Brittle materials are prone to sudden fracture without significant deformation, making them susceptible to cracking under stress. Understanding the causes and characteristics of brittleness is crucial for selecting the right materials in engineering and manufacturing. Discover how brittleness affects your projects by reading the rest of this article.

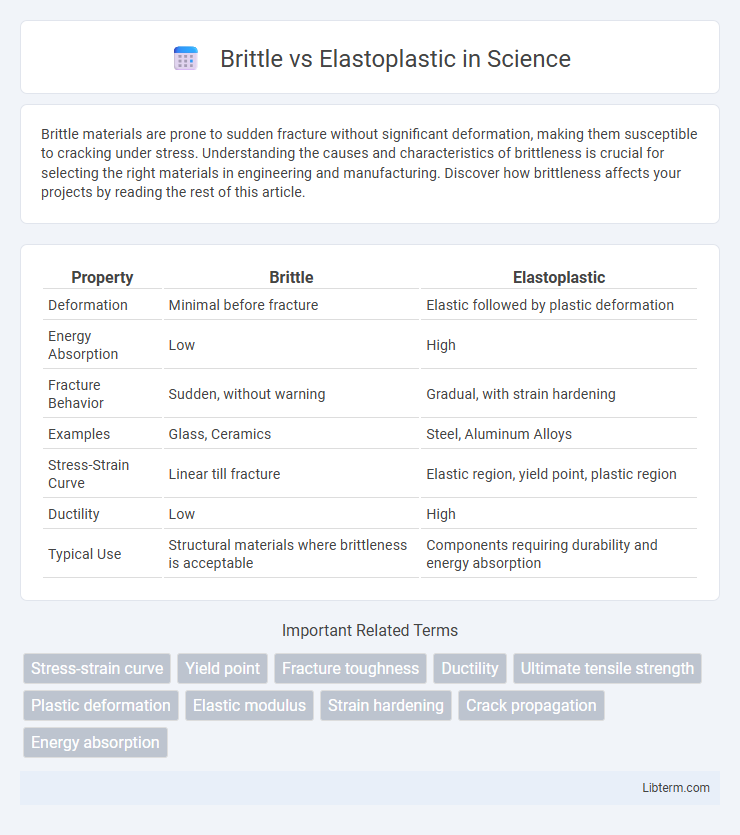

Table of Comparison

| Property | Brittle | Elastoplastic |

|---|---|---|

| Deformation | Minimal before fracture | Elastic followed by plastic deformation |

| Energy Absorption | Low | High |

| Fracture Behavior | Sudden, without warning | Gradual, with strain hardening |

| Examples | Glass, Ceramics | Steel, Aluminum Alloys |

| Stress-Strain Curve | Linear till fracture | Elastic region, yield point, plastic region |

| Ductility | Low | High |

| Typical Use | Structural materials where brittleness is acceptable | Components requiring durability and energy absorption |

Introduction to Material Behavior

Brittle materials fracture without significant plastic deformation, exhibiting limited energy absorption before failure, while elastoplastic materials undergo both elastic and plastic deformation, allowing them to absorb energy through permanent shape changes. Understanding the stress-strain relationship is crucial, as brittle materials show a linear elastic region until fracture, whereas elastoplastic materials exhibit a nonlinear curve with yielding and strain hardening phases. These differences directly impact failure modes and design considerations in engineering applications, influencing safety, durability, and material selection.

Defining Brittle Materials

Brittle materials are characterized by their inability to undergo significant plastic deformation before fracturing, often failing suddenly under stress. These materials typically exhibit high strength but low toughness, making them prone to crack propagation. In contrast, elastoplastic materials possess both elastic and plastic deformation capabilities, allowing them to absorb energy and deform permanently without immediate breakage.

Characteristics of Elastoplastic Materials

Elastoplastic materials exhibit both elastic and plastic deformation, allowing them to return to their original shape under low stress and undergo permanent deformation when stress exceeds the yield point. These materials have a defined yield strength, after which they display strain hardening, improving resistance to further deformation. Elastoplastic behavior is critical in engineering applications requiring materials that absorb energy and deform without sudden failure, contrasting the brittle materials that fracture with minimal plastic deformation.

Key Differences Between Brittle and Elastoplastic

Brittle materials fracture without significant plastic deformation, characterized by low ductility and sudden failure under stress, whereas elastoplastic materials exhibit both elastic deformation and permanent plastic deformation before failure. The key differences include their stress-strain behavior: brittle materials have a linear elastic region followed by fracture, while elastoplastic materials show a yield point, strain hardening, and gradual failure. Brittle materials are typically ceramics and glass, while elastoplastic behavior is common in metals and polymers, influencing their applications in structural design and manufacturing processes.

Stress-Strain Curves: Brittle vs Elastoplastic

Brittle materials exhibit a linear stress-strain curve up to fracture, showing minimal plastic deformation and a sudden failure at maximum stress. Elastoplastic materials display an initial linear elastic region followed by a nonlinear plastic deformation phase, with permanent strain remaining after unloading. The distinct stress-strain behavior highlights brittleness as characterized by high strength and low ductility, whereas elastoplasticity combines elastic recovery with irreversible plastic flow.

Applications of Brittle Materials

Brittle materials, such as ceramics, glass, and concrete, are extensively used in applications requiring high compressive strength and hardness, including construction, aerospace components, and electronics. Their inability to undergo significant plastic deformation makes them ideal for wear-resistant surfaces, cutting tools, and thermal insulators. Despite low tensile strength, their durability and resistance to corrosion are advantageous in environments where minimal deformation is critical.

Uses and Advantages of Elastoplastic Materials

Elastoplastic materials are widely used in automotive components and structural engineering due to their ability to withstand significant plastic deformation without fracturing, providing enhanced durability and safety. These materials offer advantages such as improved energy absorption and resistance to impact compared to brittle materials, which are prone to sudden failure. Applications in metal forming and machine parts benefit from elastoplastic properties, ensuring components can endure repeated stress cycles while maintaining integrity.

Factors Influencing Material Selection

Material selection between brittle and elastoplastic substances hinges on factors such as mechanical stress, environmental conditions, and desired durability. Brittleness is preferable in applications requiring high hardness and wear resistance but involves risk of sudden failure under impact, while elastoplastic materials offer better energy absorption and deformation capacity, crucial in dynamic or cyclic loading scenarios. Cost, availability, and manufacturing processes also play critical roles in determining the optimal material for specific engineering applications.

Common Testing Methods for Material Behavior

Common testing methods for brittle materials include the Charpy impact test and tensile testing to evaluate fracture toughness and tensile strength, revealing the material's tendency to crack without significant plastic deformation. Elastoplastic materials are often assessed using uniaxial tensile tests and cyclic loading tests to determine yield strength, strain hardening, and hysteresis behavior, capturing their ability to deform plastically before failure. Both types benefit from fracture toughness tests like the J-integral method for detailed analysis of crack propagation under different loading conditions.

Conclusion: Choosing the Right Material

Selecting the right material between brittle and elastoplastic types depends on the application's stress conditions and desired deformation behavior. Brittle materials excel in high-strength, low-deformation contexts but fail abruptly under tensile stress, while elastoplastic materials offer ductility and energy absorption through plastic deformation. Understanding the operational environment and failure modes ensures optimal material performance and safety in engineering designs.

Brittle Infographic

libterm.com

libterm.com