Resistance butt welding provides a strong, efficient joint by applying pressure and passing electric current through the materials to be welded, generating heat from electrical resistance. This method is ideal for joining cylindrical parts and offers excellent mechanical properties with minimal surface preparation. Discover how resistance butt welding can enhance your fabrication process in the following article.

Table of Comparison

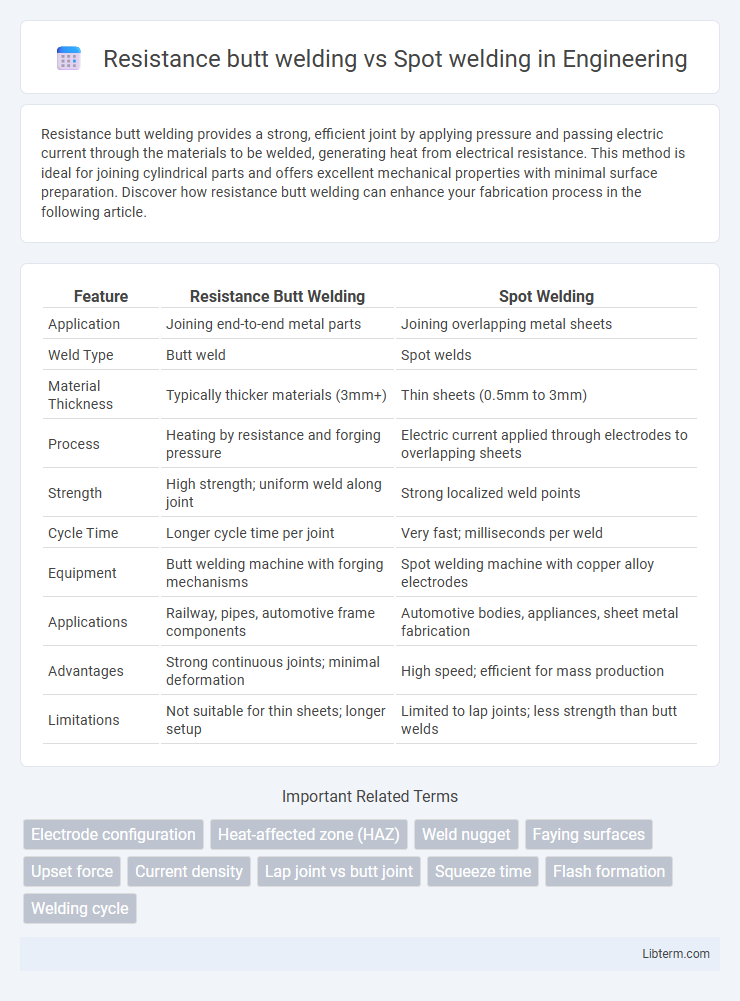

| Feature | Resistance Butt Welding | Spot Welding |

|---|---|---|

| Application | Joining end-to-end metal parts | Joining overlapping metal sheets |

| Weld Type | Butt weld | Spot welds |

| Material Thickness | Typically thicker materials (3mm+) | Thin sheets (0.5mm to 3mm) |

| Process | Heating by resistance and forging pressure | Electric current applied through electrodes to overlapping sheets |

| Strength | High strength; uniform weld along joint | Strong localized weld points |

| Cycle Time | Longer cycle time per joint | Very fast; milliseconds per weld |

| Equipment | Butt welding machine with forging mechanisms | Spot welding machine with copper alloy electrodes |

| Applications | Railway, pipes, automotive frame components | Automotive bodies, appliances, sheet metal fabrication |

| Advantages | Strong continuous joints; minimal deformation | High speed; efficient for mass production |

| Limitations | Not suitable for thin sheets; longer setup | Limited to lap joints; less strength than butt welds |

Introduction to Resistance Butt Welding and Spot Welding

Resistance butt welding joins two metal pieces end-to-end by applying heat generated from electrical resistance and pressure, creating a strong, continuous bond ideal for pipes and rods. Spot welding fuses overlapping metal sheets at discrete points through localized heat and pressure, commonly used in automotive and sheet metal industries for its speed and precision. Both techniques rely on electrical resistance but serve different applications, with butt welding favoring linear joints and spot welding emphasizing point connections.

Core Principles of Resistance Butt Welding

Resistance butt welding uses the principle of applying electric current and pressure to the ends of two metal workpieces, generating localized heat through electrical resistance to form a strong, continuous joint. Unlike spot welding, which joins overlapping sheets at discrete points, butt welding aligns and fuses end-to-end, ensuring uniform strength along the joint line. The core parameters influencing resistance butt welding include current intensity, electrode pressure, and weld time, all critical for achieving optimal metallurgical bonding and minimizing defects.

Core Principles of Spot Welding

Spot welding relies on the core principle of applying pressure and passing a high electric current through metal surfaces at the welding point, causing localized melting and fusion. Resistance butt welding, in contrast, joins pieces end-to-end by heating their abutting surfaces through resistance and pressure without overlapping. Spot welding offers rapid, precise joints ideal for sheet metal fabrication, leveraging electrical resistance and electrode force to create strong, consistent welds.

Key Differences Between Butt Welding and Spot Welding

Resistance butt welding joins two metal pieces end-to-end by applying heat and pressure directly at the joint, creating a strong, continuous weld ideal for pipes and rods. Spot welding involves clamping two overlapping metal sheets and passing an electric current through small electrodes, producing localized weld spots suitable for thin sheet metals in automotive and manufacturing industries. Key differences include joint configuration, with butt welding forming linear seams and spot welding creating discrete weld points, as well as the thickness and types of materials each method best accommodates.

Equipment and Process Requirements

Resistance butt welding requires heavy-duty equipment including DC power sources, electrode holders, and precise clamping systems to align and press the workpieces together under high current for a continuous weld. In contrast, spot welding equipment involves a pair of copper electrodes that deliver localized pressure and high current for short durations to create discrete weld spots between overlapping metal sheets. The butt welding process demands more rigorous setup and control for proper heat distribution along the joint, whereas spot welding has faster cycle times with simpler equipment but is limited to sheet thickness and overlap configurations.

Material Suitability and Thickness Considerations

Resistance butt welding excels in joining thicker materials and thermoplastics due to its ability to provide full penetration welds with strong, consistent joints. Spot welding is more suitable for thinner sheet metals, particularly steel and aluminum, offering quick, localized welds ideal for delicate or thin-gauge materials. Material thickness in resistance butt welding typically ranges from 2 mm to over 20 mm, while spot welding is effective for thicknesses generally below 6 mm, influencing the choice based on joint strength and application requirements.

Strength and Durability Comparison

Resistance butt welding produces continuous joints with superior tensile strength and fatigue resistance compared to spot welding, which typically results in discrete weld points susceptible to stress concentration. The uniform heat distribution in butt welding ensures deeper fusion and minimal defects, enhancing overall joint durability in dynamic or high-load applications. Spot welding, while efficient for sheet metals, often exhibits lower strength and reduced longevity under cyclic loading due to smaller weld nugget sizes and potential for weld failure.

Typical Applications in Industry

Resistance butt welding is commonly used in pipeline fabrication, automotive frame assembly, and railcar manufacturing where continuous, strong joints are required for structural integrity. Spot welding is primarily applied in automotive body panels, appliance manufacturing, and electronic enclosures due to its efficiency in joining thin metal sheets at discrete points. Both processes are essential in industries demanding high-volume production with reliable metal joining techniques.

Advantages and Limitations of Each Method

Resistance butt welding offers strong, continuous joints suitable for thick or long workpieces, providing high tensile strength and minimal distortion. However, it requires precise alignment and is less effective on thin or irregularly shaped materials. Spot welding excels in fast, repetitive joining of sheet metals with localized heat application, ideal for automotive and appliance manufacturing, but it produces limited weld size and is less suitable for thick materials or structural applications.

Choosing the Right Welding Technique for Your Needs

Resistance butt welding provides strong, continuous joints ideal for pipes and structural components requiring high integrity, while spot welding suits sheet metal fabrication with quick, efficient welds at discrete points. Assess material thickness, joint design, and load requirements to determine the optimal technique, as butt welding excels in thicker, cylindrical parts and spot welding in thin, flat materials. Choose resistance butt welding for seamless strength and spot welding for speed and cost-effectiveness in mass production.

Resistance butt welding Infographic

libterm.com

libterm.com