Flare is a powerful platform that enables seamless integration of smart contracts with multiple blockchains, enhancing interoperability and scalability. By leveraging Flare's innovative consensus mechanism, businesses can execute complex decentralized applications with increased efficiency and reduced costs. Discover how Flare can transform your blockchain experience by exploring the full details in the article ahead.

Table of Comparison

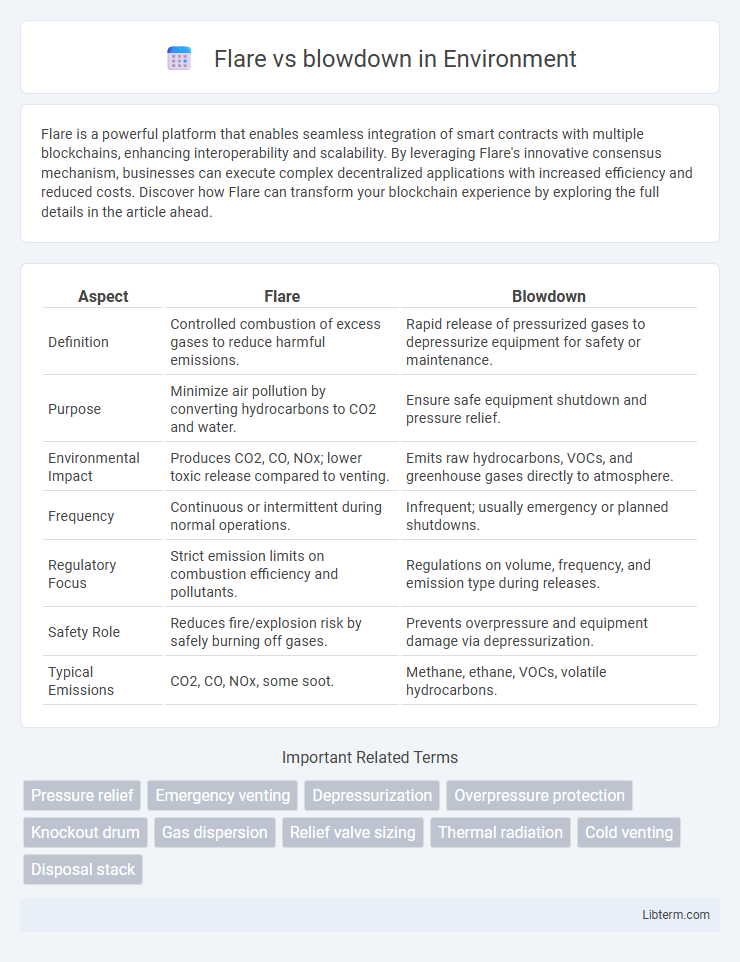

| Aspect | Flare | Blowdown |

|---|---|---|

| Definition | Controlled combustion of excess gases to reduce harmful emissions. | Rapid release of pressurized gases to depressurize equipment for safety or maintenance. |

| Purpose | Minimize air pollution by converting hydrocarbons to CO2 and water. | Ensure safe equipment shutdown and pressure relief. |

| Environmental Impact | Produces CO2, CO, NOx; lower toxic release compared to venting. | Emits raw hydrocarbons, VOCs, and greenhouse gases directly to atmosphere. |

| Frequency | Continuous or intermittent during normal operations. | Infrequent; usually emergency or planned shutdowns. |

| Regulatory Focus | Strict emission limits on combustion efficiency and pollutants. | Regulations on volume, frequency, and emission type during releases. |

| Safety Role | Reduces fire/explosion risk by safely burning off gases. | Prevents overpressure and equipment damage via depressurization. |

| Typical Emissions | CO2, CO, NOx, some soot. | Methane, ethane, VOCs, volatile hydrocarbons. |

Introduction to Flare and Blowdown Systems

Flare and blowdown systems are critical safety components in industrial plants designed to manage excess pressure and hazardous gases. Flare systems combust unwanted gases to reduce environmental impact and ensure safe disposal, while blowdown systems rapidly depressurize equipment to prevent overpressure incidents. Both systems play essential roles in maintaining plant safety and operational integrity by controlling pressure and minimizing risk during emergency conditions.

Key Differences Between Flare and Blowdown

Flare systems safely combust excess hydrocarbons by burning them at high temperatures, preventing hazardous gas release into the atmosphere, while blowdown systems rapidly depressurize equipment by venting gases to a safe location without combustion. Flares are designed to handle continuous or emergency gas releases with combustion efficiency limits, whereas blowdown valves provide quick pressure relief during emergency shutdowns without the need for gas burning. The main difference lies in flare's focus on gas destruction through combustion, compared to blowdown's role in immediate pressure reduction through controlled venting.

Purpose and Functionality of Flare Systems

Flare systems serve as critical safety devices in industrial plants to safely combust excess hydrocarbons and prevent hazardous overpressure during abnormal operations. Unlike blowdown systems that depressurize equipment by releasing gases to a safe location, flare systems convert these gases into less harmful emissions by burning them efficiently. This controlled combustion minimizes environmental impact and reduces fire and explosion risks associated with vented volatile compounds.

Purpose and Functionality of Blowdown Systems

Blowdown systems are designed to safely release excess pressure and remove hazardous gases or liquids from process equipment, preventing damage and ensuring operational safety. Unlike flare systems that combust gases, blowdown systems vent or discharge these substances directly, often to a safe containment or treatment area. Their primary function is to rapidly depressurize vessels and pipelines during emergency or maintenance conditions to mitigate risks of overpressure and potential explosions.

Operational Principles of Flare Technology

Flare technology operates by safely combusting waste gases released from industrial processes, using a controlled ignition system to convert hydrocarbons into less harmful emissions such as carbon dioxide and water vapor. The flare stack relies on a continuous pilot flame and appropriate gas flow control to maintain stable combustion and prevent unburned hydrocarbons from escaping into the atmosphere. Unlike blowdown systems that rapidly depressurize equipment to release gases, flares ensure environmental compliance by minimizing volatile organic compound (VOC) emissions and reducing flare tip noise through optimized burner design and proper gas velocity management.

Key Components of Blowdown Systems

Blowdown systems primarily consist of pressure relief valves, blowdown valves, and blowdown drums or tanks designed to safely discharge and contain gases or liquids released during pressure relief events. These components work together to reduce pressure within equipment, preventing overpressure and potential hazards by diverting excess fluids to controlled environments. Flare systems differ as they combust released gases to minimize environmental impact, whereas blowdown systems focus on pressure reduction and containment without combustion.

Safety Considerations: Flare vs Blowdown

Flare systems provide continuous combustion of hazardous gases, reducing the risk of explosive gas accumulation and toxic releases, which enhances facility safety. Blowdown systems rapidly depressurize equipment and release gases to a safe location but require careful design to prevent over-pressurization and minimize environmental impact. Effective safety management involves selecting the appropriate system based on operational scenarios, facility layout, and regulatory compliance to ensure maximum protection for personnel and the environment.

Environmental Impact: Flare vs Blowdown

Flare systems combust hydrocarbons, reducing volatile organic compound (VOC) emissions and lowering greenhouse gas impact, whereas blowdown releases unburned gases directly into the atmosphere, causing higher air pollution and potential toxic exposure. Flaring converts harmful methane and other hydrocarbons into less hazardous carbon dioxide and water vapor, mitigating climate change effects compared to blowdown's immediate release of raw gases. The environmental impact of blowdown is generally more severe, contributing to ozone formation, smog, and increased carbon footprint relative to controlled flaring processes.

Industry Applications and Use Cases

Flare systems are widely used in oil and gas industries for safely burning off excess hydrocarbons during process upsets, preventing pressure buildup and hazardous gas releases. Blowdown systems serve as critical safety measures in refineries and chemical plants, rapidly depressurizing vessels or pipelines to protect equipment and personnel during emergency shutdowns. Both systems are essential for compliance with environmental regulations and maintaining operational safety in high-pressure industrial processes.

Conclusion: Choosing the Right System

Selecting the appropriate system between flare and blowdown hinges on factors such as emission control efficiency, safety requirements, and operational costs. Flare systems provide effective combustion of hydrocarbons, minimizing environmental impact, while blowdown systems offer rapid depressurization but may release untreated gases. A thorough assessment of plant design, regulatory compliance, and process conditions ensures the optimal choice between flare and blowdown solutions.

Flare Infographic

libterm.com

libterm.com