Axial flow refers to the movement of fluid parallel to the axis of a rotating component, commonly found in turbines, compressors, and fans. This flow type is efficient for high-volume, low-pressure applications, optimizing energy transfer and minimizing losses within machinery. Discover how axial flow technology can enhance your system's performance by exploring the rest of this article.

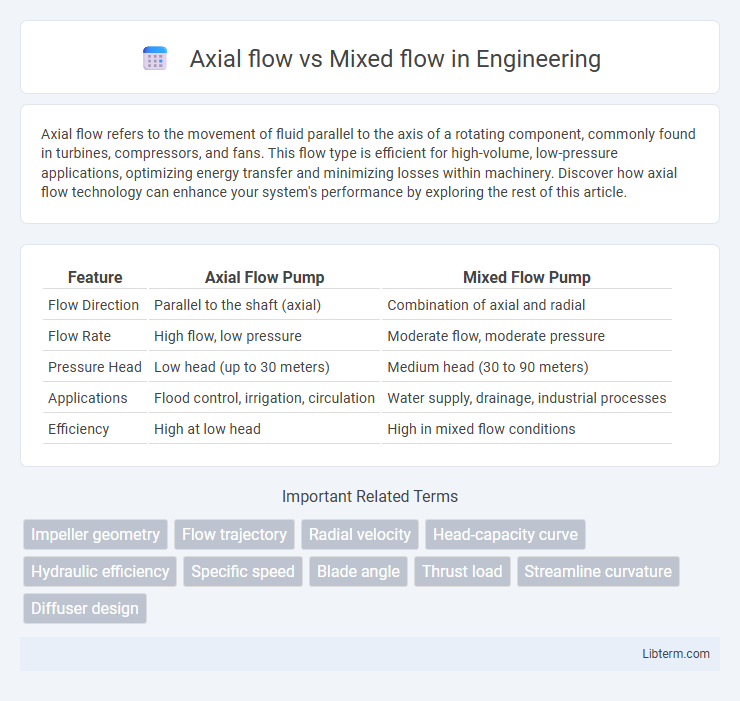

Table of Comparison

| Feature | Axial Flow Pump | Mixed Flow Pump |

|---|---|---|

| Flow Direction | Parallel to the shaft (axial) | Combination of axial and radial |

| Flow Rate | High flow, low pressure | Moderate flow, moderate pressure |

| Pressure Head | Low head (up to 30 meters) | Medium head (30 to 90 meters) |

| Applications | Flood control, irrigation, circulation | Water supply, drainage, industrial processes |

| Efficiency | High at low head | High in mixed flow conditions |

Introduction to Axial Flow and Mixed Flow

Axial flow fans move air parallel to the fan shaft, providing high volume with low pressure, making them ideal for ventilation and cooling applications. Mixed flow fans combine the features of axial and centrifugal fans, moving air both axially and radially to achieve higher pressure than axial fans while maintaining efficient airflow. These differences influence their use in HVAC systems, industrial processes, and aeration systems where specific pressure and flow requirements are critical.

Principles of Axial Flow Technology

Axial flow technology operates by moving fluid parallel to the rotating shaft, utilizing aerodynamic rotor blades designed to generate lift and thrust, resulting in efficient high-volume fluid transfer. The principle relies on maintaining consistent flow direction and pressure throughout the blade passage, minimizing energy losses and maximizing axial velocity components. This technology is commonly employed in applications requiring steady, high-flow rates such as ventilation systems, jet engines, and industrial compressors.

Fundamentals of Mixed Flow Technology

Mixed flow technology combines axial and centrifugal flow principles, directing fluid both axially and radially to achieve higher pressure at moderate flow rates. This design improves efficiency by optimizing blade geometry and flow path, leading to enhanced performance in pumps, compressors, and fans. Understanding the fundamental fluid dynamics behind mixed flow helps engineers tailor devices for applications requiring compact size and balanced pressure-flow characteristics.

Key Differences Between Axial Flow and Mixed Flow

Axial flow fans move air parallel to the impeller shaft, offering high volume flow rates with low pressure, ideal for ventilation and cooling applications. Mixed flow fans combine axial and centrifugal principles, delivering higher pressure than axial fans while maintaining efficient airflow, often used in HVAC systems requiring moderate pressure and flow. The primary difference lies in airflow direction and pressure capability, with axial fans favoring volume and mixed flow fans balancing pressure and flow efficiency.

Performance Comparison: Axial Flow vs Mixed Flow

Axial flow pumps deliver high flow rates at low to moderate pressures, making them ideal for applications requiring large volumes of fluid movement with low-head conditions. Mixed flow pumps combine axial and radial flow characteristics, providing a balance between flow rate and pressure, achieving higher heads than axial flow pumps while maintaining substantial flow capacities. Performance comparison highlights that axial flow pumps excel in high-volume, low-head scenarios, whereas mixed flow pumps offer versatile performance with improved pressure handling suitable for medium-head applications.

Applications of Axial Flow Systems

Axial flow systems are commonly used in applications requiring high flow rates with relatively low pressure, such as ventilation, air conditioning, and cooling towers. These fans are ideal for industrial processes, including power plants and wastewater treatment, where moving large volumes of air or gas efficiently is critical. Their ability to provide steady airflow with minimal energy consumption makes them suitable for aeration and exhaust systems.

Applications of Mixed Flow Systems

Mixed flow pumps are widely used in applications requiring moderate head and higher flow rates, such as irrigation, municipal water supply, and flood control systems. These systems efficiently handle varying flow conditions in stormwater management and cooling water circulation in power plants. Their ability to operate at intermediate pressure levels makes them ideal for fire-fighting and industrial process water applications.

Advantages and Limitations of Axial Flow

Axial flow fans offer high efficiency and low noise levels, making them ideal for ventilation in large industrial spaces and HVAC systems due to their ability to move large volumes of air with low pressure. They have a simple design that ensures ease of maintenance and lower manufacturing costs, supporting energy savings in long-term operations. However, axial flow fans are limited by their lower pressure capabilities, which restrict their use in applications requiring high static pressure, and their performance can decline significantly in dusty or corrosive environments without proper filtration.

Benefits and Drawbacks of Mixed Flow

Mixed flow pumps combine axial and radial flow characteristics, offering higher pressure capabilities than purely axial flow pumps, making them suitable for medium to high head applications. Their design provides efficient energy transfer and moderate flow rates, but they tend to be less efficient than axial flow pumps at very high flow volumes. Mixed flow pumps can require more maintenance due to complex impeller geometry and may have higher operational costs compared to axial flow models.

Choosing the Right Flow Type for Your Needs

Axial flow pumps excel in applications requiring high flow rates and low pressure, making them ideal for water circulation and flood control. Mixed flow pumps combine features of axial and radial designs, offering higher pressure and moderate flow, suitable for irrigation and industrial processes. Selecting between axial and mixed flow depends on the specific hydraulic requirements, such as flow volume, pressure head, and system efficiency.

Axial flow Infographic

libterm.com

libterm.com