Polycrystalline materials consist of numerous small crystals or grains, which influence their mechanical and electrical properties. These structures are common in metals, ceramics, and semiconductors, offering a balance between strength and conductivity. Explore the rest of the article to understand how polycrystalline materials impact your technology and industry applications.

Table of Comparison

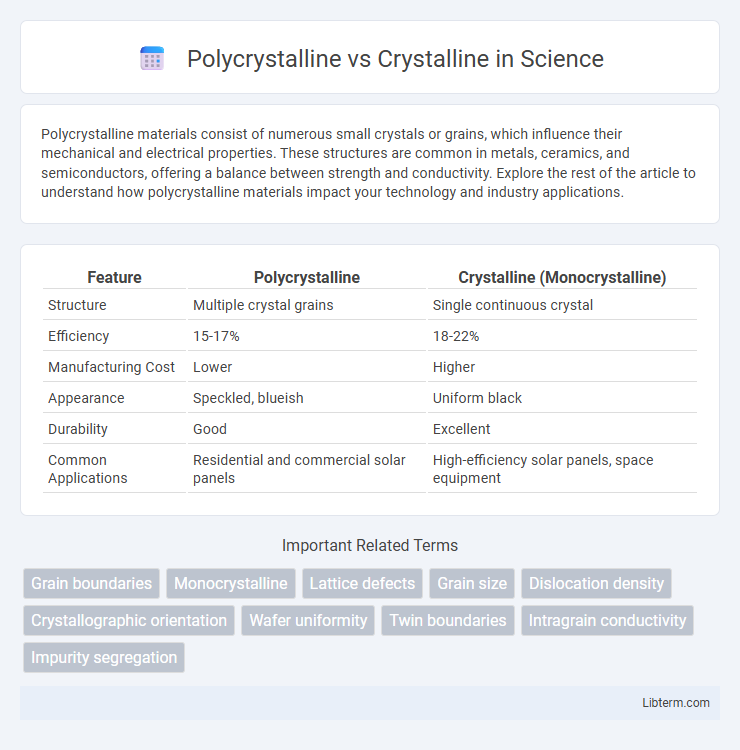

| Feature | Polycrystalline | Crystalline (Monocrystalline) |

|---|---|---|

| Structure | Multiple crystal grains | Single continuous crystal |

| Efficiency | 15-17% | 18-22% |

| Manufacturing Cost | Lower | Higher |

| Appearance | Speckled, blueish | Uniform black |

| Durability | Good | Excellent |

| Common Applications | Residential and commercial solar panels | High-efficiency solar panels, space equipment |

Introduction to Solar Cell Types

Polycrystalline solar cells, made from multiple silicon crystals, offer cost-effective energy solutions with slightly lower efficiency compared to monocrystalline cells, which are formed from a single continuous silicon crystal and provide higher efficiency and durability. Monocrystalline solar panels feature uniform dark appearance and better space efficiency, ideal for limited rooftop areas, while polycrystalline panels display a bluish, fragmented texture due to their crystal structure. Selection depends on budget, installation space, and energy goals, with monocrystalline preferred for higher performance and polycrystalline favored for affordability.

Understanding Polycrystalline Solar Panels

Polycrystalline solar panels consist of multiple silicon crystals melted together, resulting in a distinctive blue color with visible crystal boundaries, while crystalline (monocrystalline) panels are made from a single silicon crystal, offering higher efficiency and a uniform black appearance. Polycrystalline panels provide a cost-effective solution with slightly lower efficiency, often ranging between 13-16%, compared to monocrystalline panels that typically achieve 15-20% efficiency. Understanding the material structure and manufacturing processes helps in choosing polycrystalline solar panels for budget-sensitive installations that prioritize affordability over maximum energy output.

Overview of Monocrystalline Solar Panels

Monocrystalline solar panels are composed of single-crystal silicon, offering higher efficiency and better performance in low-light conditions compared to polycrystalline panels. Their uniform dark appearance and higher purity silicon grant them superior energy conversion rates, typically around 15-20%. These panels are ideal for limited space installations due to their higher power output per square foot.

Key Differences Between Polycrystalline and Crystalline

Polycrystalline materials consist of multiple small crystals or grains, resulting in grain boundaries that can affect electrical and mechanical properties, while crystalline materials, often single-crystal, have a continuous and unbroken lattice structure with superior structural uniformity. Polycrystalline silicon is commonly used in solar panels due to lower production costs but lower efficiency compared to monocrystalline silicon, which offers higher purity and better electron mobility. The grain boundaries in polycrystalline materials can cause increased resistance and reduced thermal conductivity, influencing performance in electronic and photovoltaic applications.

Efficiency Comparison: Polycrystalline vs Crystalline

Crystalline solar panels, specifically monocrystalline types, typically achieve higher efficiency rates of 15-20% due to their uniform silicon structure, while polycrystalline panels average 13-16% efficiency because of multiple silicon crystals causing electron flow disruption. The superior efficiency of monocrystalline cells results in better performance in space-constrained installations and higher energy output per square meter. Despite lower efficiency, polycrystalline panels are often preferred for their lower production costs and slightly better performance in high-temperature environments.

Cost Analysis of Each Solar Technology

Polycrystalline solar panels generally cost 10-20% less than monocrystalline panels due to simpler manufacturing processes and less silicon purity requirement. Monocrystalline panels offer higher efficiency, around 15-20%, which can reduce long-term energy costs despite their higher initial price. The choice between polycrystalline and monocrystalline technology hinges on balancing upfront investment with energy output and efficiency savings.

Durability and Lifespan Considerations

Polycrystalline solar panels typically offer a balance between cost and durability, with a moderate lifespan averaging around 25 years, while monocrystalline panels, known for their higher purity silicon structure, provide enhanced durability and a longer lifespan often exceeding 30 years. The crystalline structure in monocrystalline panels contributes to better resistance against environmental stressors such as heat and moisture, which can degrade panel performance over time. Choosing monocrystalline panels can result in more consistent energy output and lower maintenance costs, making them a preferred option for long-term solar investments.

Visual and Aesthetic Differences

Polycrystalline solar panels exhibit a speckled, bluish hue due to the multiple silicon crystals fused together, creating a grainy texture that reflects light unevenly. Monocrystalline panels feature a uniform deep black color with a smooth surface, resulting from a single continuous silicon crystal, which provides a sleek and modern aesthetic. These visual distinctions influence design choices in architecture, where the darker, uniform look of monocrystalline panels often complements minimalist styles, while polycrystalline's textured appearance suits more varied or rustic settings.

Ideal Applications for Each Panel Type

Polycrystalline solar panels excel in residential and commercial installations where cost-effectiveness and moderate efficiency are prioritized, making them ideal for large rooftop arrays and solar farms. Monocrystalline panels, known for higher efficiency and better performance in low-light conditions, suit applications requiring maximum energy output in limited space, such as urban rooftops and portable solar devices. Both types provide reliable renewable energy solutions, but selection depends on balancing performance needs and budget constraints.

Making the Right Choice: Factors to Consider

Choosing between polycrystalline and monocrystalline solar panels depends on factors such as efficiency, cost, and available installation space. Monocrystalline panels offer higher efficiency and better performance in low-light conditions, while polycrystalline panels are typically more affordable and have a lower environmental impact during manufacturing. Assessing energy needs, budget constraints, and aesthetic preferences helps determine the optimal solar panel type for residential or commercial use.

Polycrystalline Infographic

libterm.com

libterm.com