Ultrasonication uses high-frequency sound waves to agitate particles in a solution, enhancing mixing, cleaning, or chemical reactions. This technology improves efficiency in processes like cell disruption, nanoparticle synthesis, and emulsification by creating cavitation bubbles. Explore the full article to discover how ultrasonication can optimize your applications and boost productivity.

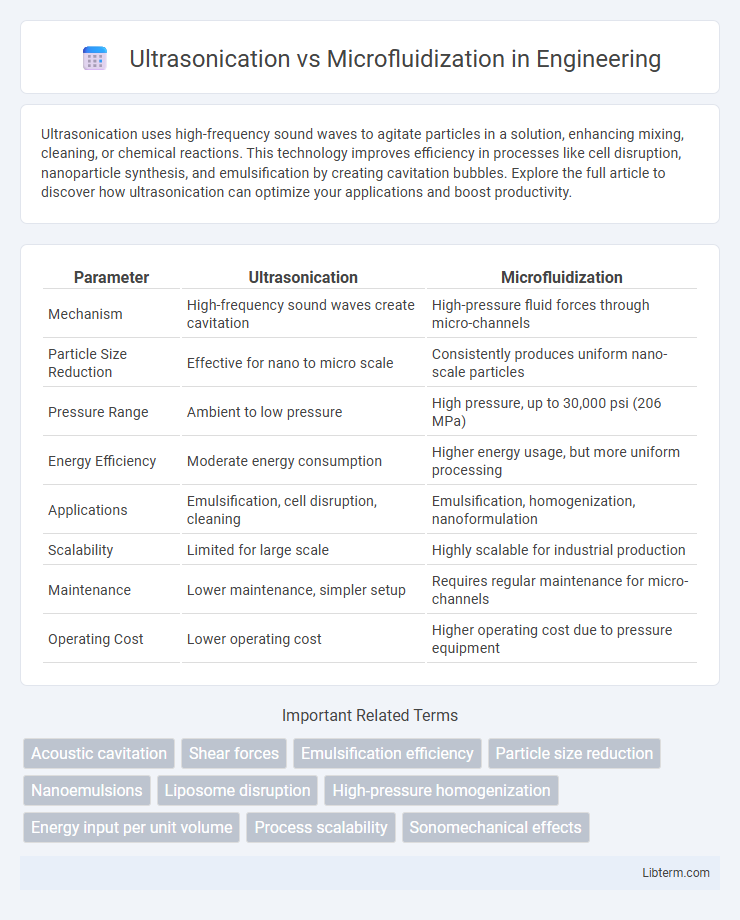

Table of Comparison

| Parameter | Ultrasonication | Microfluidization |

|---|---|---|

| Mechanism | High-frequency sound waves create cavitation | High-pressure fluid forces through micro-channels |

| Particle Size Reduction | Effective for nano to micro scale | Consistently produces uniform nano-scale particles |

| Pressure Range | Ambient to low pressure | High pressure, up to 30,000 psi (206 MPa) |

| Energy Efficiency | Moderate energy consumption | Higher energy usage, but more uniform processing |

| Applications | Emulsification, cell disruption, cleaning | Emulsification, homogenization, nanoformulation |

| Scalability | Limited for large scale | Highly scalable for industrial production |

| Maintenance | Lower maintenance, simpler setup | Requires regular maintenance for micro-channels |

| Operating Cost | Lower operating cost | Higher operating cost due to pressure equipment |

Introduction to Ultrasonication and Microfluidization

Ultrasonication utilizes high-frequency sound waves to generate cavitation bubbles in liquids, leading to intense shear forces that break particles into smaller sizes and facilitate emulsification. Microfluidization involves forcing a liquid sample through microchannels at extremely high pressure, creating high shear rates and impact forces that result in uniform particle size reduction and stable emulsions. Both methods serve as advanced techniques for homogenization and particle size control in industries like pharmaceuticals, food processing, and nanotechnology.

Core Principles and Mechanisms

Ultrasonication utilizes high-frequency sound waves to generate cavitation bubbles that collapse and produce intense shear forces, promoting particle size reduction and homogenization in liquids. Microfluidization employs high-pressure jets forcing fluids through microchannels, causing collisions and shear forces at the microscopic level, resulting in uniform particle dispersion and enhanced mixing. Both techniques enhance emulsification and cell disruption but differ fundamentally in their energy delivery and fluid dynamics, impacting efficiency and scalability in processes like pharmaceutical formulation and nanomaterial synthesis.

Equipment and Operational Overview

Ultrasonication equipment utilizes high-frequency sound waves delivered through a probe or bath to create cavitation, effectively disrupting particles and promoting emulsification with adjustable amplitude and pulse settings. Microfluidization employs high-pressure pumps forcing fluids through microchannels or interaction chambers, generating shear and impact forces for fine particle size reduction and homogenization, with precise control over pressure and flow rate. Operationally, ultrasonication is suited for batch processes with limited volumes, while microfluidization supports continuous processing and scalability in industrial applications.

Particle Size Reduction Efficiency

Ultrasonication uses high-frequency sound waves to create cavitation bubbles that collapse and break particles into smaller sizes, achieving particle size reduction typically in the range of 100-500 nm depending on the material and process parameters. Microfluidization forces the sample through microchannels at high pressure, generating intense shear and impact forces that consistently reduce particle sizes to sub-100 nm levels with narrow size distribution. Studies demonstrate that microfluidization often achieves superior particle size reduction efficiency compared to ultrasonication, especially for producing stable nanoemulsions and uniform nanoparticles in pharmaceutical and food applications.

Applications in Pharmaceuticals and Food Industry

Ultrasonication enhances drug formulation by improving particle size reduction, emulsification, and bioavailability, making it ideal for pharmaceutical suspensions and nanoemulsions. Microfluidization achieves high-pressure homogenization, producing uniform liposomes and nanoparticles used in targeted drug delivery and vaccine development. In the food industry, ultrasonication aids in extraction, preservation, and texture modification, while microfluidization optimizes emulsions, stabilizes dairy products, and improves flavor encapsulation.

Energy Consumption and Process Scalability

Ultrasonication typically consumes less energy per unit volume in small-scale applications but faces significant efficiency losses when scaled up due to energy dissipation and equipment limitations. Microfluidization offers superior process scalability with consistent high shear forces and uniform particle size reduction, albeit at the cost of higher energy consumption and more complex operational requirements. Industrial applications favor microfluidization for large-scale homogenization, while ultrasonication remains preferred for energy-efficient laboratory and pilot-scale processes.

Product Quality and Homogeneity

Ultrasonication utilizes high-frequency sound waves to create cavitation, resulting in effective particle size reduction and improved emulsion stability, enhancing product quality by promoting uniform texture and enhanced bioavailability. Microfluidization applies high-pressure shear forces through microchannels, achieving superior homogeneity and consistent particle size distribution critical for pharmaceutical and food-grade emulsions. Both techniques improve product uniformity, but microfluidization offers finer control over particle size distribution, making it optimal for applications requiring stringent quality standards.

Maintenance and Operational Costs

Ultrasonication systems typically require lower initial investment and less complex maintenance due to simpler mechanical components, resulting in reduced operational costs for routine tasks. Microfluidization involves higher operational expenses driven by the need for specialized pumps, precision valves, and frequent part replacements to maintain consistent high pressures. Regular maintenance schedules and potential downtime for microfluidizers contribute to increased long-term costs compared to the relatively straightforward upkeep of ultrasonication equipment.

Advantages and Limitations of Each Technique

Ultrasonication offers precise control over particle size reduction and efficient cell disruption, making it ideal for lab-scale nanoparticle synthesis and emulsification, but its limited scalability and potential for heat generation pose challenges. Microfluidization provides high-throughput processing with consistent particle size distribution and superior mixing, favoring industrial applications in pharmaceuticals and food industries, though it requires higher initial investment and complex maintenance. Each technique's suitability depends on the specific processing volume, desired particle characteristics, and operational costs.

Conclusion: Choosing the Right Technology

Ultrasonication provides efficient cell disruption and emulsification through high-frequency sound waves, ideal for small-scale applications with moderate viscosity fluids. Microfluidization utilizes high-pressure homogenization to achieve uniform particle size reduction and improved product consistency, making it suitable for large-scale industrial processes requiring precise control. Selecting the right technology depends on factors such as processing scale, fluid characteristics, desired particle size, and production throughput requirements.

Ultrasonication Infographic

libterm.com

libterm.com