly and smooth operation. Interference fit involves intentionally designed overlap between components, creating a tight joint requiring force or thermal methods for assembly to prevent movement. These fits are crucial in mechanical engineering for selecting appropriate tolerance levels based on functional requirements.

Defining Sliding Fit: Key Characteristics

Sliding fit, also known as a clearance fit, allows components to move freely with minimal friction, characterized by a small but intentional gap between mating parts. This fit ensures smooth relative motion, facilitating assembly and disassembly without force or deformation. Typical applications include bearings, shafts, and housings where ease of movement and alignment are critical.

Understanding Interference Fit: Essential Features

Interference fit involves assembling two parts with dimensions deliberately designed for a tight, pressure-induced connection, ensuring a secure and permanent joint. Key features include dimensional overlap where the shaft diameter slightly exceeds the hole diameter, causing material deformation and high frictional resistance that prevents relative movement. This fit is crucial in applications requiring high load transfer, precise alignment, and resistance to vibration without the need for additional fasteners.

Applications of Sliding Fit in Industry

Sliding fit is widely used in applications requiring easy assembly and disassembly, such as in bearings, shafts, and pulleys where parts must rotate or slide freely without excessive play. It ensures precise alignment and smooth motion in mechanical systems like conveyor belts, engine components, and machine tools, where minimal friction and wear are critical. Industries including automotive, aerospace, and manufacturing rely on sliding fit for components that demand reliable, repeatable movement under variable loads.

Typical Uses of Interference Fit

Interference fits are commonly used in applications requiring permanent or semi-permanent assembly, such as securing gears, pulleys, and bearings on shafts to prevent relative motion under high loads. They provide superior strength and stability in mechanical joints where precise alignment and resistance to vibration or torque are critical, often found in automotive engines, heavy machinery, and aerospace components. Sliding fits, in contrast, allow for easier assembly and disassembly, suiting parts that require frequent maintenance or movement.

Advantages of Sliding Fit

Sliding fit offers the advantage of easy assembly and disassembly due to its controlled clearance, minimizing wear and facilitating maintenance in mechanical components. This fit type allows for smooth relative motion between parts, reducing friction and enhancing operational efficiency in applications like shafts and bearings. Its tolerance for slight misalignments improves performance reliability and extends the lifespan of mating components.

Benefits of Interference Fit

Interference fit offers superior strength and stability by creating a permanent, rigid joint that resists loosening under dynamic loads and vibrations. This fit ensures precise alignment and load distribution, which enhances the durability and longevity of assembled components. It is ideal for high-stress applications where maintaining tight tolerances and preventing relative motion between parts is critical for performance.

Limitations of Sliding Fit

Sliding fit, characterized by clearances that allow easy assembly and movement between parts, faces limitations such as reduced load-carrying capacity and increased wear under heavy forces or high temperatures. The inherent clearance can lead to vibration, noise, and misalignment in precision applications, compromising performance and durability. Unlike interference fits, sliding fits lack the rigidity required for maintaining tight positional accuracy in dynamic environments.

Challenges Associated with Interference Fit

Interference fit presents challenges such as the requirement for precise dimensional control to avoid excessive stress during assembly, which can lead to component deformation or failure. The high force needed for installation demands specialized equipment and increases the risk of damage to parts or surroundings. Thermal expansion differences between materials must be carefully managed to maintain joint integrity under varying operating conditions.

Choosing Between Sliding Fit vs Interference Fit

Choosing between sliding fit and interference fit depends on the specific application requirements such as load, tolerance, and assembly conditions. Sliding fit allows easy movement and assembly with minimal resistance, ideal for parts needing frequent disassembly or alignment, while interference fit ensures strong, permanent joints that resist vibration and load through induced material deformation. Material properties, operating environment, and required precision also guide the selection process to achieve optimal performance and durability.

Sliding fit Infographic

libterm.com

libterm.com