Soil vapor extraction is an effective remediation technique that removes volatile contaminants from soil by applying vacuum to extract vapors through extraction wells. This method is widely used to treat polluted sites containing petroleum hydrocarbons, solvents, and other volatile organic compounds. Discover how this technology can help restore your contaminated soil by reading the rest of the article.

Table of Comparison

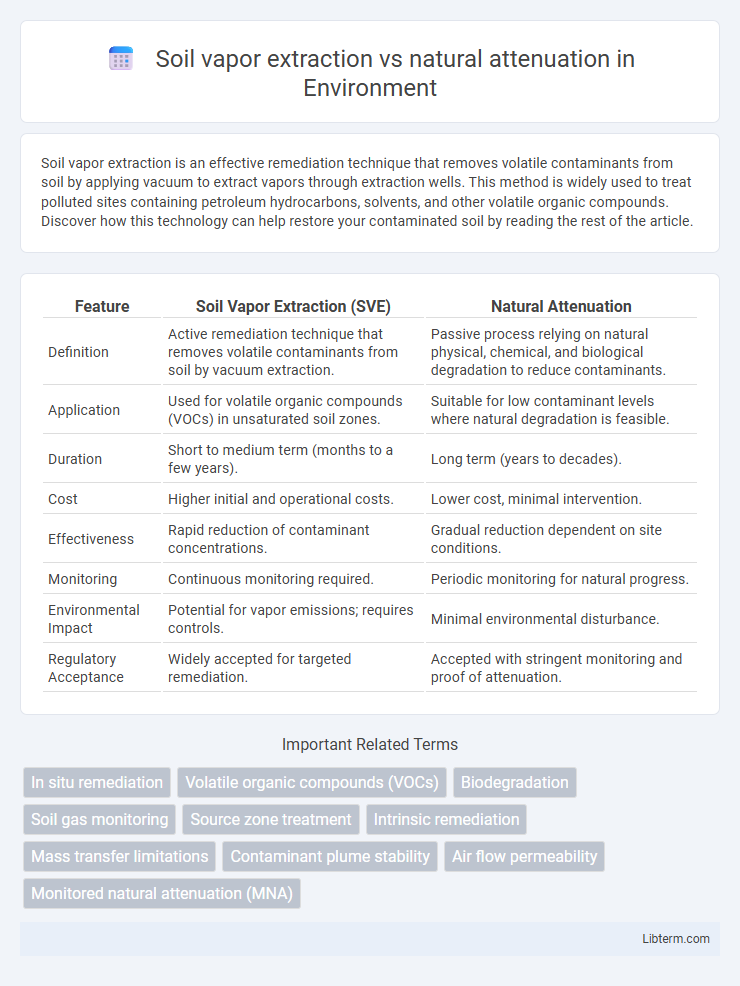

| Feature | Soil Vapor Extraction (SVE) | Natural Attenuation |

|---|---|---|

| Definition | Active remediation technique that removes volatile contaminants from soil by vacuum extraction. | Passive process relying on natural physical, chemical, and biological degradation to reduce contaminants. |

| Application | Used for volatile organic compounds (VOCs) in unsaturated soil zones. | Suitable for low contaminant levels where natural degradation is feasible. |

| Duration | Short to medium term (months to a few years). | Long term (years to decades). |

| Cost | Higher initial and operational costs. | Lower cost, minimal intervention. |

| Effectiveness | Rapid reduction of contaminant concentrations. | Gradual reduction dependent on site conditions. |

| Monitoring | Continuous monitoring required. | Periodic monitoring for natural progress. |

| Environmental Impact | Potential for vapor emissions; requires controls. | Minimal environmental disturbance. |

| Regulatory Acceptance | Widely accepted for targeted remediation. | Accepted with stringent monitoring and proof of attenuation. |

Introduction to Soil Vapor Extraction and Natural Attenuation

Soil vapor extraction (SVE) is an active remediation technology that removes volatile contaminants from the unsaturated soil zone by applying vacuum to extract vapors. Natural attenuation relies on inherent biological, chemical, and physical processes to degrade or immobilize contaminants without human intervention. SVE provides accelerated contaminant removal, whereas natural attenuation depends on site-specific conditions to achieve gradual cleanup over time.

Principles and Mechanisms of Soil Vapor Extraction

Soil vapor extraction (SVE) operates by applying a vacuum to subsurface soil to volatilize and remove volatile contaminants, primarily hydrocarbons and solvents, through extraction wells. This active remediation technique relies on principles of vapor pressure, soil permeability, and airflow dynamics to mobilize and capture contaminants in the vadose zone. In contrast, natural attenuation depends on in-situ biodegradation, chemical breakdown, and dispersion processes without mechanical intervention, making SVE a faster and more controlled method for removing volatile organic compounds from soil.

Understanding Natural Attenuation Processes

Natural attenuation relies on inherent biological, chemical, and physical processes to reduce contaminant concentrations in soil and groundwater without active intervention. Soil vapor extraction actively removes volatile contaminants by applying vacuum to the vadose zone, accelerating cleanup compared to the slower, passive mechanisms of natural attenuation. Understanding natural attenuation involves evaluating factors like microbial degradation, volatilization, adsorption, and chemical transformation to determine if it sufficiently mitigates contaminant risks over time.

Contaminants Addressed by Each Remediation Method

Soil vapor extraction effectively targets volatile organic compounds (VOCs) such as benzene, toluene, ethylbenzene, and xylene (BTEX) by extracting vapor-phase contaminants from the unsaturated zone. Natural attenuation primarily addresses contaminants like petroleum hydrocarbons, chlorinated solvents, and some metals through biodegradation, chemical reactions, and dilution processes in situ. The choice between these methods depends on contaminant volatility, biodegradability, and site-specific conditions impacting remediation efficiency.

Site Assessment and Applicability Criteria

Soil vapor extraction (SVE) requires thorough site assessment including soil permeability, contaminant volatility, and groundwater depth to ensure effective vapor removal from unsaturated zones. Natural attenuation relies on evaluating intrinsic bioremediation processes, such as microbial activity, oxygen levels, and contaminant concentration trends over time, to confirm contaminant degradation without active intervention. SVE is applicable in sites with volatile organic compounds (VOCs) and favorable soil conditions, while natural attenuation suits sites with low contaminant flux and stable geochemical conditions supporting degradation.

Comparative Effectiveness in Contaminant Removal

Soil vapor extraction (SVE) demonstrates higher efficiency in removing volatile organic compounds (VOCs) from the vadose zone by actively extracting contaminated vapors, achieving contaminant reductions often exceeding 70-90% in months. Natural attenuation relies on intrinsic biodegradation and physical dispersion processes, resulting in slower contaminant reduction rates that may take years to achieve comparable cleanup levels, particularly for recalcitrant compounds. Comparative studies indicate SVE outperforms natural attenuation in rapid contaminant mass removal, making it preferable for sites requiring accelerated remediation timelines.

Environmental Impact and Sustainability Considerations

Soil vapor extraction (SVE) actively removes volatile contaminants from the subsurface, reducing pollutant levels more rapidly but requiring energy consumption and equipment maintenance, which can impact carbon footprints. Natural attenuation relies on biological, chemical, and physical processes to degrade contaminants over time, minimizing energy use and disturbance but potentially prolonging exposure risks and site recovery. Balancing environmental impact and sustainability involves evaluating site-specific conditions, contaminant types, and long-term monitoring to ensure effective remediation with minimal ecological disruption.

Cost and Time Efficiency Analysis

Soil vapor extraction (SVE) offers faster contaminant removal, typically achieving remediation within months to a few years, while natural attenuation relies on longer timeframes, often spanning decades, making SVE more time-efficient despite higher upfront costs. Cost analysis shows SVE requires significant capital investment for equipment, operation, and monitoring, but can reduce long-term liability and accelerate site closure, whereas natural attenuation has lower immediate costs but may incur prolonged monitoring expenses. Evaluating both methods involves balancing the accelerated remediation and higher cost of SVE against the slower, lower-cost but uncertain outcomes of natural attenuation.

Regulatory Acceptance and Monitoring Requirements

Soil vapor extraction (SVE) is widely accepted by regulatory agencies such as the EPA due to its active remediation approach, which allows for faster contaminant removal and measurable progress through continuous monitoring of soil gas concentrations. Natural attenuation relies on intrinsic biogeochemical processes, often requiring comprehensive long-term monitoring, including groundwater sampling and contaminant plume analysis, to demonstrate contaminant reduction and regulatory compliance. Regulatory acceptance of natural attenuation is typically contingent on site-specific risk assessments and extensive evidence that natural processes will achieve cleanup goals within an acceptable timeframe.

Choosing the Right Remediation Strategy: Key Factors

Selecting the right remediation strategy between soil vapor extraction (SVE) and natural attenuation requires evaluating contamination type, site conditions, and timeframe goals. SVE is highly effective for volatile organic compounds in permeable soils, offering faster contaminant removal through active extraction. Natural attenuation suits less aggressive contamination scenarios, relying on natural processes but demanding thorough monitoring and longer remediation periods.

Soil vapor extraction Infographic

libterm.com

libterm.com