Heat exchangers efficiently transfer thermal energy between fluids, enhancing industrial processes and HVAC systems by improving energy conservation and system performance. Their designs vary from shell-and-tube to plate and fin types, tailored to specific temperature and pressure requirements. Discover how selecting the right heat exchanger can optimize your system's efficiency by reading the full article.

Table of Comparison

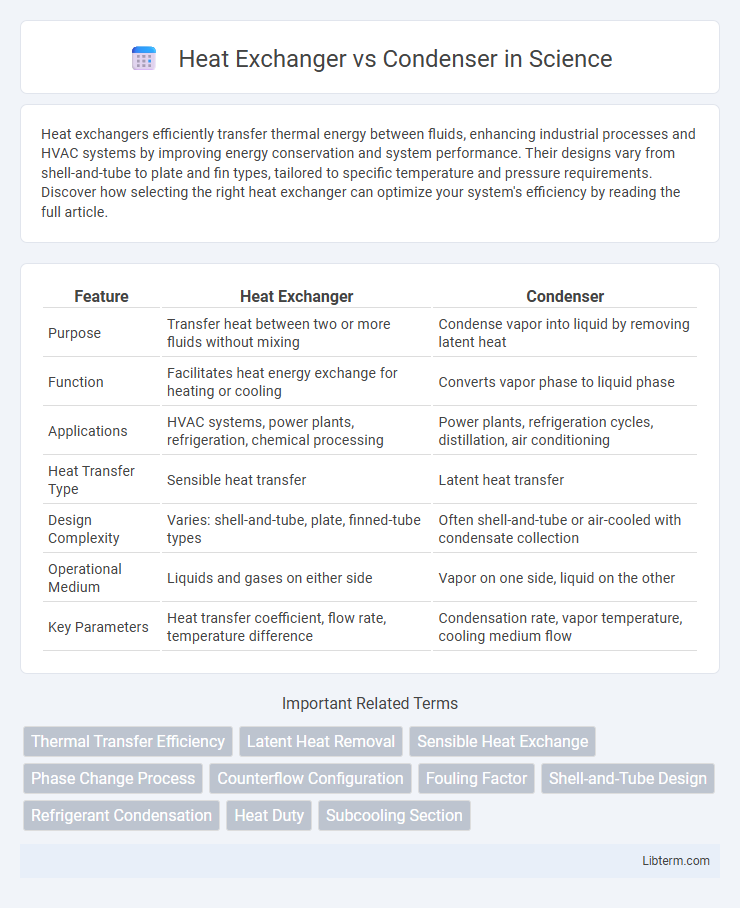

| Feature | Heat Exchanger | Condenser |

|---|---|---|

| Purpose | Transfer heat between two or more fluids without mixing | Condense vapor into liquid by removing latent heat |

| Function | Facilitates heat energy exchange for heating or cooling | Converts vapor phase to liquid phase |

| Applications | HVAC systems, power plants, refrigeration, chemical processing | Power plants, refrigeration cycles, distillation, air conditioning |

| Heat Transfer Type | Sensible heat transfer | Latent heat transfer |

| Design Complexity | Varies: shell-and-tube, plate, finned-tube types | Often shell-and-tube or air-cooled with condensate collection |

| Operational Medium | Liquids and gases on either side | Vapor on one side, liquid on the other |

| Key Parameters | Heat transfer coefficient, flow rate, temperature difference | Condensation rate, vapor temperature, cooling medium flow |

Introduction to Heat Exchanger and Condenser

Heat exchangers and condensers are essential components in thermal systems designed to transfer heat efficiently between fluids. Heat exchangers facilitate the transfer of thermal energy without mixing the fluids, optimizing energy use in industries like HVAC, power generation, and chemical processing. Condensers specifically convert vapor into liquid by removing latent heat, playing a critical role in refrigeration cycles and steam power plants.

Definition and Basic Principles

A heat exchanger is a device designed to transfer heat between two or more fluids without mixing them, using conduction and convection principles to efficiently manage thermal energy. A condenser, a specific type of heat exchanger, functions to convert vapor into liquid by removing latent heat through condensation, commonly used in refrigeration and power plants. Both devices operate on fundamental thermodynamic principles but serve distinct roles based on their phase change application and heat transfer mechanisms.

Key Differences Between Heat Exchangers and Condensers

Heat exchangers transfer heat between two or more fluids without mixing them, enabling temperature regulation in various industrial processes. Condensers specifically convert vapor into liquid by removing latent heat, primarily used in refrigeration and power plants. The key difference lies in their function: heat exchangers facilitate general heat transfer, while condensers perform phase change by condensing vapor to liquid.

Main Components and Construction

Heat exchangers primarily consist of a shell, tubes or plates, and fluid inlets/outlets designed to transfer heat between two or more fluids efficiently. Condensers, a specialized type of heat exchanger, feature a tube bundle or plate arrangement where vapor condenses into liquid by losing heat, often incorporating cooling water or air flow systems. Both rely on robust materials like stainless steel or copper for corrosion resistance, with condensers typically including additional components such as condensate collection trays and enhanced surface area for improved phase change heat transfer.

Working Mechanism of Heat Exchangers

Heat exchangers operate by transferring thermal energy between two or more fluids at different temperatures without mixing them, using conduction and convection through a solid barrier such as tubes or plates. In contrast, condensers specifically facilitate the phase change of vapor into liquid by removing latent heat, typically employing cooling water or air to absorb heat from the vapor. The working mechanism of heat exchangers involves maximizing surface area and fluid flow arrangements (counterflow, parallel flow, or crossflow) to enhance heat transfer efficiency.

Function and Operation of Condensers

Condensers function by transferring heat from a vapor to a cooling medium, typically converting steam or refrigerant vapor into liquid through condensation, which enables efficient heat rejection in systems such as HVAC, power plants, and refrigeration units. They operate by facilitating latent heat release at constant pressure, enhancing system efficiency by maintaining a low-pressure environment in the turbine exhaust or refrigeration cycle. In contrast, general heat exchangers transfer heat between two fluids without phase change, serving a broader range of thermal management applications.

Common Applications in Industry

Heat exchangers and condensers both play critical roles in industrial processes, with heat exchangers commonly used for transferring heat between fluids in power plants, chemical processing, and HVAC systems. Condensers are specialized heat exchangers primarily employed in steam power generation, refrigeration, and petrochemical industries to condense vapor into liquid by removing latent heat. Their applications are essential for energy efficiency, temperature regulation, and phase change management in various industrial operations.

Advantages and Limitations

Heat exchangers efficiently transfer heat between two fluids without mixing, offering versatility in applications like HVAC, power plants, and chemical processing, with advantages including energy savings and temperature control. Condensers specifically convert vapor into liquid by removing latent heat, providing crucial advantages in refrigeration and steam power cycles by enhancing system efficiency and preventing equipment damage. However, heat exchangers can be limited by fouling and pressure drops, while condensers require proper maintenance to avoid corrosion and maintain optimal condensation rates.

Selection Criteria: When to Use Each

Selecting between a heat exchanger and a condenser depends on the specific temperature and phase change requirements of the process. Heat exchangers are ideal for applications requiring efficient heat transfer between fluids without phase change, such as in heating or cooling liquids, while condensers are specifically designed to condense vapor into liquid by removing latent heat. Factors like operating temperature, pressure conditions, space constraints, and the nature of fluids involved dictate the optimal choice for effective thermal management.

Summary and Final Comparison

Heat exchangers transfer heat between two or more fluids without mixing, optimizing energy efficiency in HVAC, chemical, and industrial processes. Condensers specifically cool vapor into liquid, playing a critical role in refrigeration, power plants, and distillation systems by removing latent heat. The primary difference lies in application: heat exchangers serve broad heat transfer needs, while condensers specialize in phase change cooling, making each essential for distinct thermal management tasks.

Heat Exchanger Infographic

libterm.com

libterm.com