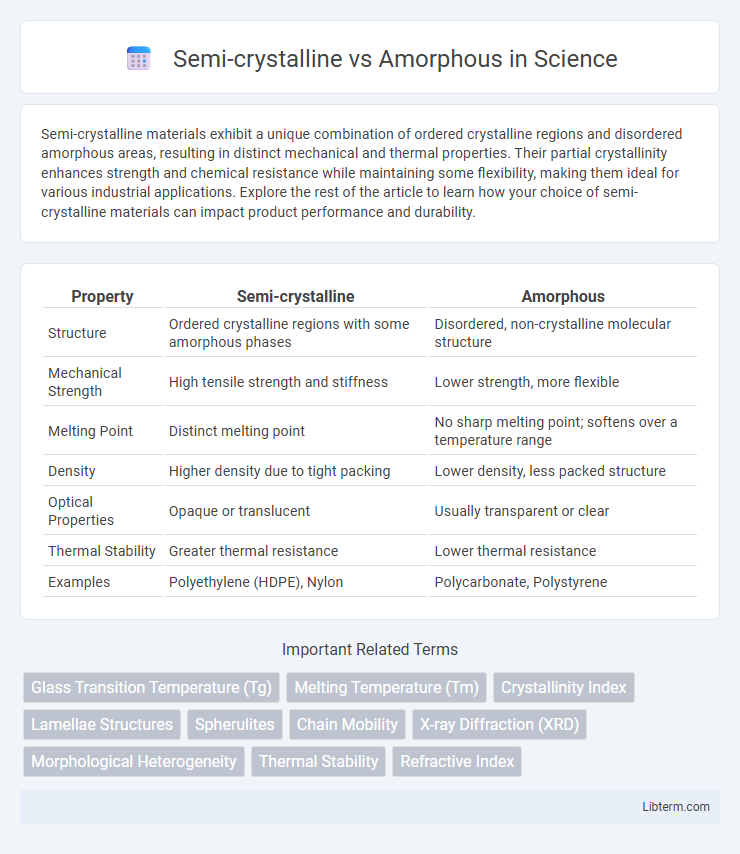

Semi-crystalline materials exhibit a unique combination of ordered crystalline regions and disordered amorphous areas, resulting in distinct mechanical and thermal properties. Their partial crystallinity enhances strength and chemical resistance while maintaining some flexibility, making them ideal for various industrial applications. Explore the rest of the article to learn how your choice of semi-crystalline materials can impact product performance and durability.

Table of Comparison

| Property | Semi-crystalline | Amorphous |

|---|---|---|

| Structure | Ordered crystalline regions with some amorphous phases | Disordered, non-crystalline molecular structure |

| Mechanical Strength | High tensile strength and stiffness | Lower strength, more flexible |

| Melting Point | Distinct melting point | No sharp melting point; softens over a temperature range |

| Density | Higher density due to tight packing | Lower density, less packed structure |

| Optical Properties | Opaque or translucent | Usually transparent or clear |

| Thermal Stability | Greater thermal resistance | Lower thermal resistance |

| Examples | Polyethylene (HDPE), Nylon | Polycarbonate, Polystyrene |

Introduction to Polymer Structures

Polymer structures are categorized into semi-crystalline and amorphous types based on molecular arrangement and degree of order. Semi-crystalline polymers exhibit tightly packed, regularly ordered regions called crystallites, resulting in enhanced density, melting points, and mechanical strength. In contrast, amorphous polymers lack long-range order, with random, disordered molecular chains that provide transparency, flexibility, and impact resistance.

Defining Semi-Crystalline Polymers

Semi-crystalline polymers exhibit a well-ordered molecular structure characterized by both crystalline and amorphous regions, resulting in higher density and improved mechanical properties compared to fully amorphous polymers. These materials show distinct melting points due to their crystalline regions, which contribute to enhanced thermal resistance and chemical stability. Common examples include polyethylene, polypropylene, and nylon, widely used in applications requiring durability and dimensional stability.

Overview of Amorphous Polymers

Amorphous polymers consist of randomly arranged molecular chains, resulting in a non-crystalline, transparent structure with isotropic properties. These polymers exhibit lower density and melting points than semi-crystalline polymers, offering enhanced flexibility and impact resistance but reduced tensile strength. Common examples include polystyrene (PS), polycarbonate (PC), and polymethyl methacrylate (PMMA), widely used in applications requiring clarity and toughness.

Molecular Arrangement: Key Differences

Semi-crystalline polymers exhibit a highly ordered molecular arrangement with regions of tightly packed chains forming crystalline domains, providing enhanced mechanical strength and thermal resistance. In contrast, amorphous polymers display a random, disordered molecular structure lacking defined crystalline regions, resulting in greater flexibility and transparency but lower density and melting points. The degree of crystallinity significantly influences properties such as stiffness, chemical resistance, and optical clarity in polymer materials.

Thermal Properties Comparison

Semi-crystalline polymers exhibit higher melting temperatures and greater thermal stability due to their ordered molecular structure, which allows for distinct melting points. Amorphous polymers lack a well-defined melting point and instead soften over a broad temperature range, characterized by their glass transition temperature (Tg). The thermal conductivity of semi-crystalline materials is generally higher than that of amorphous polymers, resulting in improved heat resistance and dimensional stability under thermal stress.

Mechanical Properties: Strength and Flexibility

Semi-crystalline materials exhibit higher mechanical strength and rigidity due to their ordered molecular structure, enabling better load distribution and resistance to deformation. Amorphous materials, characterized by a random molecular arrangement, provide greater flexibility and impact resistance but generally have lower tensile strength. The balance between strength and flexibility depends on the degree of crystallinity, influencing applications in engineering plastics and polymer composites.

Optical Characteristics: Transparency and Clarity

Semi-crystalline materials exhibit partial transparency with a hazy or translucent appearance due to their ordered crystalline regions scattering light, reducing clarity. Amorphous materials provide superior optical clarity and high transparency because of their random molecular structure, allowing light to pass through with minimal scattering. The degree of crystallinity directly impacts light transmission, making amorphous polymers preferred for applications demanding clear and transparent materials.

Processing and Manufacturing Considerations

Semi-crystalline polymers exhibit higher melting points and greater chemical resistance, requiring precise temperature control during injection molding and extrusion to ensure proper crystallization and mechanical properties. Amorphous polymers, lacking a defined melting point, process within a glass transition temperature range, enabling easier thermoforming and rapid cooling that reduces cycle times in manufacturing. Processing parameters like cooling rate, mold design, and annealing significantly influence the dimensional stability and final performance of both polymer types in industrial applications.

Common Applications and Industry Uses

Semi-crystalline polymers like polyethylene and nylon are widely used in automotive parts, packaging films, and medical devices due to their high strength, thermal resistance, and chemical stability. Amorphous polymers such as polystyrene and polycarbonate find applications in optical lenses, electronic housings, and adhesive products, owing to their transparency, toughness, and ease of processing. Industries including aerospace, electronics, and consumer goods rely on the specific mechanical and thermal properties of these polymers to optimize product performance and durability.

Choosing the Right Polymer for Your Needs

Semi-crystalline polymers exhibit high tensile strength, chemical resistance, and thermal stability due to their ordered molecular structure, making them ideal for applications requiring durability and mechanical performance. Amorphous polymers feature random molecular arrangements, providing transparency, flexibility, and ease of processing suited for optical components and impact-resistant parts. Selecting between semi-crystalline and amorphous polymers depends on factors such as mechanical stress, thermal requirements, chemical exposure, and desired aesthetic properties.

Semi-crystalline Infographic

libterm.com

libterm.com