Plane strain describes a deformation condition where strain in one dimension is negligible, typically occurring in long structures like tunnels or dams. This concept is crucial for accurately analyzing stress and displacement in engineering and geotechnical applications. Explore the rest of the article to understand how plane strain influences design and safety considerations.

Table of Comparison

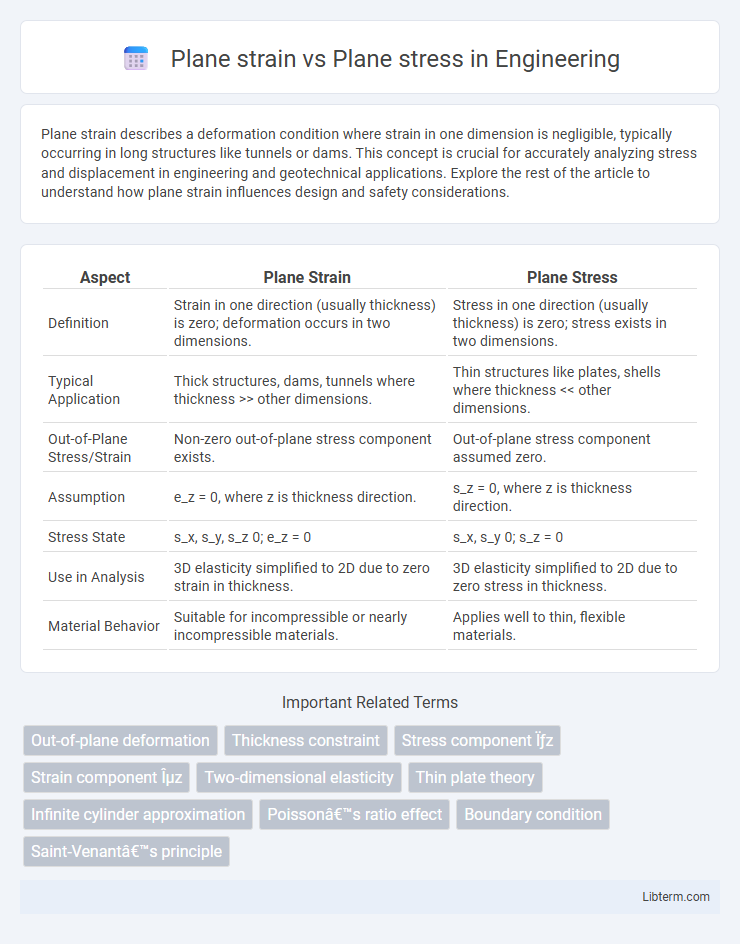

| Aspect | Plane Strain | Plane Stress |

|---|---|---|

| Definition | Strain in one direction (usually thickness) is zero; deformation occurs in two dimensions. | Stress in one direction (usually thickness) is zero; stress exists in two dimensions. |

| Typical Application | Thick structures, dams, tunnels where thickness >> other dimensions. | Thin structures like plates, shells where thickness << other dimensions. |

| Out-of-Plane Stress/Strain | Non-zero out-of-plane stress component exists. | Out-of-plane stress component assumed zero. |

| Assumption | e_z = 0, where z is thickness direction. | s_z = 0, where z is thickness direction. |

| Stress State | s_x, s_y, s_z 0; e_z = 0 | s_x, s_y 0; s_z = 0 |

| Use in Analysis | 3D elasticity simplified to 2D due to zero strain in thickness. | 3D elasticity simplified to 2D due to zero stress in thickness. |

| Material Behavior | Suitable for incompressible or nearly incompressible materials. | Applies well to thin, flexible materials. |

Introduction to Plane Strain and Plane Stress

Plane strain conditions occur in thick structures where deformation in the thickness direction is negligible, resulting in zero strain perpendicular to the plane. Plane stress conditions arise in thin structures or components where the stress through the thickness is assumed to be zero, allowing two-dimensional stress analysis. Understanding these fundamental assumptions enables engineers to simplify complex three-dimensional stress and strain problems into two-dimensional models for accurate mechanical behavior predictions.

Fundamental Concepts in Solid Mechanics

Plane strain refers to deformation where strain in one principal direction (usually the thickness) is zero, commonly applied to long structures with constant cross-sections, while plane stress assumes negligible stress normal to the surface, typical in thin plates subjected to in-plane loading. In solid mechanics, plane strain conditions simplify three-dimensional stress fields by reducing them to two-dimensional analysis with zero strain along the thickness, whereas plane stress simplifies by assuming zero out-of-plane stresses, affecting the formulation of stress-strain relationships and boundary conditions. Understanding the fundamental distinctions between plane strain and plane stress is crucial for accurate modeling of stress distributions and predicting material behavior under different loading and geometric constraints.

Definitions: Plane Strain vs. Plane Stress

Plane strain refers to a deformation state where strain in the thickness direction is assumed zero, typically applied to long structures with uniform cross-section under load. Plane stress describes a condition where stress perpendicular to the thin body's surface is negligible, common in thin plates subjected to in-plane loading. Understanding the distinction is crucial for accurate structural analysis and design in fields such as civil, mechanical, and aerospace engineering.

Key Assumptions and Validity Conditions

Plane strain assumes zero strain in the thickness direction, valid for long bodies where deformation along thickness is constrained, such as tunnels or dams. Plane stress assumes zero stress in the thickness direction, applicable to thin plates subjected to in-plane loads where out-of-plane stresses are negligible. Key assumptions for plane strain include infinite length and constrained thickness deformation, while plane stress requires thin geometry and negligible out-of-plane loading, ensuring accurate stress-strain predictions under these conditions.

Mathematical Formulations and Equations

Plane strain assumes zero strain in the out-of-plane direction, leading to e_z = 0 and the stress components s_x, s_y, and t_xy governed by Hooke's law with e_z = 0 constraint, commonly expressed as s_z = n(s_x + s_y) / (1 - n) for isotropic materials. Plane stress assumes zero stress in the out-of-plane direction, meaning s_z = 0, reducing the constitutive equations to s_x = E/(1-n^2) (e_x + ne_y) and s_y = E/(1-n^2) (e_y + ne_x) with t_xy = Gg_xy, where E is Young's modulus, n is Poisson's ratio, and G is the shear modulus. The mathematical difference hinges on boundary conditions applied in elasticity theory, fundamentally altering the stiffness matrix and stress-strain relationships in finite element analyses for thin plates (plane stress) versus thick bodies (plane strain).

Real-World Examples and Applications

Plane strain conditions commonly occur in long tunnels, dams, and thick-walled pressure vessels where deformation along one axis is negligible, resulting in stress confined to two dimensions. Plane stress conditions are typical in thin structures like aircraft wings, car panels, and sheet metal components where out-of-plane stresses are minimal due to the small thickness. Understanding these distinctions is crucial for accurate design and analysis in civil, aerospace, and mechanical engineering fields to prevent structural failure and optimize material use.

Differences in Material Behavior

Plane strain conditions occur when deformation in one direction is constrained, resulting in no strain along that axis and typically representing thick structures under load, where out-of-plane stresses are significant. In contrast, plane stress applies to thin structures where out-of-plane stresses are negligible, leading to more uniform in-plane deformation and differing stress distributions. These differences impact material behavior by influencing stress intensity, failure modes, and deformation patterns, critical for accurate structural analysis and design.

Stress and Strain Distribution Analysis

Plane strain assumes no strain occurs in the thickness direction, resulting in stress and strain distributions confined to the two in-plane directions, often applied in thick structures where out-of-plane deformation is negligible. Plane stress occurs when the stress in the thickness direction is zero, commonly used in thin plates where out-of-plane stresses dissipate, affecting the strain distribution primarily within the plane. Stress and strain analysis under plane strain typically shows higher normal stresses due to constraint in the thickness, whereas plane stress results reveal lower out-of-plane stresses, impacting design considerations in mechanical and structural engineering.

Selection Criteria: When to Use Plane Strain or Plane Stress

Plane strain conditions apply primarily in thick structures where deformation is constrained in the thickness direction, making it ideal for analyzing deep beams, long tunnels, and thick plates under load. Plane stress is suitable for thin structures such as thin plates or shells where stresses perpendicular to the surface are negligible, typically used in thin sheet metal or membrane analysis. Choosing between plane strain and plane stress depends on the geometry thickness and loading conditions, with plane strain favored for bodies with large thickness relative to in-plane dimensions and plane stress for thin bodies where out-of-plane stresses are minimal.

Summary and Engineering Implications

Plane strain occurs when deformation in one principal axis is constrained, resulting in negligible strain along that direction, commonly found in thick structures like dams or tunnels. Plane stress assumes negligible stress perpendicular to the plane, typical in thin components such as plates or sheets under in-plane loads. Understanding these conditions is critical for accurate stress analysis and design in engineering applications, ensuring structural integrity and material efficiency.

Plane strain Infographic

libterm.com

libterm.com