Compressive load refers to the force applied to materials or structures that causes them to be compacted or shortened. Understanding how your materials respond to compressive stress is crucial for ensuring structural integrity and preventing failure. Explore the rest of the article to learn how to effectively manage and design for compressive loads.

Table of Comparison

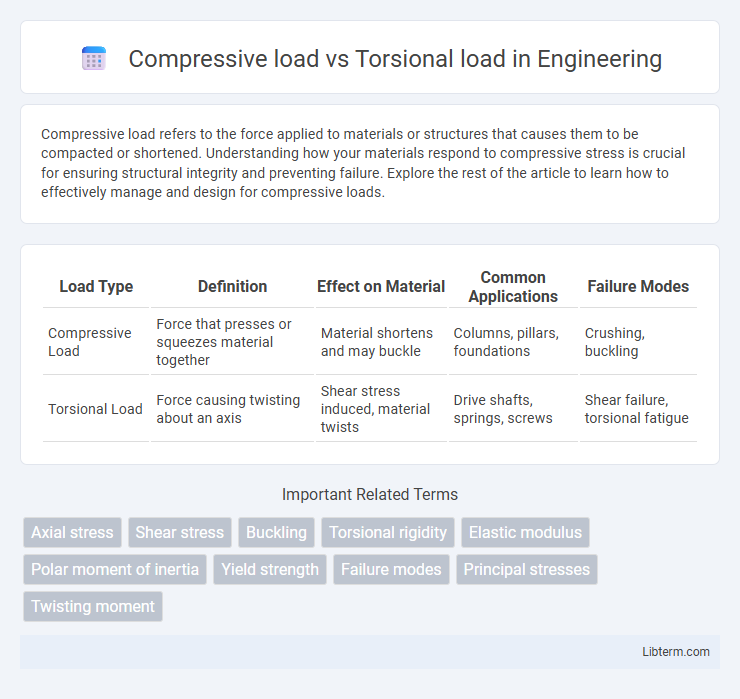

| Load Type | Definition | Effect on Material | Common Applications | Failure Modes |

|---|---|---|---|---|

| Compressive Load | Force that presses or squeezes material together | Material shortens and may buckle | Columns, pillars, foundations | Crushing, buckling |

| Torsional Load | Force causing twisting about an axis | Shear stress induced, material twists | Drive shafts, springs, screws | Shear failure, torsional fatigue |

Introduction to Compressive and Torsional Loads

Compressive load refers to a force that presses or squeezes a material, reducing its length and potentially causing deformation or failure through buckling or crushing. Torsional load involves twisting forces that create shear stress within a material, often leading to angular deformation or shear failure. Understanding these fundamental load types is essential for designing structures and mechanical components that can withstand specific stress conditions.

Defining Compressive Load

Compressive load refers to a force that acts to shorten or squeeze a material by applying pressure along its length, causing it to compact. It contrasts with torsional load, which involves twisting a material around its axis due to applied torque. Understanding compressive load is essential for analyzing structural stability and material strength under axial pressure conditions.

Understanding Torsional Load

Torsional load refers to the twisting force applied to an object, causing shear stress over its cross-section, which differs fundamentally from compressive load that pushes or squeezes material along its axis. Understanding torsional load involves analyzing torque and angular displacement, critical in designing shafts, beams, and structural components to prevent failure due to torsional shear stress. Accurate assessment of torsional load behavior ensures mechanical stability and longevity in applications ranging from automotive drivetrains to aerospace engineering.

Key Differences Between Compressive and Torsional Loads

Compressive loads apply force along the length of a material, causing it to shorten and potentially buckle, while torsional loads induce twisting by applying torque around the material's longitudinal axis. Compressive stresses are primarily axial and result in uniform stress distribution, whereas torsional stresses generate shear stress concentrated around the surface of the material. The key distinction lies in the nature of deformation: compressive loads lead to shortening or crushing, whereas torsional loads cause angular rotation and shear strain.

Material Response Under Compressive Load

Materials under compressive load experience deformation characterized by a reduction in length and potential bulging perpendicular to the load direction, with behavior dependent on material ductility and stiffness. The response includes elastic deformation followed by plastic deformation when the yield strength is exceeded, often leading to buckling in slender structures. Compressive strength and modulus of elasticity are critical parameters determining a material's ability to withstand compressive stresses without permanent damage or failure.

Material Behavior Under Torsional Load

Materials under torsional load exhibit shear stress distribution, causing deformation primarily due to twisting motion along the longitudinal axis. Unlike compressive load, which results in axial shortening, torsional stress induces shear strain leading to potential shear failure or yielding depending on material ductility and shear modulus. Understanding the torsional load behavior is critical for designing shafts, beams, and other components subjected to torque to prevent fatigue and structural failure.

Applications of Compressive Load in Engineering

Compressive loads are extensively applied in structural engineering for designing columns, beams, and foundations that support heavy weights by resisting crushing forces, ensuring stability and safety. In civil engineering, compressive loads are critical in constructing bridges, dams, and high-rise buildings where materials like concrete and steel must withstand significant axial forces. Mechanical components such as hydraulic presses and load-bearing supports also utilize compressive loads to perform essential functions under controlled pressure conditions.

Common Uses of Torsional Load in Structures

Torsional loads play a crucial role in the design of structural elements such as bridges, shafts, and beams, where twisting forces impact overall stability. Common applications include drive shafts in vehicles, rotor blades in wind turbines, and certain building components subjected to lateral forces from wind or seismic activity. Understanding torsional load behavior ensures enhanced durability and safety in these critical engineering structures.

Failure Modes: Compression vs Torsion

Compressive loads primarily cause failure modes such as buckling, crushing, and material yielding due to axial forces acting along the length of a component, leading to deformation or collapse. Torsional loads result in shear stresses that induce failure modes like twisting, shear cracking, and fatigue fractures, particularly where torque causes rotational deformation. Understanding the distinct stress distributions and failure mechanisms under compression and torsion is critical for designing materials and structures to prevent catastrophic failure.

Choosing the Right Load Type for Structural Design

Selecting between compressive and torsional loads in structural design depends on the nature of forces expected in application and material behavior under stress. Compressive loads primarily affect structural elements like columns and beams by pushing materials together, requiring high compressive strength to prevent buckling or crushing. Torsional loads introduce twisting forces, demanding materials with superior shear strength and rigidity, crucial in components such as shafts and drive systems where torque transmission is critical for performance and safety.

Compressive load Infographic

libterm.com

libterm.com