Cable-stayed bridges feature towers connected directly to the bridge deck by cables, providing superior strength and efficient load distribution. This design allows for longer spans and greater stability compared to traditional bridge types, making it ideal for crossing wide bodies of water or challenging terrains. Discover how cable-stayed bridges could enhance Your infrastructure in the rest of this article.

Table of Comparison

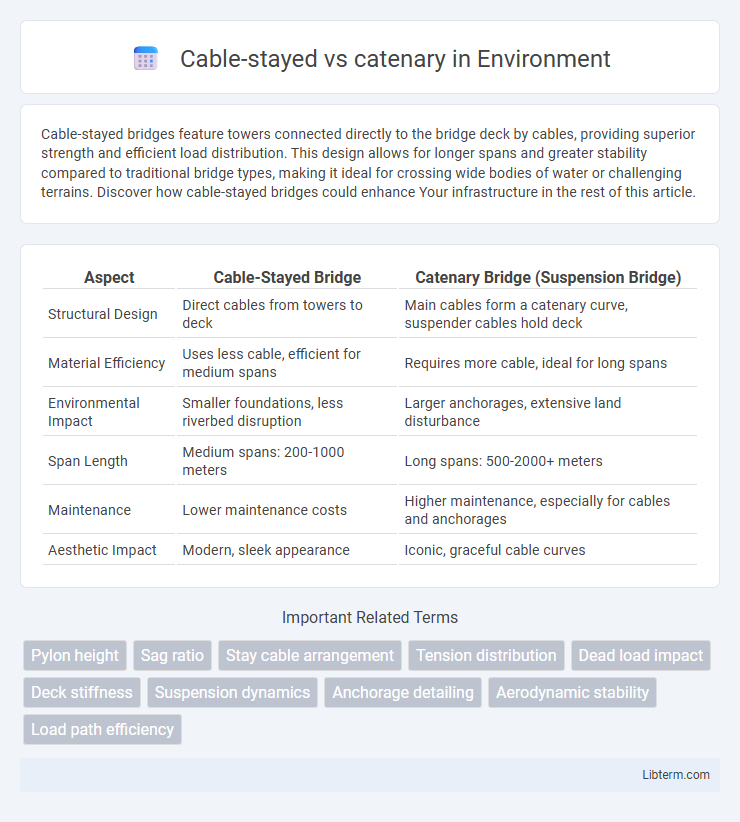

| Aspect | Cable-Stayed Bridge | Catenary Bridge (Suspension Bridge) |

|---|---|---|

| Structural Design | Direct cables from towers to deck | Main cables form a catenary curve, suspender cables hold deck |

| Material Efficiency | Uses less cable, efficient for medium spans | Requires more cable, ideal for long spans |

| Environmental Impact | Smaller foundations, less riverbed disruption | Larger anchorages, extensive land disturbance |

| Span Length | Medium spans: 200-1000 meters | Long spans: 500-2000+ meters |

| Maintenance | Lower maintenance costs | Higher maintenance, especially for cables and anchorages |

| Aesthetic Impact | Modern, sleek appearance | Iconic, graceful cable curves |

Introduction to Cable-Stayed and Catenary Systems

Cable-stayed systems use straight cables connected directly from towers to the deck, providing efficient load transfer and enhanced stiffness for medium to long spans. Catenary systems rely on flexible cables that form a natural curve under tension, ideal for supporting structures by evenly distributing loads over large distances. These fundamental differences influence material usage, structural behavior, and application suitability in bridge and architecture design.

Key Design Principles of Cable-Stayed Structures

Cable-stayed structures rely on tensioned cables directly connected to towers, efficiently transferring loads to the pylons and foundations, enhancing stability and reducing bending moments in the deck. The key design principles emphasize cable arrangement patterns such as fan, harp, or radial configurations to optimize load distribution and minimize material usage. This approach contrasts with catenary systems, where cables primarily support loads through their natural curve, experiencing mainly tensile forces without direct tower anchorage.

Core Concepts of Catenary Structures

Catenary structures are characterized by the natural curve formed by a flexible chain or cable suspended between two points under its own weight, creating an optimal shape for bearing uniform loads primarily through tension. Unlike cable-stayed bridges where cables are anchored directly to towers and support deck loads through inclined tension members, catenary systems rely on the intrinsic equilibrium of the hanging cable to distribute forces efficiently. Understanding the catenary curve is essential for designing lightweight, materially efficient structures such as suspension bridges and overhead power lines that maximize tensile capacity while minimizing bending moments.

Structural Differences: Cable-Stayed vs. Catenary

Cable-stayed bridges feature cables running directly from the towers to the deck, creating a series of straight tension members that efficiently transfer loads, while catenary bridges rely on cables hanging in a natural curve, distributing tension uniformly between anchors. The structural difference lies in the cable arrangement: cable-stayed systems use multiple inclined cables connected to pylons, resulting in a stiffer and lighter structure compared to the curved main cable in catenary systems, which typically supports suspension bridges. Cable-stayed bridges offer enhanced stiffness and reduced deck sag, whereas catenary cables enable longer spans with flexible load distribution.

Material Requirements and Construction Methods

Cable-stayed bridges utilize high-strength steel cables anchored directly to towers, requiring precise tensioning and prefabricated segments for rapid on-site assembly, allowing for efficient use of materials and reduced construction time. Catenary bridges rely on flexible cables forming a natural curve under tension, often requiring extensive anchorage systems and heavier materials to accommodate distributed loads, with construction demanding careful cable sag calculations and balance. Material optimization in cable-stayed designs emphasizes lightweight, high-tensile components, while catenary methods focus on durability and load distribution, impacting both the engineering approach and cost efficiency.

Load Distribution and Structural Efficiency

Cable-stayed bridges distribute load directly from the deck to the towers through straight cables, resulting in efficient transfer of tension forces and reduced bending moments, which enhances structural efficiency and allows for longer spans with fewer supports. Catenary bridges, such as suspension bridges, transfer loads via cables in a natural curved shape that primarily handle tension, while the deck experiences compression and bending, leading to a more complex load path and typically requiring massive anchorages to resist horizontal forces. The direct load path in cable-stayed designs improves stiffness and minimizes deck deformation, while the catenary system excels in spanning longer distances but with increased material and anchorage demands.

Architectural Applications and Aesthetic Impacts

Cable-stayed bridges feature cables directly connected from towers to the deck, allowing for slender, visually striking structures that emphasize verticality and modernity in architectural designs. In contrast, catenary systems, typical in suspension bridges, create elegant, sweeping curves that evoke a sense of fluidity and harmony with natural landscapes, often dominating skyline aesthetics with their expansive spans. The choice between cable-stayed and catenary designs significantly influences the bridge's visual impact and architectural integration, with cable-stayed structures offering sharper geometric lines and catenary forms providing graceful, organic silhouettes.

Cost Comparison and Economic Considerations

Cable-stayed bridges typically require less material and shorter construction time compared to catenary cable systems, leading to lower upfront costs and faster project completion. Catenary systems, often used in suspension bridges, incur higher expenses due to increased steel cable length and more complex anchoring structures. Long-term economic considerations favor cable-stayed designs for moderate spans due to reduced maintenance costs and enhanced durability under variable loads.

Durability, Maintenance, and Longevity

Cable-stayed bridges feature shorter cables with direct connections to towers, reducing cable fatigue and enhancing durability compared to the longer, curved cables of catenary designs. Maintenance of cable-stayed bridges is generally more straightforward due to easier cable inspections and replacements at accessible anchor points, while catenary cables require more complex monitoring. Longevity in cable-stayed bridges often surpasses catenary systems, as improved material stress distribution lowers deterioration rates and extends service life.

Choosing the Right System: Factors to Consider

Choosing the right bridge system depends on span length, load requirements, and environmental conditions. Cable-stayed bridges excel in medium to long spans with stiffness and design flexibility, while catenary systems, typical in suspension bridges, handle longer spans with efficient load distribution under tension. Cost, construction time, and aesthetic preferences also influence the decision between cable-stayed and catenary bridge systems.

Cable-stayed Infographic

libterm.com

libterm.com