Symmetric designs balance elements evenly, creating visual harmony and stability in art, architecture, and technology. This principle enhances aesthetic appeal and functionality by ensuring all parts correspond equally on either side of a central axis. Discover how symmetry influences your environment and its impact by reading the rest of the article.

Table of Comparison

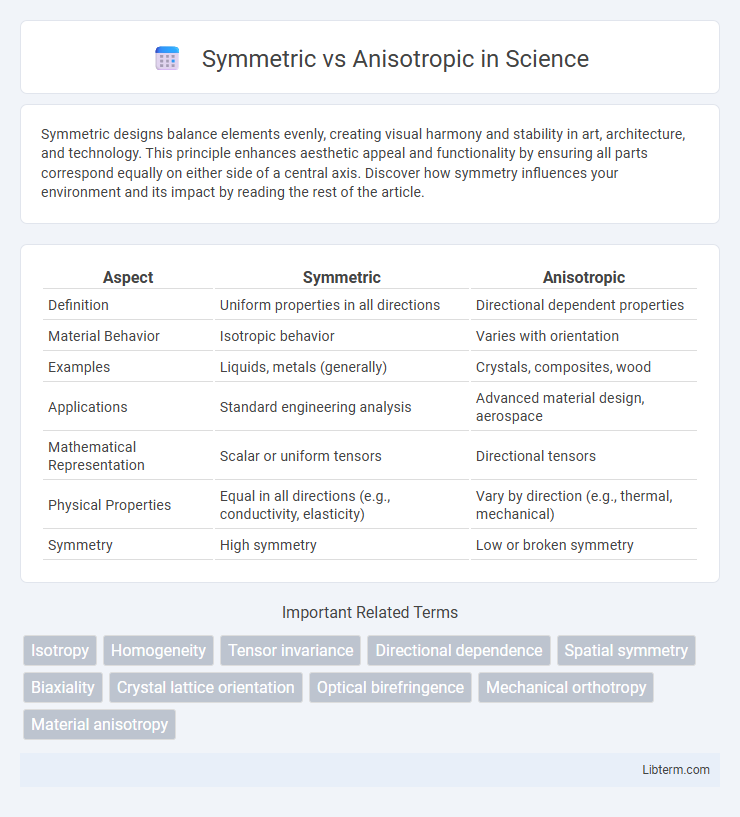

| Aspect | Symmetric | Anisotropic |

|---|---|---|

| Definition | Uniform properties in all directions | Directional dependent properties |

| Material Behavior | Isotropic behavior | Varies with orientation |

| Examples | Liquids, metals (generally) | Crystals, composites, wood |

| Applications | Standard engineering analysis | Advanced material design, aerospace |

| Mathematical Representation | Scalar or uniform tensors | Directional tensors |

| Physical Properties | Equal in all directions (e.g., conductivity, elasticity) | Vary by direction (e.g., thermal, mechanical) |

| Symmetry | High symmetry | Low or broken symmetry |

Understanding Symmetric and Anisotropic: Core Definitions

Symmetric materials exhibit uniform properties in all directions, meaning their mechanical, thermal, or optical characteristics remain consistent regardless of orientation. Anisotropic materials display direction-dependent behavior, with properties varying based on the specific axis or plane measured. Understanding symmetric versus anisotropic properties is crucial in fields like materials science, physics, and engineering, as it impacts material performance and application suitability.

Key Differences Between Symmetric and Anisotropic Properties

Symmetric properties exhibit uniform behavior in all directions, characterized by consistent physical or geometric attributes regardless of orientation. Anisotropic properties vary depending on direction, showing distinct differences in characteristics such as conductivity, strength, or refractive index along different axes. The key difference lies in directional dependence, where symmetric systems are isotropic and anisotropic systems possess directional variability affecting material performance and analysis.

Common Applications of Symmetric Materials

Symmetric materials are commonly used in applications such as optical lenses, aerospace components, and electronic devices where uniform mechanical properties and predictable stress distribution are critical. These materials provide consistent performance due to their isotropic nature, making them ideal for structural elements that require durability and reliability under multidirectional forces. Engineering designs often incorporate symmetric materials in automotive parts and civil infrastructure to optimize strength and longevity.

Practical Uses of Anisotropic Materials

Anisotropic materials exhibit direction-dependent properties, making them ideal for applications such as aerospace components, where strength and stiffness vary based on load orientation. These materials enhance the performance of electronic devices by improving thermal conductivity along specific paths, crucial for efficient heat dissipation. Compared to symmetric materials, anisotropic substances enable tailored mechanical and thermal behaviors in advanced engineering and technology fields.

Physical and Mechanical Implications

Symmetric materials exhibit uniform physical and mechanical properties in all directions, resulting in predictable stress distribution and deformation behavior under load. Anisotropic materials display direction-dependent characteristics, which influence their strength, stiffness, and failure modes, making them suitable for applications requiring tailored mechanical performance. Understanding the anisotropy in composites and crystals is critical for optimizing structural design and ensuring reliability in engineering systems.

Role in Material Science and Engineering

Symmetric materials exhibit uniform properties in all directions, making them ideal for applications requiring consistent mechanical strength and predictable behavior under stress. Anisotropic materials possess direction-dependent properties, enabling engineers to tailor materials for enhanced performance in specific orientations, such as composites in aerospace and automotive industries. Understanding the distinction between symmetric and anisotropic behavior is crucial for optimizing material selection, structural design, and performance in advanced engineering applications.

Symmetry vs. Directionality: Impact on Performance

Symmetric materials exhibit uniform properties in all directions, enabling predictable and consistent performance under varied conditions. In contrast, anisotropic materials display direction-dependent characteristics, which can be engineered to enhance performance in specific orientations, such as improved strength or thermal conductivity. Understanding the symmetry versus directionality relationship is critical for optimizing material selection in applications requiring targeted mechanical, thermal, or electrical properties.

Examples in Nature and Technology

Symmetric structures, like bubbles and snowflakes, exhibit uniform properties in all directions, providing stability and predictability in natural and technological contexts. Anisotropic materials, such as wood and liquid crystals, show direction-dependent characteristics crucial for applications like composite construction and display technologies. In nature, anisotropy influences plant growth and animal movement, while symmetric patterns often govern crystal and mineral formations.

Choosing Between Symmetric and Anisotropic in Design

Choosing between symmetric and anisotropic designs depends on the specific application requirements and material properties. Symmetric designs offer uniform behavior and stress distribution, ideal for applications needing isotropic strength and stability. Anisotropic designs provide directional properties and enhanced performance in targeted orientations, making them suitable for specialized functions where strength or conductivity varies with direction.

Future Trends and Innovations in Material Symmetry

Future trends in material symmetry emphasize advanced anisotropic designs enabling tailored mechanical, electrical, and thermal properties through directional control at the nanoscale. Innovations in metamaterials exploit asymmetric unit cells to achieve unprecedented functionalities like negative refraction and programmable elasticity. Machine learning algorithms accelerate the discovery of materials with optimal symmetry configurations, driving breakthroughs in aerospace, electronics, and energy storage applications.

Symmetric Infographic

libterm.com

libterm.com