Opposed-piston engines achieve higher efficiency by eliminating cylinder heads and using two pistons moving in opposite directions within a single cylinder, reducing heat loss and improving combustion. This design offers compactness and lowers weight, making it ideal for applications in aerospace, military, and heavy-duty vehicles. Discover how opposed-piston technology can enhance Your engine's performance by reading the full article.

Table of Comparison

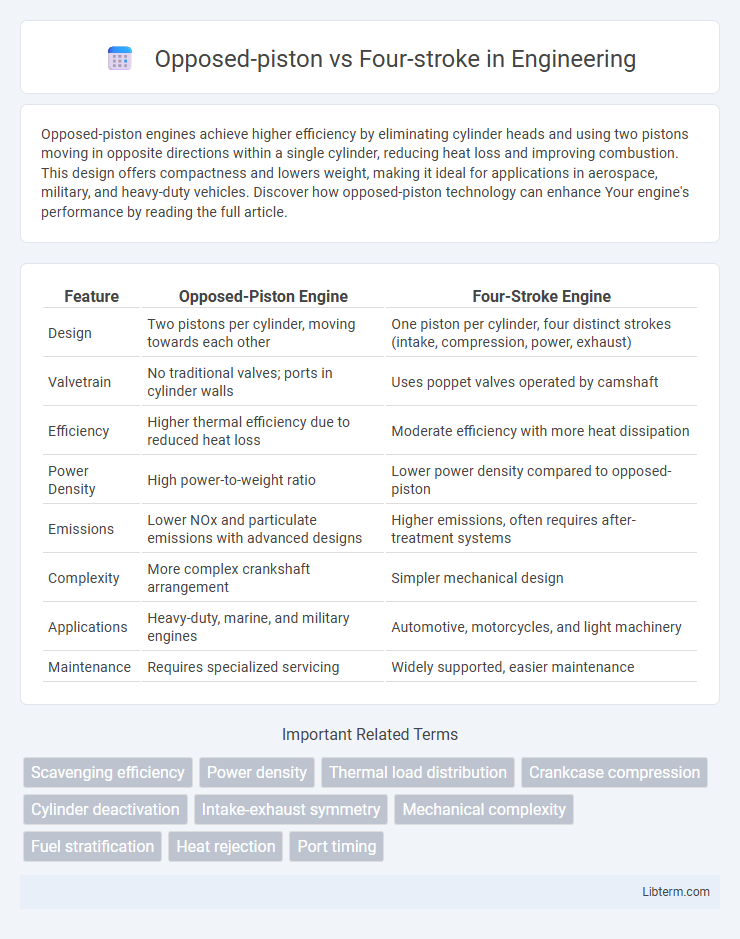

| Feature | Opposed-Piston Engine | Four-Stroke Engine |

|---|---|---|

| Design | Two pistons per cylinder, moving towards each other | One piston per cylinder, four distinct strokes (intake, compression, power, exhaust) |

| Valvetrain | No traditional valves; ports in cylinder walls | Uses poppet valves operated by camshaft |

| Efficiency | Higher thermal efficiency due to reduced heat loss | Moderate efficiency with more heat dissipation |

| Power Density | High power-to-weight ratio | Lower power density compared to opposed-piston |

| Emissions | Lower NOx and particulate emissions with advanced designs | Higher emissions, often requires after-treatment systems |

| Complexity | More complex crankshaft arrangement | Simpler mechanical design |

| Applications | Heavy-duty, marine, and military engines | Automotive, motorcycles, and light machinery |

| Maintenance | Requires specialized servicing | Widely supported, easier maintenance |

Introduction to Opposed-Piston and Four-Stroke Engines

Opposed-piston engines feature two pistons per cylinder moving in opposite directions, eliminating the need for cylinder heads, which improves thermal efficiency and reduces weight. Four-stroke engines operate with a single piston per cylinder, completing intake, compression, power, and exhaust strokes in four distinct phases, offering simpler mechanics but potentially higher heat losses. The opposed-piston design enhances combustion efficiency and power density, while four-stroke engines provide reliable performance with established technology and widespread use.

Historical Evolution of Engine Designs

Opposed-piston engines emerged in the early 20th century as a compact, efficient alternative to traditional four-stroke engines, offering improved thermal efficiency by eliminating the cylinder head. Four-stroke engines, patented by Nikolaus Otto in 1876, became dominant due to their simpler valve mechanism and easier maintenance, fueling widespread adoption in automotive and industrial applications. Over time, advances in materials and fuel injection have renewed interest in opposed-piston designs for their potential fuel economy and emissions benefits, reflecting a cyclical evolution in engine technology driven by efficiency and environmental demands.

Core Operating Principles

Opposed-piston engines operate by having two pistons within a single cylinder moving toward and away from each other to compress and power the combustion process, eliminating the need for cylinder heads and valves. Four-stroke engines function through a sequential intake, compression, power, and exhaust stroke using a single piston per cylinder aided by a valvetrain system. The opposed-piston design achieves combustion using opposing pistons acting as both intake and exhaust valves, while four-stroke engines rely on cam-driven valves for gas exchange.

Comparative Efficiency and Power Output

Opposed-piston engines often achieve higher thermal efficiency due to reduced heat losses and improved combustion chamber design compared to traditional four-stroke engines. The absence of a cylinder head in opposed-piston designs minimizes surface area, enhancing power density and fuel utilization. Four-stroke engines typically offer lower specific power output but benefit from simpler valve mechanisms and consistent lubrication systems, which can impact overall efficiency differently.

Fuel Consumption and Emissions

Opposed-piston engines typically achieve better fuel consumption due to reduced heat loss and fewer moving parts, enhancing thermal efficiency compared to traditional four-stroke engines. Emissions from opposed-piston designs are generally lower, benefiting from improved combustion control and lower internal friction, which reduces unburned fuel and nitrogen oxide (NOx) emissions. Four-stroke engines, while established and widely used, often have higher fuel consumption and emissions due to valve operation losses and less compact combustion chambers.

Mechanical Complexity and Maintenance

Opposed-piston engines feature fewer moving parts, such as the absence of a traditional cylinder head and valve train, leading to reduced mechanical complexity compared to four-stroke engines, which have more components like camshafts and valves requiring regular adjustment. Maintenance is often simpler in opposed-piston designs due to fewer parts subject to wear and less frequent valve servicing, while four-stroke engines demand ongoing valve clearance checks, timing belt replacements, and more intricate troubleshooting. The streamlined architecture of opposed-piston engines can result in lower maintenance costs and improved reliability over time relative to conventional four-stroke powerplants.

Size, Weight, and Packaging Considerations

Opposed-piston engines offer a more compact size and reduced weight compared to traditional four-stroke engines due to the elimination of cylinder heads and separate valve trains. Their compact packaging allows for better space utilization in confined engine bays, making them ideal for applications requiring high power density. Four-stroke engines, however, tend to have larger overall dimensions and weight because of the complexity of camshafts, valves, and cylinder head components, impacting vehicle design and weight distribution.

Application Suitability Across Industries

Opposed-piston engines excel in heavy-duty applications such as marine propulsion, power generation, and military vehicles due to their high power density and fuel efficiency. Four-stroke engines dominate the automotive and small machinery sectors, offering smoother operation, lower emissions, and easier maintenance. Industrial sectors prioritize opposed-piston designs for their compactness and thermal efficiency, while four-stroke engines remain preferred for regulatory compliance and versatility in light-duty applications.

Technological Developments and Innovations

Opposed-piston engines feature innovative dual combustion chambers and absence of cylinder heads, enhancing thermal efficiency and reducing mechanical friction compared to traditional four-stroke designs. Advanced materials and precision manufacturing have enabled improved durability and performance in opposed-piston engines, while four-stroke engines continue to evolve with turbocharging and direct fuel injection for emissions reduction. Emerging technologies in opposed-piston configurations, such as integrated crankshaft designs and sophisticated electronic controls, are driving their resurgence in commercial and military applications, challenging the long-standing dominance of four-stroke engines.

Future Prospects and Industry Trends

Opposed-piston engines offer significant advantages in fuel efficiency and emissions reduction compared to traditional four-stroke engines, aligning with future automotive and heavy-duty transport industry goals. Emerging trends emphasize integrating advanced materials and hybrid systems to enhance the performance and durability of opposed-piston designs. Global regulatory pressure and the shift toward sustainable mobility drive increased research investment, positioning opposed-piston technology as a promising alternative in next-generation powertrains.

Opposed-piston Infographic

libterm.com

libterm.com