Corrective maintenance involves repairing or restoring equipment after a failure or malfunction to ensure it returns to proper working condition. This type of maintenance is essential for minimizing downtime and preventing extended disruptions in operations. Discover how corrective maintenance can improve your system's reliability and efficiency by reading the full article.

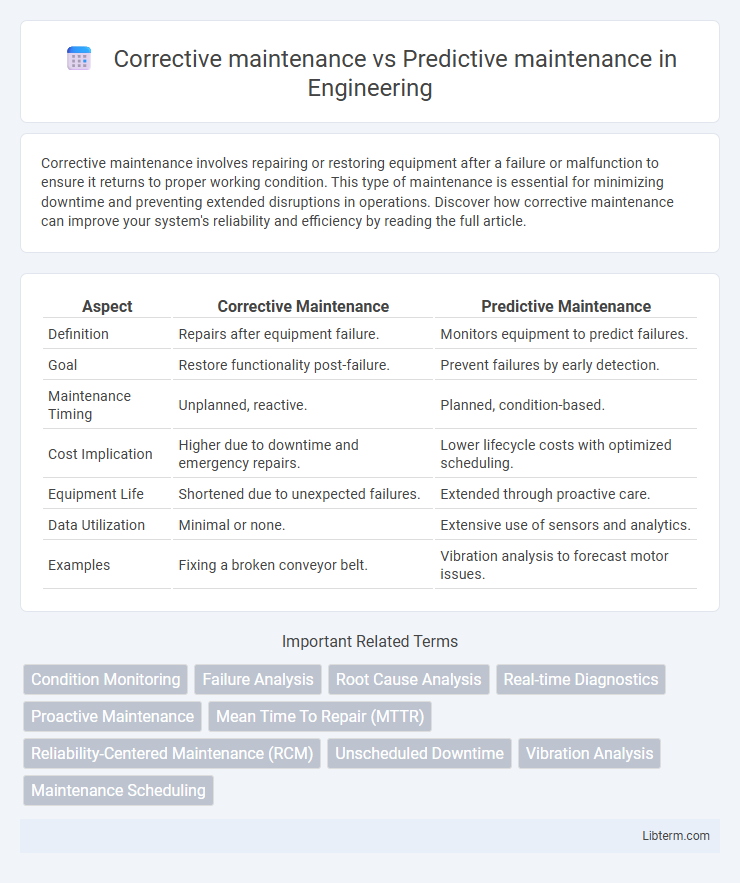

Table of Comparison

| Aspect | Corrective Maintenance | Predictive Maintenance |

|---|---|---|

| Definition | Repairs after equipment failure. | Monitors equipment to predict failures. |

| Goal | Restore functionality post-failure. | Prevent failures by early detection. |

| Maintenance Timing | Unplanned, reactive. | Planned, condition-based. |

| Cost Implication | Higher due to downtime and emergency repairs. | Lower lifecycle costs with optimized scheduling. |

| Equipment Life | Shortened due to unexpected failures. | Extended through proactive care. |

| Data Utilization | Minimal or none. | Extensive use of sensors and analytics. |

| Examples | Fixing a broken conveyor belt. | Vibration analysis to forecast motor issues. |

Understanding Corrective Maintenance

Corrective maintenance involves repairing equipment or systems after a failure has occurred, aiming to restore functionality promptly and minimize downtime. This approach prioritizes addressing unexpected breakdowns without prior condition monitoring, often leading to higher costs and unplanned interruptions. Understanding corrective maintenance is essential for managing emergencies and balancing repair expenses against the operational risks of postponing maintenance actions.

Defining Predictive Maintenance

Predictive maintenance relies on real-time data and advanced analytics to forecast equipment failures before they occur, reducing unplanned downtime and repair costs. Unlike corrective maintenance, which addresses issues only after breakdowns happen, predictive maintenance uses sensors and machine learning algorithms to optimize maintenance schedules and extend asset lifespan. Implementing predictive maintenance enhances operational efficiency by enabling proactive interventions based on condition monitoring and performance trends.

Key Differences Between Corrective and Predictive Maintenance

Corrective maintenance involves repairing equipment after a failure occurs, leading to unplanned downtime and higher costs, whereas predictive maintenance uses real-time data and analytics to forecast potential issues and schedule maintenance proactively. The key differences lie in timing and approach: corrective maintenance is reactive, addressing problems post-failure, while predictive maintenance is proactive, minimizing unexpected breakdowns through condition monitoring and predictive analytics. Predictive maintenance improves asset reliability and reduces maintenance expenses by preventing failures, contrasting with the often costly and disruptive nature of corrective interventions.

Advantages of Corrective Maintenance

Corrective maintenance offers the advantage of lower upfront costs by addressing equipment issues only after failures occur, reducing unnecessary inspections and interventions. It simplifies scheduling since repairs are performed as needed, which can be beneficial for non-critical machinery with low downtime impact. This approach maximizes the use of equipment lifespan before resources are allocated to maintenance activities.

Benefits of Predictive Maintenance

Predictive maintenance leverages real-time data and advanced analytics to forecast equipment failures, significantly reducing unexpected downtime and repair costs compared to corrective maintenance. By identifying potential issues before they escalate, predictive maintenance extends asset lifespan and optimizes maintenance schedules for improved operational efficiency. This proactive approach enhances productivity and decreases the total cost of ownership, delivering superior return on investment in industrial and manufacturing environments.

Common Challenges in Corrective Maintenance

Corrective maintenance often faces common challenges such as unexpected equipment downtime, higher repair costs, and inefficient resource allocation due to reactive management. Unlike predictive maintenance, which relies on data-driven insights to anticipate failures, corrective maintenance struggles with lack of real-time monitoring and limited failure pattern analysis. These obstacles lead to decreased operational efficiency and increased risk of prolonged production interruptions.

Risks and Limitations of Predictive Maintenance

Predictive maintenance relies heavily on accurate data collection and sophisticated algorithms, making it vulnerable to risks such as sensor failure, data inaccuracies, and false predictions that can lead to unexpected downtime. The limitations include high initial costs for sensor installation and data analytics infrastructure, as well as the need for skilled personnel to interpret complex data outputs effectively. Overreliance on predictive models may also result in missed early warning signs when anomalies do not conform to historical patterns, reducing the method's overall reliability.

Cost Comparison: Corrective vs Predictive Maintenance

Corrective maintenance typically incurs higher costs due to unexpected equipment failures leading to expensive emergency repairs and extended downtime. Predictive maintenance reduces overall expenses by using data-driven insights to perform timely interventions, minimizing unplanned outages and optimizing resource allocation. Over time, predictive maintenance proves more cost-effective by preventing major breakdowns and extending asset lifespan, despite requiring upfront investment in monitoring technologies.

When to Use Corrective or Predictive Maintenance

Corrective maintenance is ideal when equipment failure is unexpected, and immediate repair is necessary to restore functionality, typically in environments where downtime costs are low or spare parts are readily available. Predictive maintenance should be used when advanced diagnostics and sensor data can forecast potential failures, allowing for planned interventions that minimize unplanned downtime and extend asset life. Choosing between corrective and predictive maintenance depends on factors such as criticality of equipment, cost implications of downtime, and availability of condition monitoring technologies.

Future Trends in Industrial Maintenance Strategies

Future trends in industrial maintenance strategies emphasize the integration of predictive maintenance over corrective maintenance due to advancements in IoT sensors, machine learning algorithms, and real-time data analytics. Predictive maintenance enables early fault detection and optimized asset management, reducing unplanned downtime and maintenance costs compared to traditional corrective approaches. The growing adoption of digital twins and AI-driven diagnostics further accelerates the shift toward proactive maintenance, enhancing equipment reliability and operational efficiency.

Corrective maintenance Infographic

libterm.com

libterm.com