In-vessel composting accelerates organic waste decomposition by containing materials within a controlled environment, optimizing temperature, moisture, and aeration for efficient nutrient recycling. This method reduces odors, pests, and greenhouse gas emissions compared to traditional composting techniques, making it ideal for urban and industrial settings. Discover how in-vessel composting can transform your waste management strategy by reading the full article.

Table of Comparison

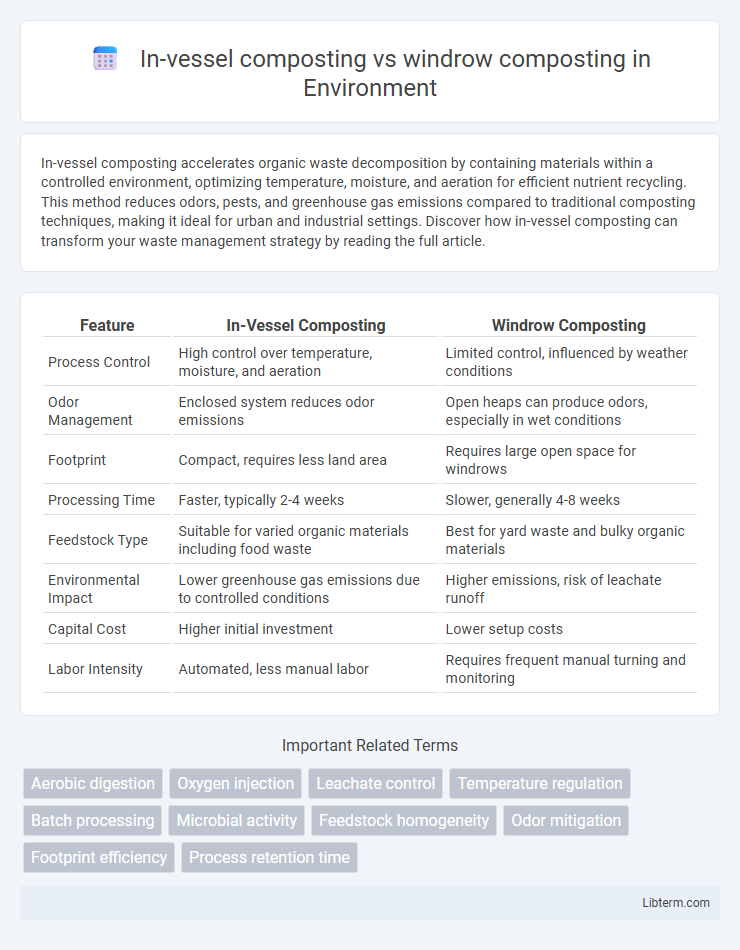

| Feature | In-Vessel Composting | Windrow Composting |

|---|---|---|

| Process Control | High control over temperature, moisture, and aeration | Limited control, influenced by weather conditions |

| Odor Management | Enclosed system reduces odor emissions | Open heaps can produce odors, especially in wet conditions |

| Footprint | Compact, requires less land area | Requires large open space for windrows |

| Processing Time | Faster, typically 2-4 weeks | Slower, generally 4-8 weeks |

| Feedstock Type | Suitable for varied organic materials including food waste | Best for yard waste and bulky organic materials |

| Environmental Impact | Lower greenhouse gas emissions due to controlled conditions | Higher emissions, risk of leachate runoff |

| Capital Cost | Higher initial investment | Lower setup costs |

| Labor Intensity | Automated, less manual labor | Requires frequent manual turning and monitoring |

Introduction to Composting Methods

In-vessel composting involves processing organic waste within a closed container, allowing for better control of temperature, moisture, and aeration, which accelerates decomposition and reduces odors. Windrow composting consists of layering organic materials in long, open piles turned periodically, suitable for large volumes of yard waste but dependent on weather conditions. Both methods aim to transform organic waste into nutrient-rich compost, with in-vessel offering higher efficiency and windrow providing cost-effective scalability.

Overview of In-vessel Composting

In-vessel composting involves the controlled aerobic decomposition of organic waste within a closed, insulated container, allowing for precise regulation of temperature, moisture, and oxygen levels. This method accelerates the composting process, reduces odor emissions, and minimizes the risk of pathogen survival compared to open-air windrow composting. In-vessel systems are ideal for managing diverse organic materials, including food waste and biosolids, in urban or space-constrained environments.

Overview of Windrow Composting

Windrow composting is an aerobic process that involves forming organic waste into long, narrow piles called windrows, which are regularly turned to maintain oxygen levels and promote microbial activity. This method is widely used for yard waste, agricultural residues, and organic municipal solid waste due to its cost-effectiveness and scalability. Temperature control and moisture management are crucial factors in windrow composting to optimize decomposition and reduce odors.

Process and Technology Comparison

In-vessel composting involves controlled, enclosed systems that regulate temperature, moisture, and aeration for rapid organic waste decomposition, using rotating drums or static vessels equipped with sensors. Windrow composting relies on open-air, elongated piles turned manually or mechanically to facilitate aerobic microbial activity, requiring larger space and longer processing time. The advanced technology in in-vessel composting enables faster stabilization and pathogen reduction, while windrow composting offers a cost-effective solution with lower infrastructure complexity.

Space and Infrastructure Requirements

In-vessel composting requires significantly less space than windrow composting, making it ideal for urban or constrained environments where land availability is limited. The enclosed systems used in in-vessel composting facilitate better control over temperature, moisture, and aeration, reducing infrastructure footprint while enhancing process efficiency. Conversely, windrow composting demands expansive land area with minimal structural investment, relying on open-air piles that require sufficient space for turning equipment and aeration maintenance.

Efficiency and Composting Speed

In-vessel composting offers higher efficiency and faster composting speed due to controlled temperature, moisture, and aeration within an enclosed system, enabling optimal microbial activity and reduced processing time. Windrow composting relies on natural aeration and weather conditions, resulting in slower decomposition rates and lower efficiency compared to in-vessel methods. The in-vessel process can reduce composting duration from several months to a few weeks, making it ideal for large-scale organic waste management.

Environmental Impact and Emissions

In-vessel composting significantly reduces environmental impact by containing organic waste within a closed system, minimizing odor, leachate, and greenhouse gas emissions such as methane and nitrous oxide. Windrow composting, although cost-effective for large volumes, exposes materials to open air, leading to higher emissions and the potential release of pollutants into surrounding soil and water. Studies indicate in-vessel systems offer better control over process parameters, resulting in more efficient carbon stabilization and lower overall emissions.

Cost Analysis and Budget Considerations

In-vessel composting typically involves higher initial capital investment due to the need for enclosed systems, advanced aeration controls, and automated equipment, making it suitable for urban or space-constrained sites with budgets exceeding $500,000. Windrow composting offers a lower-cost alternative as it primarily uses open-air piles and minimal infrastructure, often with startup expenses below $100,000, but requires larger land area and ongoing labor costs for turning and monitoring. Operational expenses for in-vessel systems include energy consumption and maintenance of mechanical parts, while windrow systems incur higher labor and potential odor management costs, influencing the overall budget depending on scale and site conditions.

Suitability for Different Waste Types

In-vessel composting is highly suitable for processing a wide range of organic waste types, including food scraps, manure, and biosolids, due to its controlled environment that accelerates decomposition and minimizes odors. Windrow composting is better suited for bulky, less odorous materials such as yard waste, agricultural residues, and some food processing byproducts, benefiting from natural aeration and lower operational costs. The choice between these methods depends on waste composition, desired processing speed, and environmental impact considerations.

Choosing the Right Composting Method

In-vessel composting offers precise temperature control and faster decomposition, making it ideal for managing food waste and biosolids in urban areas with space constraints. Windrow composting is more cost-effective and suitable for large-scale agricultural or yard waste operations with ample outdoor space, allowing natural aeration through turning. Selecting the right composting method depends on waste type, volume, available space, odor control needs, and budget considerations to optimize organic waste management effectively.

In-vessel composting Infographic

libterm.com

libterm.com