A higher pair in mechanical systems refers to contact interactions where surfaces touch along lines or curves rather than at fixed points, such as cam-follower or gear tooth engagements. This type of contact significantly influences friction, wear, and vibration in your machinery, making it crucial for optimizing performance and longevity. Explore the rest of the article to understand how higher pairs function and impact your mechanical designs.

Table of Comparison

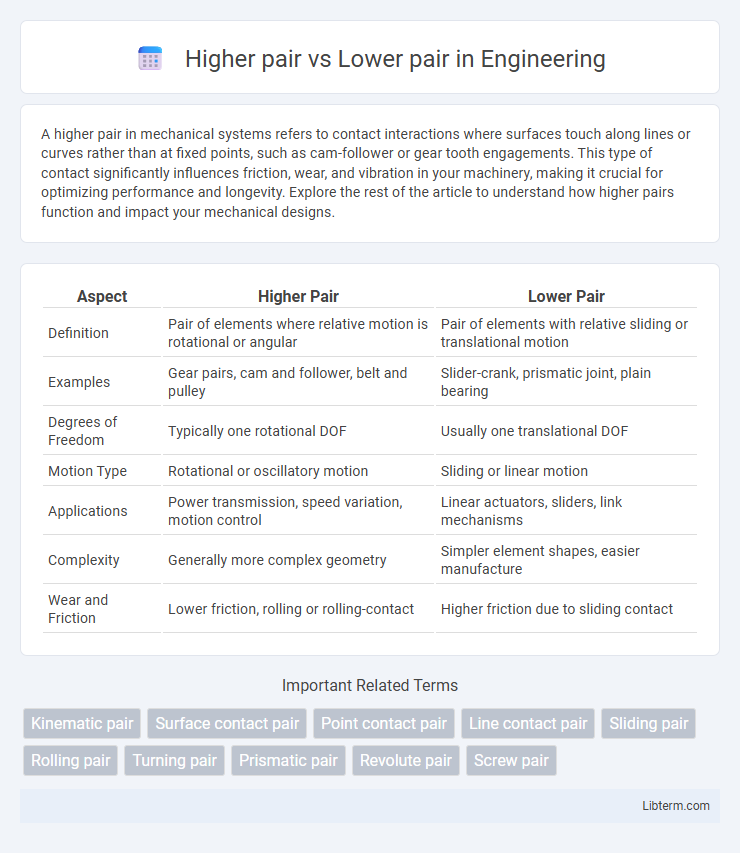

| Aspect | Higher Pair | Lower Pair |

|---|---|---|

| Definition | Pair of elements where relative motion is rotational or angular | Pair of elements with relative sliding or translational motion |

| Examples | Gear pairs, cam and follower, belt and pulley | Slider-crank, prismatic joint, plain bearing |

| Degrees of Freedom | Typically one rotational DOF | Usually one translational DOF |

| Motion Type | Rotational or oscillatory motion | Sliding or linear motion |

| Applications | Power transmission, speed variation, motion control | Linear actuators, sliders, link mechanisms |

| Complexity | Generally more complex geometry | Simpler element shapes, easier manufacture |

| Wear and Friction | Lower friction, rolling or rolling-contact | Higher friction due to sliding contact |

Introduction to Kinematic Pairs

Higher pairs involve contact between curved surfaces, allowing relative motion with changing contact points, such as cams or gears, which enable complex motion transfer. Lower pairs exhibit surface contact with fixed or constrained relative motion, typically involving revolute, prismatic, or cylindrical pairs common in mechanisms like hinges and sliders. Understanding kinematic pairs is essential for analyzing mechanical linkages and predicting system movement.

Defining Higher Pair and Lower Pair

A higher pair in poker consists of two cards that outrank an opponent's pair, such as a pair of Kings versus a pair of Tens. A lower pair is a pair of cards ranked below the opponent's pair, like a pair of Fours versus a pair of Eights. The comparison of higher and lower pairs determines the winner when no higher-ranked hands are formed.

Key Differences Between Higher and Lower Pairs

Higher pairs involve two elements connected by surface contact allowing relative sliding or rolling motion, typical in mechanisms like cams and gears, resulting in complex movement patterns. Lower pairs consist of elements connected through line or point contact enabling simpler rotational or translational motion, found in joints like hinges or sliders. The key difference lies in contact type--surface contact for higher pairs causing complex motion versus line/point contact in lower pairs providing constrained, predictable movements.

Types of Lower Pair Mechanisms

Lower pair mechanisms involve kinematic pairs with surface contact, typically categorized into types such as revolute (pin) pairs, which allow rotational motion around a fixed axis; prismatic (slider) pairs, enabling linear sliding movement; cam and follower pairs, converting rotary motion into reciprocating motion; and screw pairs that facilitate combined rotary and linear motion through helical threads. These pairs are fundamental in mechanical systems for creating constrained, precise motion paths compared to higher pairs, which have point or line contact and more complex motion profiles. Understanding the distinct types of lower pair mechanisms is crucial for designing efficient mechanical linkages and robotic joints.

Types of Higher Pair Mechanisms

Higher pair mechanisms involve contact between curved surfaces, leading to complex motions and varying velocities, unlike lower pairs which have surface or line contact. Types of higher pair mechanisms include rolling pair (such as cam-follower systems), spherical pair (ball joints), and point contact pairs found in gears or cams engaging with followers. These mechanisms are essential in converting motion types and optimizing mechanical efficiency in engineering designs.

Applications of Lower Pairs

Lower pairs provide crucial mechanical advantages in applications requiring rotational or sliding motion, such as in hinges, sliders, and cam mechanisms found in automotive engines and industrial machines. These pairs facilitate relative motion between connected components, enabling precise control and smooth operation in manufacturing robots, conveyor systems, and precision instruments. Their design minimizes friction and wear, enhancing durability and efficiency in repetitive motion tasks.

Applications of Higher Pairs

Higher pairs, such as cams and gears, play a crucial role in mechanical systems requiring complex motion control, including robotic arms and automotive transmissions. These pairs enable non-revolute motions and precise movement conversion, essential for applications like valve actuators and indexing mechanisms. Their ability to handle simultaneous rotary and translational motions makes them indispensable in precision engineering and automated machinery.

Advantages and Disadvantages of Lower Pairs

Lower pairs, such as revolute or prismatic joints, offer advantages like simpler construction, compact design, and precise motion control in mechanical linkages. They provide constrained, well-defined movement paths, enhancing stability and load-bearing capacity in applications like robotics and machinery. However, disadvantages include limited degrees of freedom and potential wear at contact surfaces due to sliding or rolling friction, which can reduce lifespan and increase maintenance needs.

Advantages and Disadvantages of Higher Pairs

Higher pairs, characterized by point or line contact between links, offer greater flexibility in mechanism design and allow for more complex motion patterns compared to lower pairs, which feature surface contact. The advantages of higher pairs include the ability to achieve higher degrees of freedom and accommodate non-circular, irregular surfaces in mechanical systems. However, disadvantages involve increased wear due to concentrated contact forces, higher friction, and often more precise manufacturing requirements to maintain performance and longevity.

Comparative Table: Higher Pair vs Lower Pair

The comparative table of Higher Pair vs Lower Pair highlights their key mechanical differences: Higher pairs involve point or line contact with relative motion typically involving rolling or sliding, while Lower pairs feature surface contact allowing for pure rolling motion with constraint degrees of freedom. Higher pairs exhibit more complex kinematics and higher wear rates due to concentrated stresses, whereas Lower pairs provide smoother motion and better load distribution. Common examples include cam-follower and gear tooth interfaces for Higher pairs, contrasted with pin joints and slider-crank mechanisms representing Lower pairs.

Higher pair Infographic

libterm.com

libterm.com