Mechanical friction is the resistance encountered when two surfaces slide or attempt to slide across each other, significantly affecting the efficiency of machines and devices. Understanding how factors like surface roughness, material properties, and lubrication influence friction can help reduce wear and energy loss. Explore the full article to learn how managing mechanical friction can improve the performance and longevity of your equipment.

Table of Comparison

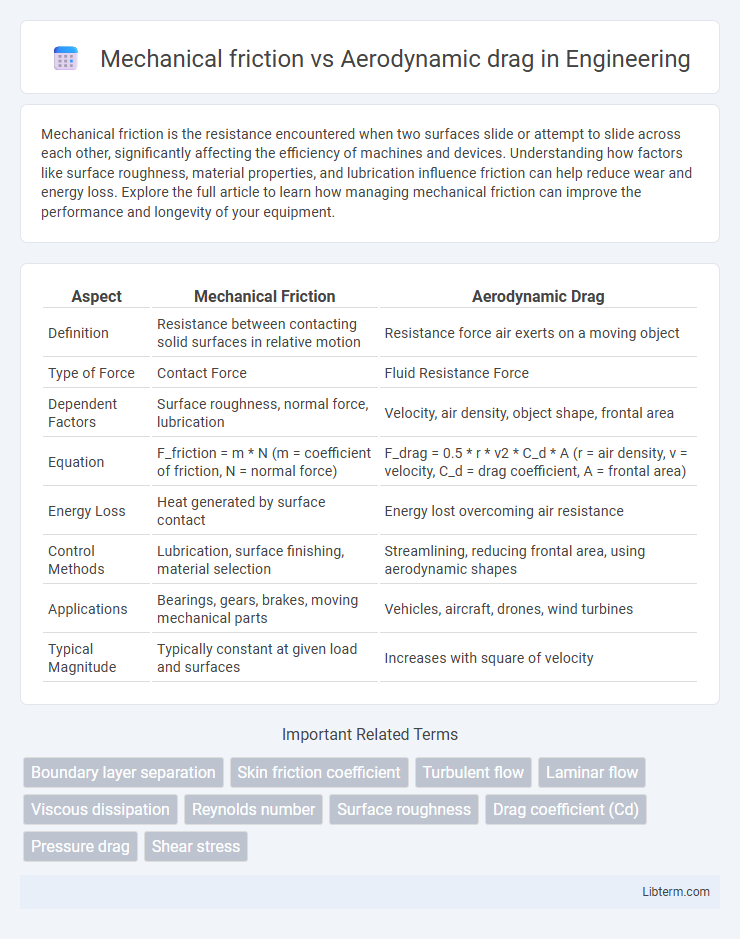

| Aspect | Mechanical Friction | Aerodynamic Drag |

|---|---|---|

| Definition | Resistance between contacting solid surfaces in relative motion | Resistance force air exerts on a moving object |

| Type of Force | Contact Force | Fluid Resistance Force |

| Dependent Factors | Surface roughness, normal force, lubrication | Velocity, air density, object shape, frontal area |

| Equation | F_friction = m * N (m = coefficient of friction, N = normal force) | F_drag = 0.5 * r * v2 * C_d * A (r = air density, v = velocity, C_d = drag coefficient, A = frontal area) |

| Energy Loss | Heat generated by surface contact | Energy lost overcoming air resistance |

| Control Methods | Lubrication, surface finishing, material selection | Streamlining, reducing frontal area, using aerodynamic shapes |

| Applications | Bearings, gears, brakes, moving mechanical parts | Vehicles, aircraft, drones, wind turbines |

| Typical Magnitude | Typically constant at given load and surfaces | Increases with square of velocity |

Introduction to Mechanical Friction and Aerodynamic Drag

Mechanical friction arises from the contact and relative motion between solid surfaces, causing resistance that converts kinetic energy into heat. Aerodynamic drag occurs when an object moves through a fluid such as air, generating a force opposite to the direction of motion due to pressure differences and viscous effects. Understanding the distinct mechanisms and factors influencing mechanical friction and aerodynamic drag is crucial for optimizing performance in engineering and transportation applications.

Definitions: Mechanical Friction vs. Aerodynamic Drag

Mechanical friction refers to the resistive force generated when two solid surfaces slide or rub against each other, resulting in energy loss primarily through heat. Aerodynamic drag is the force opposing an object's motion through a fluid, such as air, caused by pressure differences and viscous shear stresses acting on the object's surface. While mechanical friction depends on surface roughness and normal force, aerodynamic drag is governed by the object's shape, velocity, and fluid properties like density and viscosity.

Fundamental Principles Involved

Mechanical friction arises from the contact between solid surfaces where microscopic irregularities interlock, converting kinetic energy into heat through resistive forces. Aerodynamic drag results from the interaction between an object moving through a fluid medium, generating pressure and viscous forces that oppose motion. Both phenomena involve energy dissipation but differ fundamentally: mechanical friction depends on direct surface contact while aerodynamic drag is governed by fluid dynamics and flow behavior around the object.

Sources of Mechanical Friction in Machines

Mechanical friction in machines primarily originates from contact between moving parts such as bearings, gears, and sliding surfaces, where microscopic irregularities cause resistance. Surface roughness, material deformation, and lubrication quality significantly influence friction levels and energy loss in machinery. Unlike aerodynamic drag, which depends on air flow and object shape, mechanical friction is governed by direct physical interactions within machine components.

Origins of Aerodynamic Drag

Aerodynamic drag originates from the interaction between an object's surface and the surrounding air, characterized by pressure differences and viscous forces that resist motion. This phenomenon includes form drag, caused by shape and flow separation, and skin friction drag, resulting from air viscosity near the surface. Unlike mechanical friction, which arises from direct contact between solid surfaces, aerodynamic drag depends on fluid dynamics and air properties such as density and velocity.

Factors Affecting Mechanical Friction

Mechanical friction is influenced by surface roughness, material properties, and contact pressure between interacting surfaces, which determine the resistance force opposing motion. Lubrication, temperature, and wear also significantly impact the coefficient of friction by altering surface interactions and microstructures. Unlike aerodynamic drag, which depends on fluid flow characteristics and object shape, mechanical friction primarily relies on solid-to-solid contact parameters and material deformation.

Variables Influencing Aerodynamic Drag

Aerodynamic drag depends primarily on variables such as air density, velocity, frontal area, and drag coefficient, which is influenced by the shape and surface roughness of an object. Mechanical friction is affected by contact materials, normal force, and lubrication, but unlike aerodynamic drag, it does not vary significantly with speed. Understanding the dynamic nature of air flow and its interaction with objects is crucial for optimizing design to reduce drag and improve efficiency in vehicles and aircraft.

Impact on Energy Efficiency and Performance

Mechanical friction and aerodynamic drag significantly influence energy efficiency and performance in vehicles. Mechanical friction, arising from contact between moving parts such as bearings, gears, and tires, causes energy loss through heat, reducing mechanical efficiency and requiring more power to maintain motion. Aerodynamic drag, generated by air resistance acting against the vehicle's shape and speed, increases exponentially with velocity, demanding higher fuel consumption or energy output to overcome, thereby impacting acceleration, top speed, and overall fuel economy.

Strategies for Reducing Friction and Drag

Mechanical friction reduction strategies include using lubricants like oils and greases to minimize surface contact resistance and employing advanced materials such as low-friction coatings and polymers. Aerodynamic drag can be reduced by streamlining shapes to promote laminar airflow, incorporating aerodynamic add-ons like spoilers or vortex generators, and optimizing surface textures to decrease air turbulence. Combining these approaches enhances energy efficiency in vehicles and machinery by minimizing both mechanical friction and aerodynamic drag.

Real-World Applications and Comparisons

Mechanical friction primarily impacts applications involving contact between solid surfaces, such as bearings, brake systems, and conveyor belts, where energy loss and wear are critical concerns. Aerodynamic drag dominates in scenarios involving objects moving through air at high speeds, like aircraft, automobiles, and wind turbines, directly affecting fuel efficiency and performance. Comparing both, mechanical friction is typically constant and dependent on surface materials and lubrication, while aerodynamic drag varies with velocity and shape, necessitating distinct engineering approaches for optimization in real-world applications.

Mechanical friction Infographic

libterm.com

libterm.com