Expanding your business requires strategic planning, resource allocation, and market analysis to ensure sustainable growth. Focusing on enhancing product offerings and customer engagement can lead to increased brand visibility and revenue streams. Explore our comprehensive guide to discover effective expansion strategies tailored for your success.

Table of Comparison

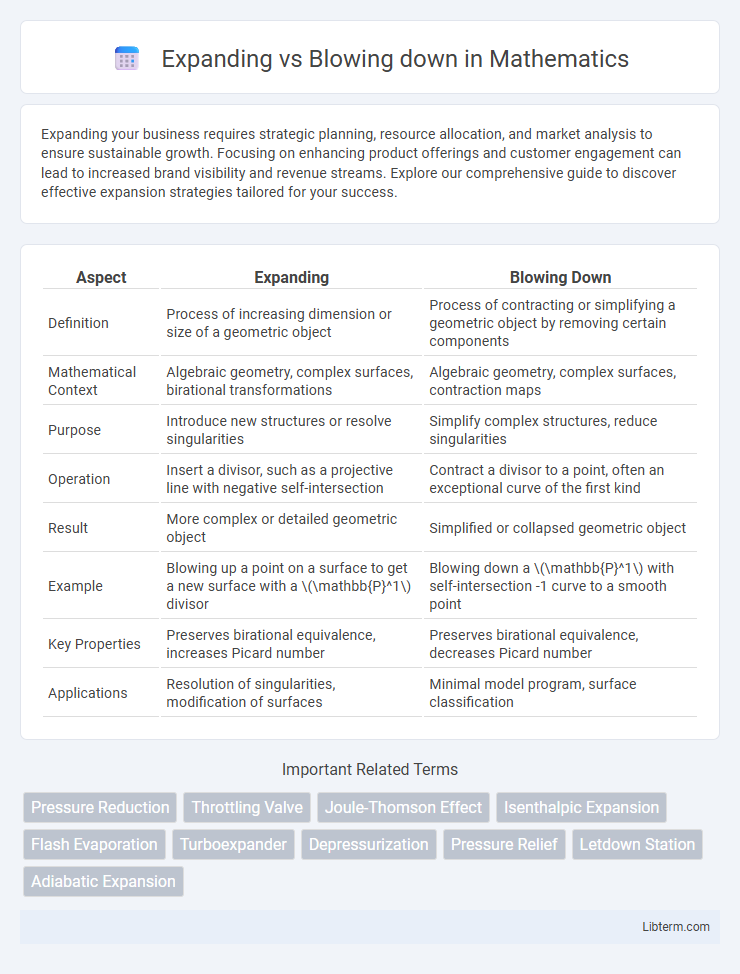

| Aspect | Expanding | Blowing Down |

|---|---|---|

| Definition | Process of increasing dimension or size of a geometric object | Process of contracting or simplifying a geometric object by removing certain components |

| Mathematical Context | Algebraic geometry, complex surfaces, birational transformations | Algebraic geometry, complex surfaces, contraction maps |

| Purpose | Introduce new structures or resolve singularities | Simplify complex structures, reduce singularities |

| Operation | Insert a divisor, such as a projective line with negative self-intersection | Contract a divisor to a point, often an exceptional curve of the first kind |

| Result | More complex or detailed geometric object | Simplified or collapsed geometric object |

| Example | Blowing up a point on a surface to get a new surface with a \(\mathbb{P}^1\) divisor | Blowing down a \(\mathbb{P}^1\) with self-intersection -1 curve to a smooth point |

| Key Properties | Preserves birational equivalence, increases Picard number | Preserves birational equivalence, decreases Picard number |

| Applications | Resolution of singularities, modification of surfaces | Minimal model program, surface classification |

Introduction to Expanding and Blowing Down

Expanding and blowing down are critical processes in industrial gas management, particularly in power plants and manufacturing sectors. Expanding involves increasing the volume of gas to reduce pressure and temperature without losing energy, often using expansion turbines for energy recovery. Blowing down is the controlled release of pressure from a system to prevent damage or maintain safety, typically resulting in the venting of gases to the atmosphere or flaring systems.

Key Differences Between Expanding and Blowing Down

Expanding involves increasing the volume or capacity of a system by adding energy or material, often used in processes like gas expansion or material stretching, whereas blowing down refers to the controlled removal of impurities or excess substances, typically in boilers or industrial equipment to maintain efficiency. Key differences include their purpose--expanding aims at growth or volume increase, while blowing down focuses on cleaning or pressure regulation. Expanding impacts operational capacity, whereas blowing down is essential for system safety and performance stability.

Principles of Gas Expansion Processes

Expanding and blowing down are two key gas expansion processes distinguished by pressure and temperature dynamics. Expanding involves reducing gas pressure through a controlled valve or turbine, causing the gas temperature to drop due to the Joule-Thomson effect and resulting in energy extraction in turbines. Blowing down rapidly releases high-pressure gas to the atmosphere, causing pressure to decrease but often leading to less controlled temperature changes and energy losses.

Blowing Down: Process and Applications

Blowing down involves the controlled release of steam or gases from a pressurized system to reduce pressure, remove impurities, or maintain operational safety. This process is critical in power plants and boilers to prevent scale buildup, mitigate corrosion, and ensure efficient heat transfer. Industrial applications include steam turbines, pressure vessels, and heat exchangers, where blowing down maintains equipment integrity and operational efficiency.

Thermodynamic Effects in Expansion vs Blowing Down

Expanding gas through a turbine results in work extraction and a temperature drop due to the conversion of internal energy into mechanical energy, following isentropic or near-isentropic behavior. Blowing down, or rapid depressurization through a valve, involves irreversible throttling with no work output, causing a nearly constant enthalpy process and often resulting in a temperature decrease due to the Joule-Thomson effect. The fundamental thermodynamic difference lies in expansion producing useful work and temperature changes governed by entropy variation, while blowing down is an irreversible throttling process with enthalpy constant and potential cooling or heating depending on the gas properties.

Equipment Used in Expansion and Blowdown Operations

Expansion operations typically utilize expansion tanks, pressure vessels, and control valves designed to manage increased volume and pressure during thermal or fluid expansion processes. Blowdown operations employ blowdown valves, separators, and flare systems that safely release excess pressure and remove impurities from steam or gas systems. Equipment selection directly influences operational efficiency, safety compliance, and maintenance demands in industrial applications.

Safety Considerations for Expanding and Blowing Down

Expanding and blowing down processes demand stringent safety measures to prevent equipment damage and ensure personnel protection. Expanding involves controlled pressure and temperature changes, requiring precise monitoring to avoid material failure due to thermal stress or overpressure. Blowing down necessitates proper venting and containment systems to safely release pressure, preventing hazardous gas exposure and minimizing environmental impact.

Industrial Applications: Choosing the Right Method

Expanding and blowing down are critical methods in industrial process management for pressure regulation and system maintenance. Expanding is often preferred in energy recovery systems, such as gas turbines and refrigeration cycles, where harnessing work from expansion improves efficiency. Blowing down is essential in boiler operation and compressor systems to safely relieve pressure and remove contaminants, ensuring equipment safety and longevity.

Energy Efficiency: Expansion vs Blowing Down

Expansion processes in industrial systems recover energy by allowing high-pressure fluids to perform work as they drop in pressure, improving overall efficiency. Blowing down releases high-pressure steam or gas to reduce system pressure rapidly but results in significant energy loss as heat and sound. Prioritizing expansion valves or turbines over blowdown valves enhances energy efficiency by capturing useful work instead of wasting it.

Conclusion: Optimal Strategies for Gas Handling

Expanding gas through turbines maximizes energy recovery by converting pressure into mechanical work, enhancing overall system efficiency. Blowing down, while faster and safer for pressure relief, results in energy loss and increased emissions. Optimal gas handling balances expansion for energy savings with controlled blowdown procedures to maintain safety and operational reliability.

Expanding Infographic

libterm.com

libterm.com