Metallic materials exhibit unique properties such as high electrical conductivity, malleability, and durability, making them ideal for a wide range of industrial and technological applications. Understanding the characteristics and uses of different metals can help you select the best material for your specific needs. Explore the rest of this article to discover how metallic elements shape modern innovation and design.

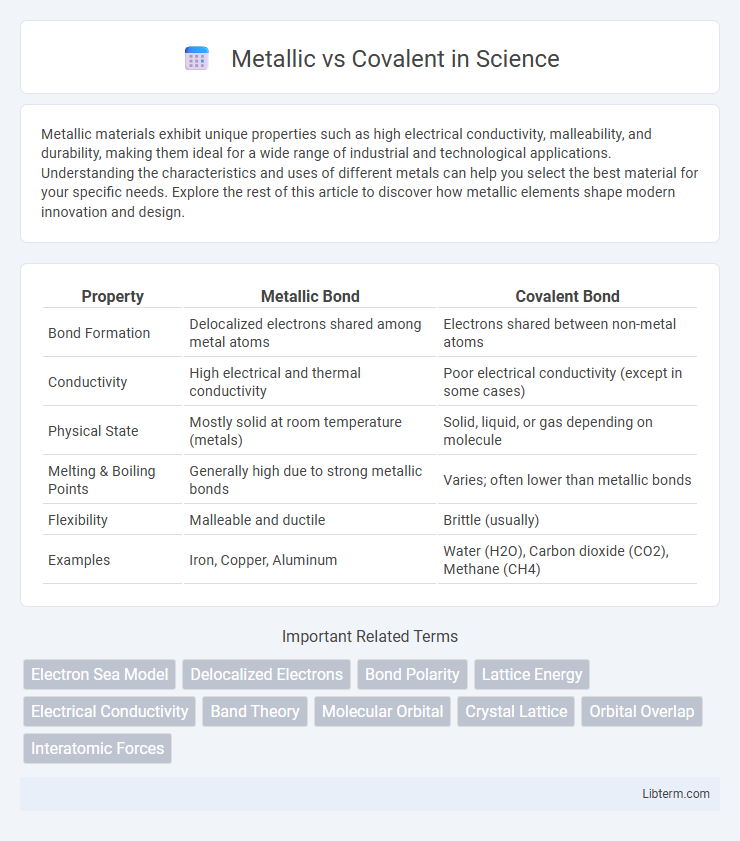

Table of Comparison

| Property | Metallic Bond | Covalent Bond |

|---|---|---|

| Bond Formation | Delocalized electrons shared among metal atoms | Electrons shared between non-metal atoms |

| Conductivity | High electrical and thermal conductivity | Poor electrical conductivity (except in some cases) |

| Physical State | Mostly solid at room temperature (metals) | Solid, liquid, or gas depending on molecule |

| Melting & Boiling Points | Generally high due to strong metallic bonds | Varies; often lower than metallic bonds |

| Flexibility | Malleable and ductile | Brittle (usually) |

| Examples | Iron, Copper, Aluminum | Water (H2O), Carbon dioxide (CO2), Methane (CH4) |

Introduction to Chemical Bonding

Metallic bonds involve the delocalization of electrons across a lattice of metal atoms, resulting in conductive and malleable materials, while covalent bonds form through the sharing of electron pairs between nonmetal atoms, creating distinct molecules with specific shapes. The strength and nature of these bonds influence physical properties such as melting point, electrical conductivity, and hardness. Understanding the contrast between metallic and covalent bonding is essential for explaining the behavior of metals versus molecular compounds in chemical bonding.

Overview of Metallic Bonds

Metallic bonds are characterized by a lattice of positively charged metal ions surrounded by a sea of delocalized electrons, allowing for high electrical and thermal conductivity. These bonds create strong cohesion in metal crystals while enabling malleability and ductility because the electron cloud can shift without breaking the overall structure. The strength and mobility of metallic bonds contrast with the directional nature of covalent bonds, which involve electron sharing between specific atoms.

Overview of Covalent Bonds

Covalent bonds form when atoms share electron pairs to achieve stable electron configurations, typically occurring between nonmetal atoms. This type of bond creates molecules with specific shapes and distinct physical properties such as low melting points and poor electrical conductivity in solid state. Covalent bonding plays a critical role in organic compounds, polymers, and biological molecules by enabling strong directional interactions between atoms.

Electron Behavior in Metallic vs Covalent Bonds

In metallic bonds, electrons form a delocalized electron cloud that freely moves throughout the metal lattice, resulting in high electrical conductivity and malleability. Covalent bonds involve the sharing of electrons between specific atoms, creating localized electron pairs that contribute to molecule stability and directional bonding. This fundamental difference in electron behavior underpins the contrasting physical properties of metals and covalent compounds.

Physical Properties Comparison

Metallic bonds exhibit high electrical and thermal conductivity due to free-moving delocalized electrons, while covalent bonds generally show poor conductivity because electrons are localized between atoms. Metals possess malleability and ductility resulting from the flexible electron sea, contrasting with the brittleness and low malleability of covalent compounds. Melting and boiling points vary; metals often have moderate to high values, whereas covalent substances display a broad range depending on molecular size and structure.

Electrical and Thermal Conductivity

Metallic bonds allow free electrons to move easily, resulting in excellent electrical and thermal conductivity in metals such as copper and silver. Covalent bonds involve shared electron pairs localized between atoms, which restrict electron mobility and lead to poor conductivity in substances like diamond and silicon dioxide. The delocalized electron cloud in metallic structures facilitates efficient energy transfer, unlike the strong directional bonds in covalent networks that hinder conduction.

Strength and Malleability

Metallic bonds exhibit high malleability due to the delocalized electrons that allow metal atoms to slide past each other without breaking the bond, resulting in strong yet flexible structures. Covalent bonds, characterized by shared electron pairs between specific atoms, typically form rigid and strong but brittle materials with low malleability. The strength in metallic bonds arises from the electron sea model, while covalent bonds gain strength from localized electron sharing, directly impacting the physical properties like malleability and hardness.

Common Examples and Applications

Metallic bonds are commonly found in elements such as iron, copper, and aluminum, widely used in construction, electrical wiring, and transportation due to their excellent conductivity and malleability. Covalent bonds are characteristic of molecules like water (H2O), carbon dioxide (CO2), and organic compounds, playing a crucial role in biological systems, pharmaceuticals, and polymer materials. Common applications of metallic bonds involve metal alloys and electrical components, while covalent bonds are fundamental in chemical synthesis, drug design, and the development of advanced materials like plastics and semiconductors.

Advantages and Disadvantages

Metallic bonds offer excellent electrical conductivity and malleability due to the free movement of delocalized electrons, but they can be prone to corrosion and loss of strength at high temperatures. Covalent bonds create strong, stable compounds with high melting points and low electrical conductivity, yet these materials tend to be brittle and less ductile. Both bonding types influence material properties critically in applications ranging from electronics to structural components.

Conclusion: Choosing the Right Bond Type

Choosing the right bond type depends on the desired properties and applications: metallic bonds offer high electrical conductivity and malleability ideal for electrical wiring and structural materials, while covalent bonds provide strong, directional connections suitable for molecules requiring specific shapes and stability, such as in polymers and biological compounds. Understanding the differences in electron sharing and bonding strength allows scientists to tailor materials for electrical, mechanical, and chemical performance. Selection hinges on balancing conductivity, flexibility, and chemical reactivity to meet specific industrial or technological needs.

Metallic Infographic

libterm.com

libterm.com